Preparation method of two-dimensional nano polymer composite wire suitable for 3D printing

A two-dimensional nanomaterial and two-dimensional nanotechnology, applied in the field of two-dimensional nano-polymer composite wire and its preparation, can solve the problems of no two-dimensional nano-polymer composite material, and achieve improved uniformity, improved performance, and improved compactness effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] A method for preparing a two-dimensional nano-polymer composite filament suitable for 3D printing in this embodiment, the specific steps are as follows:

[0038] (1) Preparation of two-dimensional nano-polymer composite film: The two-dimensional nano-polymer composite film is prepared by centrifugal casting method, and the preparation process is as follows:

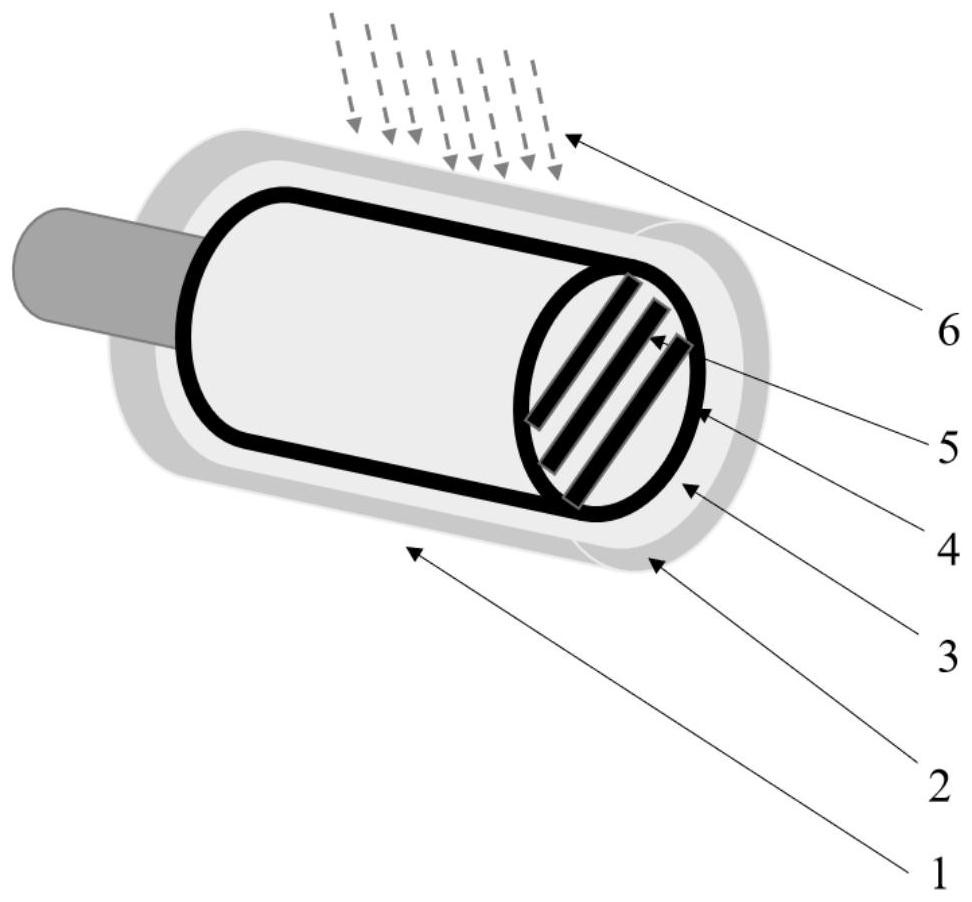

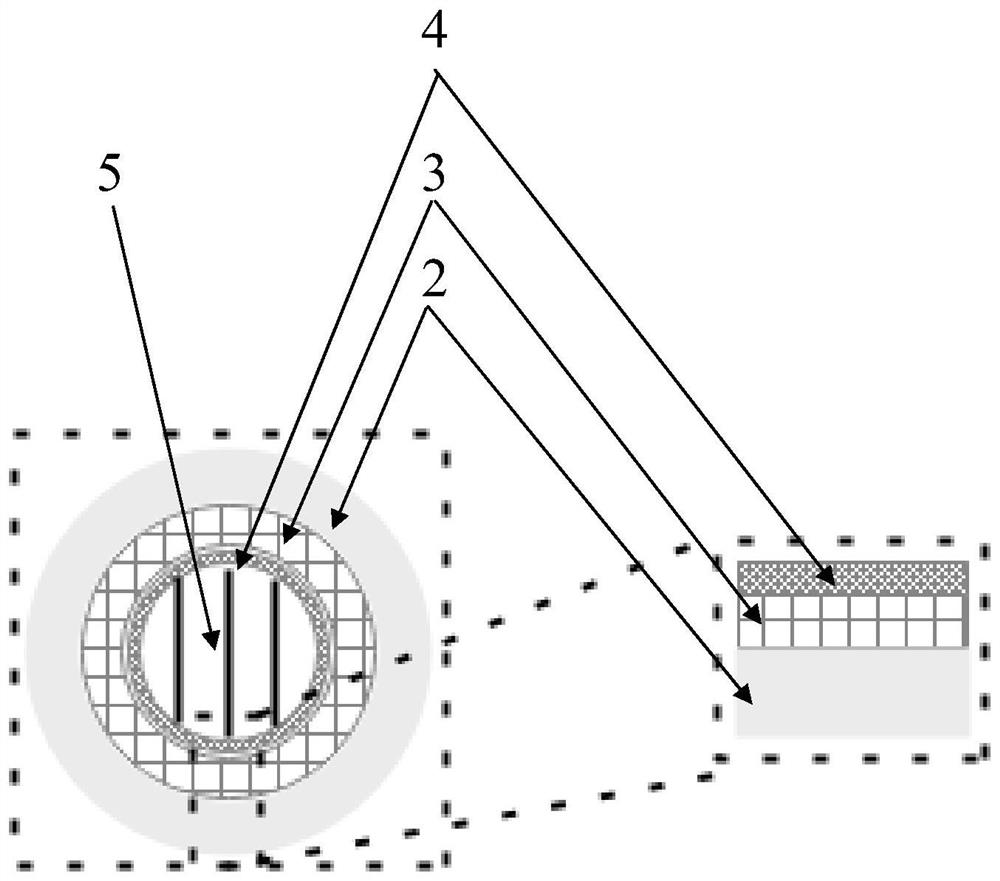

[0039] ①The mold rotates circularly at high speed. The cylindrical centrifuge tube, sand core filter layer and nanofiltration membrane rotate at high speed in the circumferential direction, and the inner layer of the smooth inner surface of the centrifuge tube is respectively attached with a layer of sand core filter layer and nanofiltration membrane.

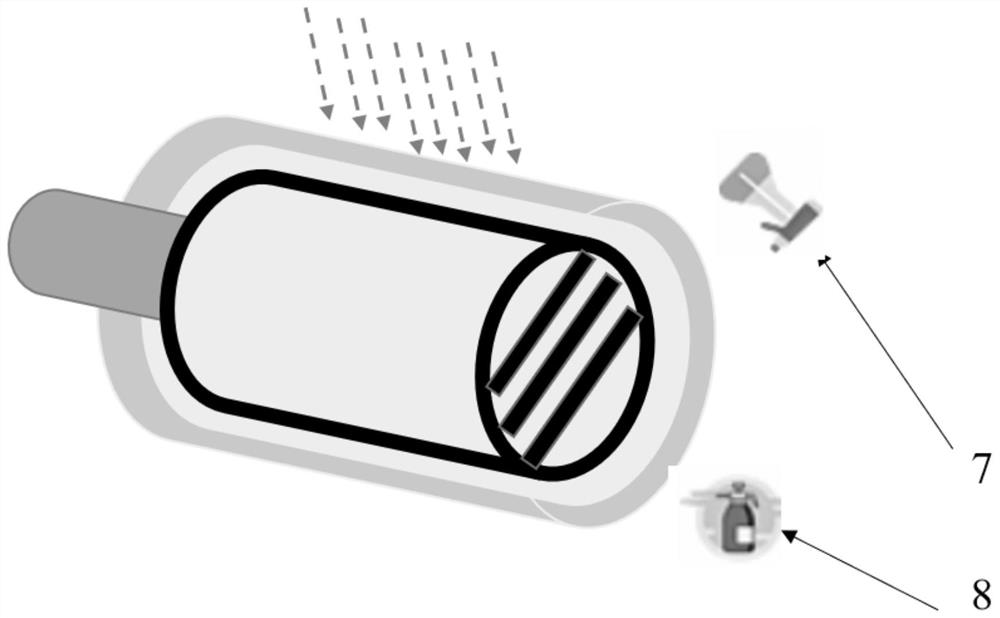

[0040] ② The solution is alternately sprayed back and forth. The prepared two-dimensional nanomaterial solution 7 is evenly sprayed on the inner surface of the high-speed circularly rotating mold in step ①, and the relative motion between the liquid layers forms a ...

Embodiment 2

[0047] In this embodiment, the material of the cylindrical centrifuge tube is glass tube, the material of the filter layer of the sand core is quartz, the material of the nanofiltration membrane is PVC, and the pore diameter is 4 mm. The rotation speed of the mold is 1500r / min. The two-dimensional nanomaterial is graphene oxide with a solubility of 10 mg / ml, and the polymer solution is polyurethane with a concentration of 6 mg / g. The graphene oxide and polyurethane solution are alternately sprayed layer by layer. The auxiliary heating temperature was set at 80° C. to obtain a multi-layer laminated two-dimensional nano-polymer composite film with a thickness of 15 μm. The distance between the blades set at the opening of the mold and perpendicular to the central axis of the centrifuge tube is 1.0 mm, and finally a two-dimensional nano-polymer composite filament suitable for 3D printing is obtained. The strength of the filament is about 52 MPa, and the in-plane and vertical cond...

Embodiment 3

[0049] In this embodiment, the material of the cylindrical centrifuge tube is glass tube, the material of the filter layer of the sand core is quartz, the material of the nanofiltration membrane is PVC, and the pore diameter is 5 mm. The rotation speed of the mold is 1000r / min. The two-dimensional nanomaterial is graphene oxide with a solubility of 10 mg / ml, and the polymer solution is polyurethane with a concentration of 10 mg / g. The graphene oxide and polyurethane solution are alternately sprayed layer by layer. The auxiliary heating temperature was set at 80° C. to obtain a multi-layer laminated two-dimensional nano-polymer composite film with a thickness of 10 μm. The distance between the blades set at the opening of the mold and perpendicular to the central axis of the centrifuge tube is 1.5mm, and finally a two-dimensional nano-polymer composite filament suitable for 3D printing is obtained. The strength of the filament is about 46MPa, and the in-plane and vertical condu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com