Defoaming agent composition as well as preparation method and application thereof

A technology of composition and defoaming agent, applied in the directions of separation method, chemical instrument and method, foam dispersion/prevention, etc., can solve the problems of poor performance of defoaming agent, inability to lasting foam suppression, etc., to improve rapid defoaming performance, improve acid and alkali resistance, and improve the effect of dispersing speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

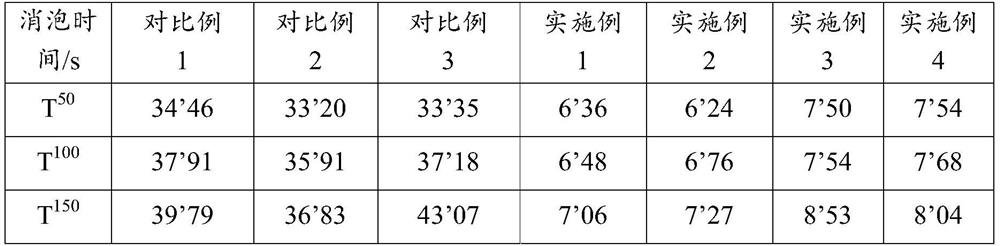

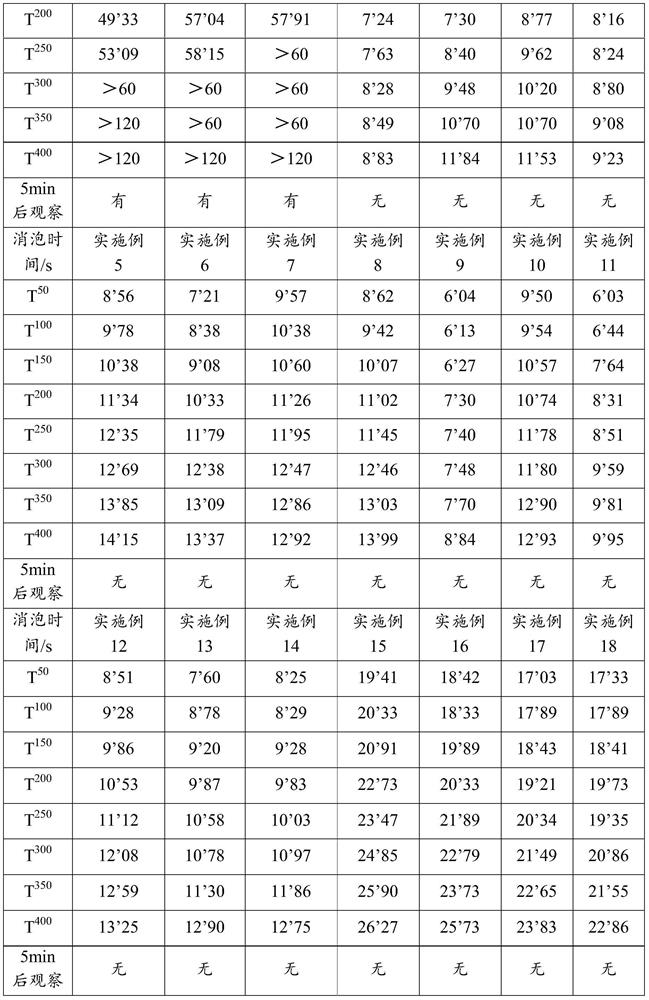

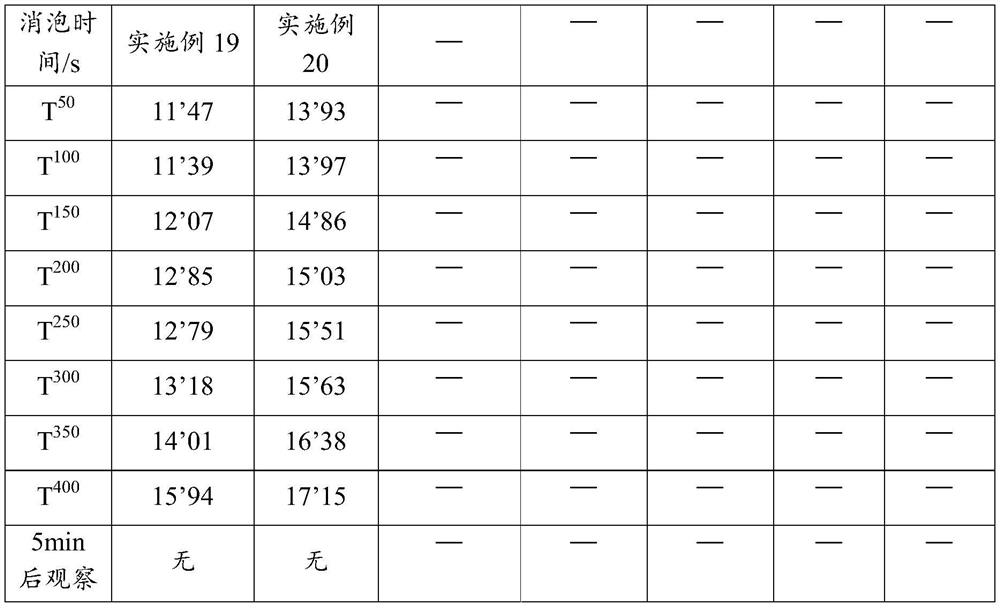

Examples

Embodiment 1

[0065] 1. Preparation of linear silicone paste

[0066] (1) Accurately measure 40g of 350mPa·s simethicone oil, 45g of 500mPa·s simethicone oil into a 250mL four-neck bottle, start stirring and heat up to 50°C, add 10g in batches with a specific surface area of 200m 2 / g of fumed hydrophobic silica and MQ silicone resin (the link M unit is R 3 SiO 1 / 2 , linking Q cells to SiO 4 / 2 , the R group is a methyl group, M / Q=0.8) 5g, after adding, continue to stir and mix for 2h;

[0067] (2) The mixture obtained above was heated to 100° C., 50 microliters of potassium hydroxide isopropanol solution (potassium hydroxide content 15 wt%) was added, and the reaction was continued for 1.5 h;

[0068] (3) Raise the temperature of the material in the reaction bottle to 150° C., further heat treatment for 3 hours, and cool to room temperature to obtain a linear silicone paste.

[0069] 2. Preparation of 3D mesh silicone paste

[0070] (1) Accurately measure 80g of 200mPa·s terminal vin...

Embodiment 2

[0080] 1. Preparation of linear silicone paste

[0081] (1) Accurately measure 85g of 500mPa·s simethicone oil in a 250mL four-neck bottle, start stirring and heat up to 55°C, add 10g in batches with a specific surface area of 200m 2 / g gas-phase method hydrophobic silica and MQ silicone resin (the link M unit is R 3 SiO 1 / 2 , linking Q cells to SiO 4 / 2 , the R group is a methyl group, M / Q=0.8) 5g, after adding, continue to stir and mix for 2h;

[0082] (2) The mixture was heated to 100° C., 50 microliters of potassium hydroxide isopropanol solution (potassium hydroxide content 15 wt%) was added, and the reaction was continued for 1.5 h;

[0083] (3) Raise the temperature of the material in the reaction bottle to 150° C., further heat treatment for 3 hours, and cool to room temperature to obtain a linear silicone paste.

[0084] 2. Preparation of 3D mesh silicone paste

[0085] (1) Accurately measure 80g of 200mPa·s terminal vinyl silicone oil (vinyl content 1.9mol%), 5...

Embodiment 3

[0095] 1. Preparation of linear silicone paste

[0096] (1) Accurately measure 45g of 350mPa·s simethicone oil, 45g of 500mPa·s simethicone oil into a 250mL four-necked bottle, start stirring and heat up to 50°C, add 5g in batches with a specific surface area of 200m 2 / g gas-phase method hydrophobic silica and MQ silicone resin (the link M unit is R 3 SiO 1 / 2 , linking Q cells to SiO 4 / 2 , the R group is a methyl group, M / Q=0.8) 5g, after adding, continue to stir and mix for 2h;

[0097] (2) The mixture obtained above was heated to 110° C., 50 microliters of potassium hydroxide isopropanol solution (potassium hydroxide content 15 wt%) was added, and the reaction was continued for 1.5 h;

[0098] (3) Raise the temperature of the material in the reaction bottle to 150°C, further heat treatment for 3 hours, and cool to room temperature to obtain a linear silicone paste.

[0099] 2. Preparation of 3D mesh silicone paste

[0100] (1) Accurately measure 80g of 200mPa·s termi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com