Preparation method for enzymatically-fermented soymilk

An enzymatic hydrolysis and soy milk technology, applied to bacteria, dairy products, milk replacers, etc. used in food preparation, can solve the problems of slow fermentation, unacceptable to consumers, and rough texture of pure plant-based yogurt, so as to control the breeding and reproduction. , to avoid pollution, the effect of delicate taste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

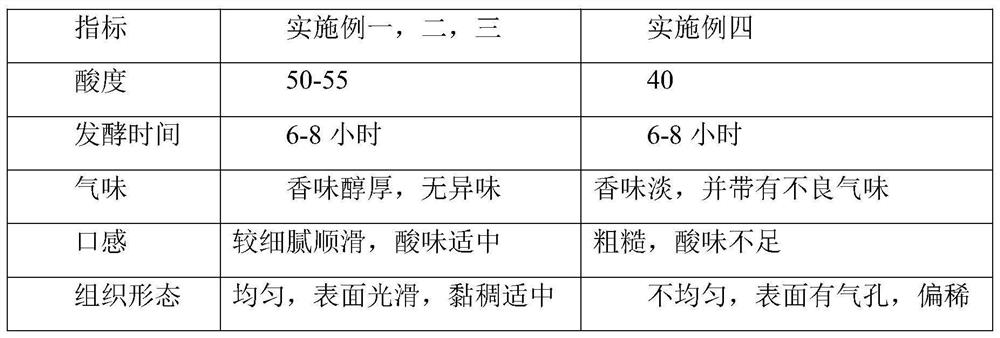

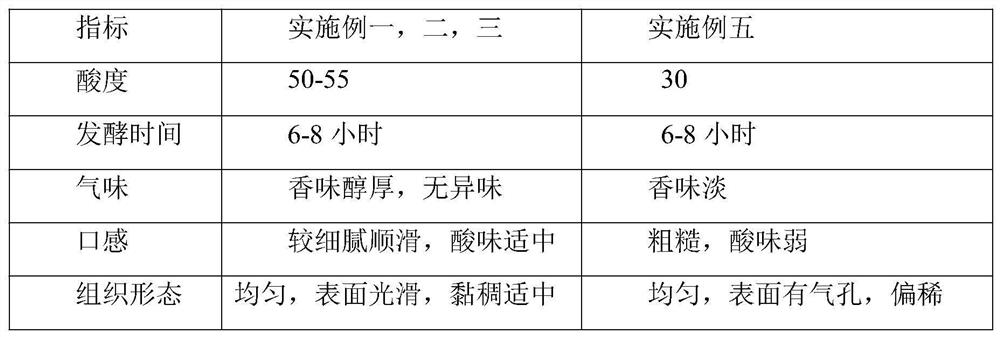

Examples

preparation example Construction

[0023] In order to solve the technical difficulties of pure plant-fermented yogurt of soybean milk products currently on the market, such as low utilization rate of plant protein, slow fermentation speed, susceptibility to pollution, and poor flavor and taste. The application discloses a preparation method of enzymatically hydrolyzed fermented soybean milk, which includes the following steps:

[0024] (1) Washing and soaking: Clean the soybeans, add sodium bicarbonate in water and soak for 4-6 hours; the temperature of the soaking water is 50-60°C, and the content of sodium bicarbonate is 0.5%-1.0% based on the soaking solution.

[0025] (2) Refining: peeling and refining soybeans;

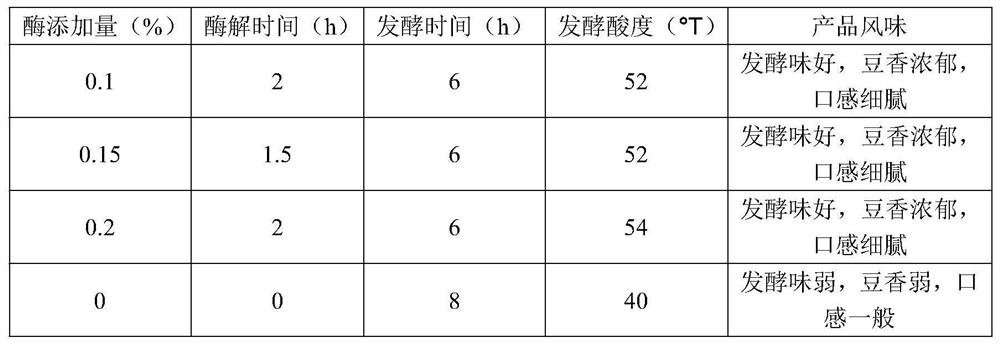

[0026] (3) Enzymatic hydrolysis: use cellulase and protease to form an enzymatic hydrolysis solution, add the enzymatic hydrolysis solution to the soybean milk, adjust the enzymatic hydrolysis temperature to 50-60℃, and continue enzymatic hydrolysis for 1-3 hours; fiber in the enzymatic hydrolysis soluti...

Embodiment 1

[0032] A preparation method of enzymatically fermented soy milk includes the following steps:

[0033] (1) Washing and soaking: The soybeans are cleaned and soaked in water with sodium bicarbonate for 6 hours; the temperature of the soaking water is 50°C, and the content of sodium bicarbonate is 0.5% based on the soaking solution.

[0034] (2) Refining: peeling and refining soybeans;

[0035] (3) Enzymatic hydrolysis: use cellulase and protease to form an enzymatic hydrolysis solution, add the enzymatic hydrolysis solution to the soybean milk, adjust the enzymatic hydrolysis temperature to 55℃, and continue enzymatic hydrolysis for 2 hours; cellulase and protease in the enzymatic hydrolysis solution The ratio is 2:1, the added amount of the enzymatic hydrolysate is based on the finished product, and the enzymatic hydrolysate is added with a mass ratio of 0.1%.

[0036] (4) Blending; adding 8% sugar to blending, homogenizing, homogenizing pressure 30Mpa, homogenizing temperature 65°C, ...

Embodiment 2

[0040] A preparation method of enzymatically fermented soy milk includes the following steps:

[0041] (1) Cleaning and soaking: The soybeans are cleaned and soaked in water with sodium bicarbonate for 4 hours; the temperature of the soaking water is 55°C, and the content of sodium bicarbonate is 0.6% based on the soaking solution.

[0042] (2) Refining: peeling and refining soybeans;

[0043] (3) Enzymatic hydrolysis: use cellulase and protease to form an enzymatic hydrolysis solution, add the enzymatic hydrolysis solution to the soybean milk, adjust the enzymatic hydrolysis temperature to 60 ℃, and continue enzymatic hydrolysis for 1.5 hours; The ratio of the protease is 2:1, and the added amount of the enzymatic hydrolysate is based on the finished product, and the enzymatic hydrolysate is added with a mass ratio of 0.15%.

[0044] (4) Blending; adding 8% sugar to blending, homogenizing, homogenizing pressure 35Mpa, homogenizing temperature 70°C, UHT ultra-high temperature instant ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com