Metal oxide nanoparticle and processing method thereof, and QLED device

A nanoparticle and processing method technology, which is applied in the field of metal oxide nanoparticles and its processing method and QLED devices, can solve the problems affecting device life, device preparation repeatability, etc., and achieve the effect of improving efficiency and life, improving efficiency and life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

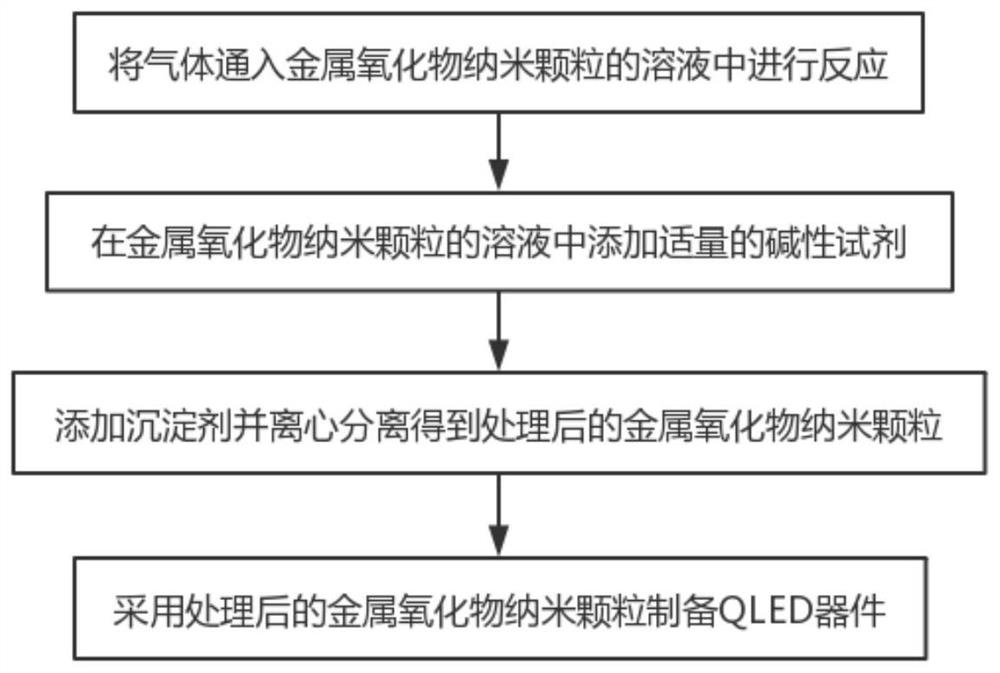

Method used

Image

Examples

Embodiment 1

[0053] In this example, H 2 , ZnO nanoparticles, and KOH as an example to prepare a QLED, which specifically includes the following steps:

[0054] 1) Preparation of ZnO nanoparticles:

[0055] Take 0.5g of zinc acetate hydrate and disperse in 20ml of dimethyl sulfoxide to form a clear solution, take 0.3g of tetramethylammonium hydroxide and disperse in 30ml of ethanol solution; mix the two solutions together and stir for 30min Perform high-speed centrifugation to prepare ZnO solid nanoparticles, and then configure a certain concentration of ZnO nanoparticle solution (30mg / ml, solution: ethanol).

[0056] 2) Using H 2 Treatment of ZnO nanoparticles:

[0057] Get above-mentioned prepared ZnO nanoparticle solution 2ml (30mg / ml, solution: ethanol), under the protection of an inert atmosphere, pass into 1mol of H in the ZnO nanoparticle solution 2 , the access time is 30min.

[0058] 3) To H 2 Add KOH to the treated ZnO nanoparticles solution:

[0059] Take 0.1 mmol of KOH ...

Embodiment 2

[0064] In this example, O 2 , NiO nanoparticles, and ammonia water as an example to prepare a QLED, which specifically includes the following steps:

[0065] 1) Prepare a solution of NiO nanoparticles in a conventional manner:

[0066] 2) Use O 2 Treatment of NiO nanoparticles:

[0067] Take 2ml (30mg / ml, solution: ethanol) of the above-mentioned prepared NiO nanoparticle solution, and under the protection of an inert atmosphere, feed 0.5mol of O into the NiO nanoparticle solution. 2 , the access time is 5min.

[0068] 3) to O 2 Add ammonia solution to the treated NiO nanoparticle solution:

[0069] Take 0.1 mmol of ammonia solution and add it dropwise to the NiO nanoparticle solution in 2), and then stir evenly to form a clear solution for later use.

[0070] 4) Add 30ml of ethyl butyrate to the above solution 3), carry out centrifugation and precipitate, pour off the supernatant, and then disperse the precipitate in 2ml of ethanol for later use.

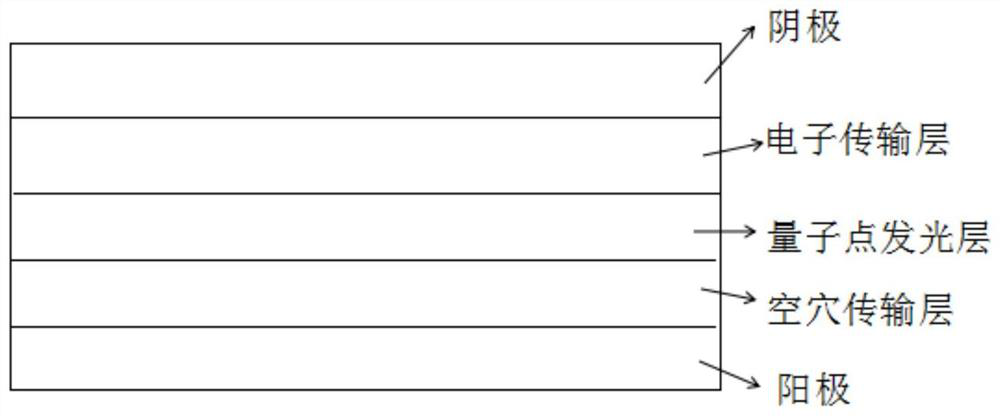

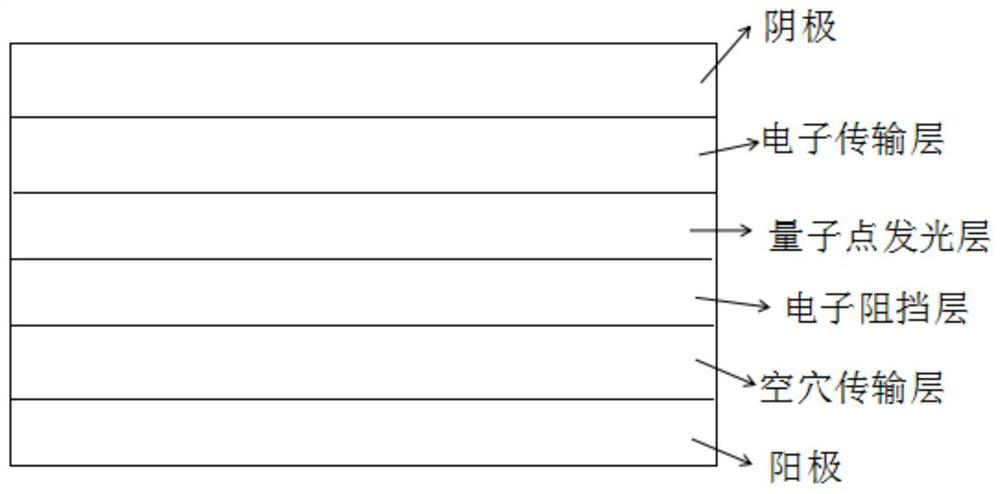

[0071] 5) Preparatio...

Embodiment 3

[0073] In this example, H 2 S, W 2 o 3 Taking nanoparticles and ammonia water as an example to prepare a QLED, it specifically includes the following steps:

[0074] 1) Prepare W in a conventional manner 2 o 3 Solution of nanoparticles:

[0075] 2) Using H 2 S vs. W 2 o 3 Nanoparticles for processing:

[0076] Take the W prepared above 2 o 3 Nanoparticle solution 2ml (30mg / ml, solution: ethanol), under inert atmosphere protection, to W 2 o 3 Add 1 mol of H to the nanoparticle solution 2 S, the access time is 90min.

[0077] 3) To H 2 W after S treatment 2 o 3 Add ammonia solution to nanoparticle solution:

[0078] Get 0.1mmol of ammonia solution and add dropwise to the W in 2) 2 o 3 Nanoparticle solution, then stirred evenly to form a clear solution for later use.

[0079] 4) Add 30ml of ethyl butyrate to the above solution 3), carry out centrifugation and precipitate, pour off the supernatant, and then disperse the precipitate in 2ml of ethanol for later u...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com