Packaged noble metal catalyst for liquid-phase catalytic hydrogenation reduction of Cr (VI) under neutral condition and preparation method and application thereof

A noble metal catalyst, liquid-phase catalysis technology, applied in the direction of physical/chemical process catalysts, molecular sieve catalysts, chemical instruments and methods, etc., can solve the problems of catalyst activity reduction, catalytic hydrogenation reduction Cr limitation, etc., to improve stability and increase The effect of recycling rate, efficient and fast removal or

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

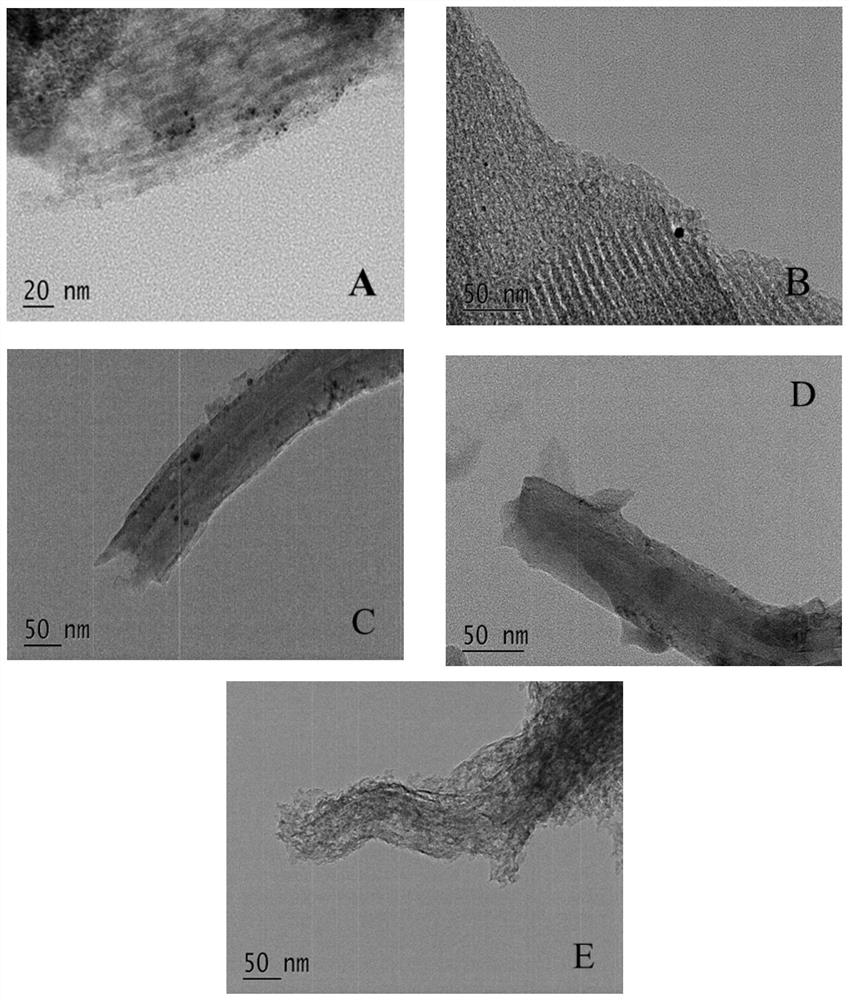

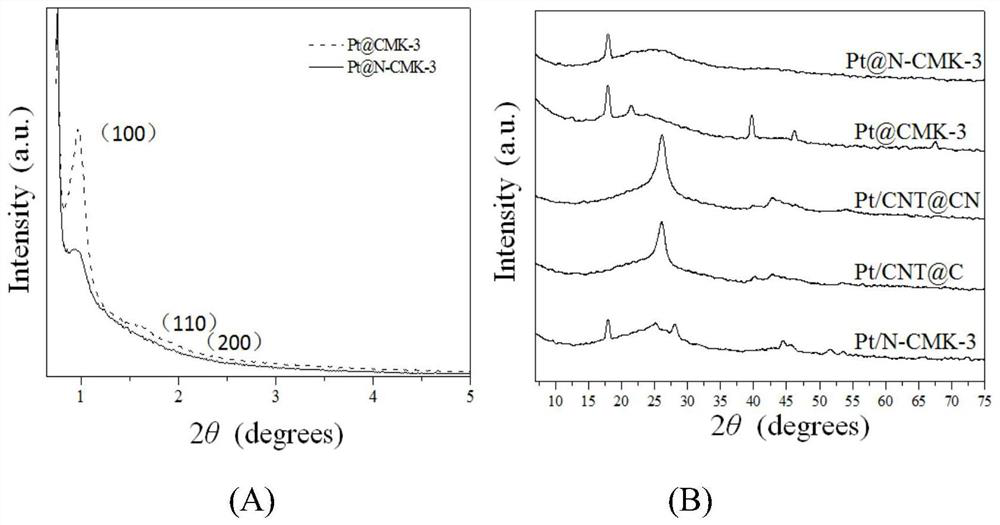

[0048] An encapsulated noble metal catalyst for liquid-phase catalytic reduction of Cr(VI) under neutral conditions and its preparation, the catalyst is an encapsulated type in which platinum is dispersed in a nitrogen-ordered mesoporous carbon (N-CMK-3) framework Pt@N-CMK-3, the platinum loading is 0.5-2.0wt% (mass percentage);

[0049] Prepare described encapsulated noble metal catalyst according to the following steps:

[0050] ① Functionalization of SBA-15 with ammonium persulfate: Use hydrochloric acid solution with a concentration of 0.2g / mL ammonium persulfate and 1.0g of SBA-15 to impregnate in equal volumes, stir and dry at 60-80°C to obtain functionalization The templating agent SBA-15;

[0051] ② Add a certain amount of chloroplatinic acid dropwise to the hydrochloric acid solution of aniline, mix evenly, impregnate with the functionalized SBA-15 in step ① in an equal volume, let stand overnight, place and dry after the aniline is polymerized, and obtain a dry powd...

Embodiment 2

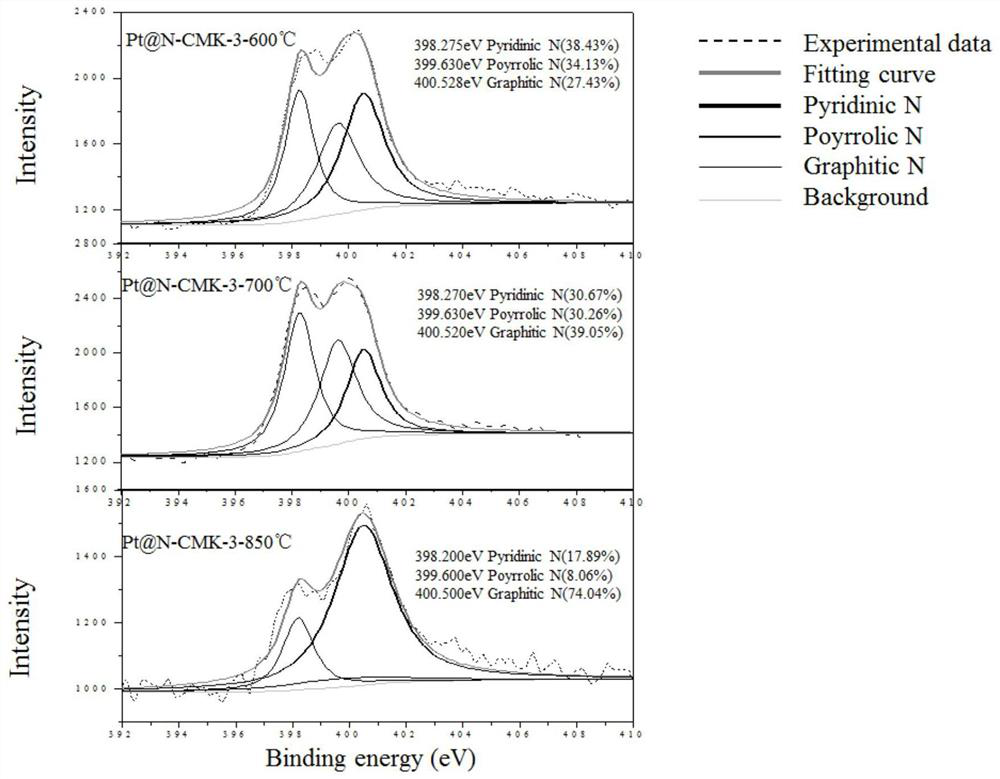

[0078] Prepare the encapsulated platinum-based catalyst Pt@N-CMK-3 according to the catalyst preparation method described in Example 1, the difference is that the calcination temperature is changed to 850°C, 700°C, and 600°C respectively to make the encapsulated platinum-based catalyst Pt@N-CMK-3 N-CMK-3-850°C, Pt@N-CMK-3-700°C, Pt@N-CMK-3-600°C, apply the same conditions as in Example 1 to Cr(VI) under neutral conditions Liquid-phase catalytic hydrogenation reduction.

[0079] The result is as Figure 6 It can be seen that as the calcination temperature increases, the reduction effect of pollutants is better and the initial activity is higher.

Embodiment 3

[0081] Same as Example 1, the catalyst prepared in Example 1 was used to carry out the liquid-phase catalytic hydrogenation reduction reaction of Cr(VI) under neutral conditions. The catalyst uses Pt@N-CMK-3, its concentration is 0.07g / L, 0.125g / L, 0.15g / L, 0.20g / L, the initial concentration of Cr(VI) is 0.5mM, and the reaction pH is 5.6~ 7. The flow rate of hydrogen is 150-200mL / min, and the reaction is carried out at normal temperature and pressure for 2 hours.

[0082] Response curve such as Figure 7 As shown in (A), when the catalyst concentration is 0.20g / L, Cr(VI) is basically reduced after 2 hours of reaction, and the initial activity column diagram is as follows Figure 7 As shown in (B), the initial activity of the catalyst is basically maintained at 20mM gCat -1 h -1 , indicating that there is no mass transfer resistance in the reaction system.

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com