Fuel cell cathode catalyst and preparation method thereof, membrane electrode and fuel cell

A fuel cell cathode and catalyst technology, applied in battery electrodes, circuits, electrical components, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

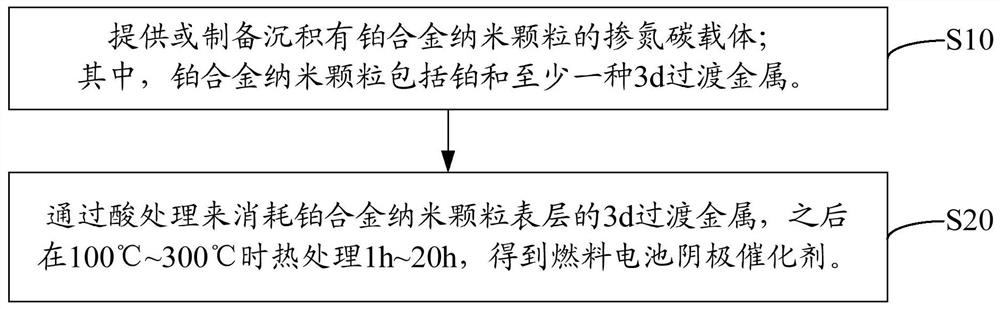

[0035] See figure 1 , the preparation method of fuel cell cathode catalyst of one embodiment of the present invention, comprises the following steps:

[0036] S10. Provide or prepare a nitrogen-doped carbon support deposited with platinum alloy nanoparticles; wherein, the platinum alloy nanoparticles include platinum and at least one 3d transition metal.

[0037] Preferably, the platinum alloy nanoparticles are selected from at least one of platinum-cobalt alloy nanoparticles, platinum-nickel nanoparticles and platinum-iron nanoparticles.

[0038] Preferably, the platinum alloy nanoparticles further include one or both of manganese, iridium, rhodium, niobium and zirconium.

[0039] Preferably, the particle diameter of the platinum alloy nanoparticles ranges from 3nm to 6nm.

[0040] Among them, the 3d transition metal refers to the metal in which the last electron is arranged in the 3d orbital when the electron arrangement of the atom is arranged. Examples include metals su...

Embodiment 1

[0083] 100mg XC-72 carbon carrier (average particle size 2μm, BET 250m 2 / g) in H 2 SO 4 / HNO 3 (v / v=3:1) stirred at room temperature for 2h, then mixed with 200mg H 2 PtCl 6 , 200mg Co(NO 3 ) 2 Add together 50mL ethylene glycol, mix well, then add 50mgNaBH 4 , after sufficient reaction, a carbon support deposited with platinum alloy nanoparticles was obtained.

[0084] After washing and drying the carbon carrier deposited with platinum alloy nanoparticles, the first heat treatment was carried out at 700° C. for 4 hours in an ammonia atmosphere to obtain a product after the first heat treatment.

[0085] The above product was acid-treated in nitric acid with a pH of 1.0 for 2 hours, filtered and washed for a second heat treatment in an argon atmosphere at 250° C. for 1 hour, and the fuel cell cathode catalyst of Example 1 was obtained.

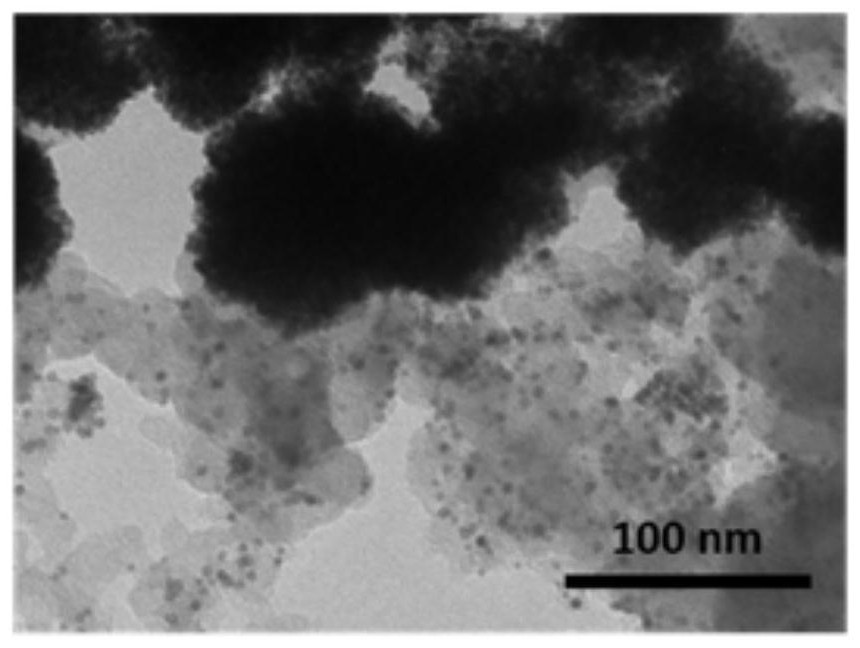

[0086] After characterization, in the obtained fuel cell cathode catalyst, the mass fraction of nitrogen in the nitrogen-doped carbon...

Embodiment 2

[0088] 100mg XC-72 carbon carrier (average particle size 2μm, BET 250m 2 / g) in H 2 SO 4 / HNO 3 (v / v=3:1) stirred at room temperature for 2h, then mixed with 200mg H 2 PtCl 6 , 300mgNiCl 2 Add together 50mL ethylene glycol, mix well, then add 50mgNaBH 4 , after sufficient reaction, a carbon support deposited with platinum alloy nanoparticles was obtained.

[0089] After washing and drying the carbon carrier deposited with platinum alloy nanoparticles, the first heat treatment was carried out at 700° C. for 4 hours in an ammonia atmosphere to obtain a product after the first heat treatment.

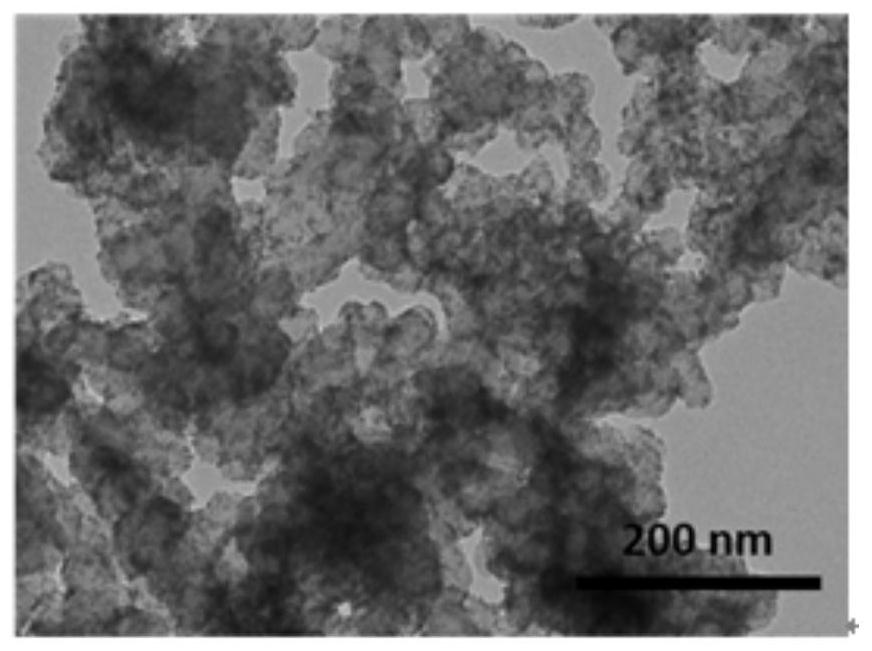

[0090]The above product was acid-treated in nitric acid with a pH of 1.0 for 2 hours, filtered and washed for a second heat treatment in an argon atmosphere at 250° C. for 1 hour, and the fuel cell cathode catalyst of Example 2 was obtained.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Size | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com