Salt-tolerant structural polymer emulsion and preparation method thereof

A technology of polymer emulsion and salt resistance, which is applied in the direction of chemical instruments and methods, drilling compositions, etc., can solve the problem that clear water cannot satisfy a large amount of fracturing water, polymer or guar gum has poor salt resistance, and cannot meet pressure requirements. The use of cracking sand-carrying fluid and other problems can be achieved to achieve excellent sand-carrying properties, good salt resistance, and good viscoelasticity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

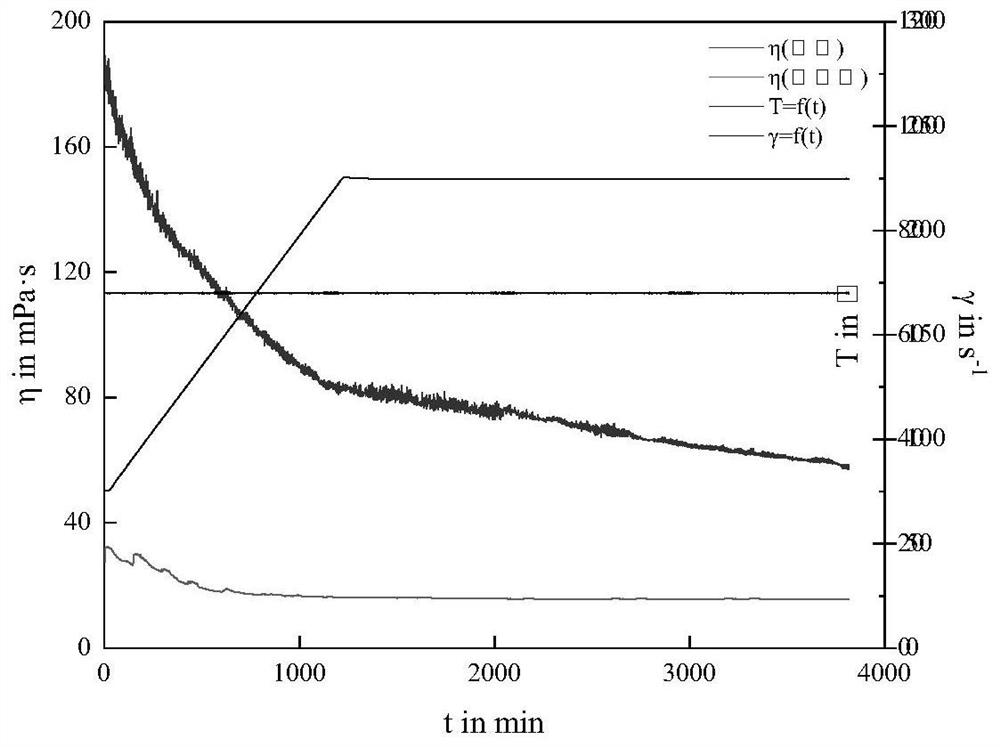

Embodiment 1

[0026] The preparation method of the salt-tolerant structural polymer emulsion provided in this example is: in the jacketed reactor one, add 340g of 3# white oil, 15g of Span 60, 40g of Span 80, and 30g of Tween 80, and start stirring to obtain the oil Phase; add 260g water, 142g acrylamide, 96g acrylic acid, 15g 2-acrylamido-2-methylpropanesulfonic acid, 52g sodium hydroxide to adjust the pH of the solution to 6.5, and control the neutralization temperature to ≤30 ℃, add 0.004g of potassium persulfate and 0.04g of azobisisobutylcyanide to obtain the water phase; keep the speed of reaction kettle 1 at 240r / min, and slowly pour the monomer aqueous solution in jacketed reaction kettle 2 into the oil phase jacket In reaction kettle 1, turn on nitrogen emulsification and deoxygenation for 30 minutes, control the system temperature at about 15°C; use a metering pump to add 0.5% sodium bisulfite solution dropwise for polymerization, control the system temperature at 40°C to 50°C, unt...

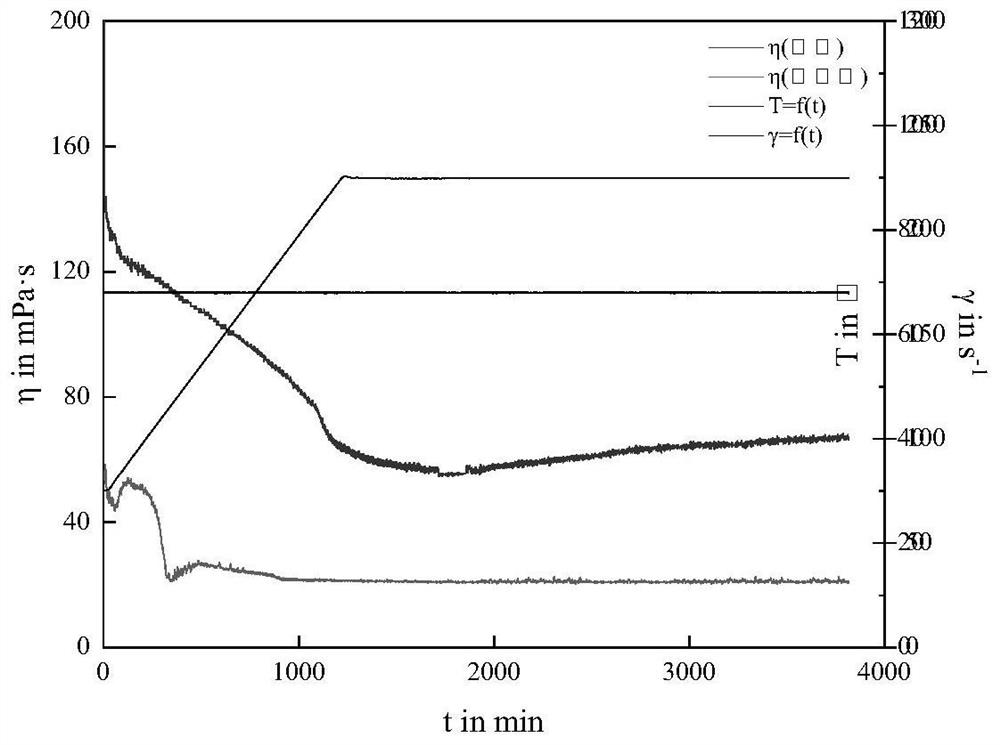

Embodiment 2

[0029] The preparation method of the salt-tolerant structural polymer emulsion provided in this example is: in the jacketed reactor one, add 340g of 3# white oil, 15g of Span 60, 40g of Span 80, and 30g of Tween 80, and start stirring to obtain the oil Phase; add 260g water, 142g acrylamide, 96g acrylic acid, 15g 2-acrylamido-2-methylpropanesulfonic acid, 6g dimethyl diallyl ammonium chloride (DMDAAC), 52g in jacketed reactor two Adjust the pH of the solution to 6.5 with sodium hydroxide, control the neutralization temperature to ≤30°C, add 0.004 g of potassium persulfate and 0.04 g of azobisisobutyrocyanide to obtain the water phase; Slowly pour the monomer aqueous solution in the reaction kettle 2 into the oil-phase jacketed reaction kettle 1, turn on the nitrogen emulsification and deoxygenation for 30 minutes, and control the temperature of the system at about 15°C; use a metering pump to add 0.5% sodium bisulfite solution dropwise for polymerization, Control the temperatu...

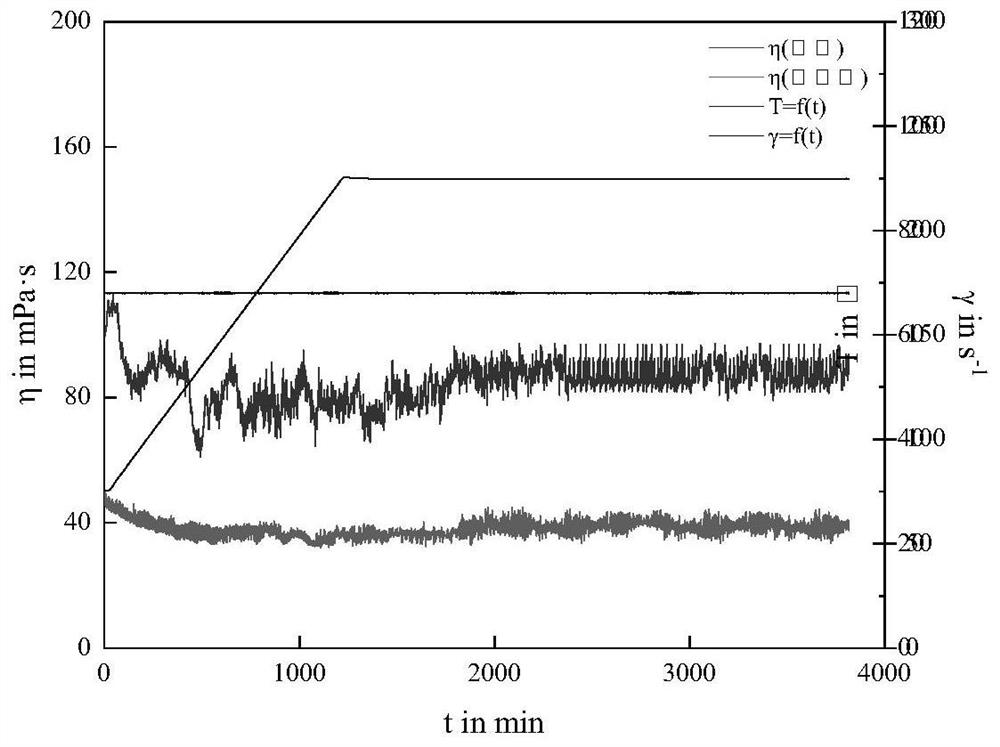

Embodiment 3

[0032]The preparation method of the salt-tolerant structural polymer emulsion provided in this example is: in the jacketed reactor one, add 340g of 3# white oil, 15g of Span 60, 40g of Span 80, and 30g of Tween 80, and start stirring to obtain the oil Phase; Add 260g water, 142g acrylamide, 96g acrylic acid, 15g 2-acrylamido-2-methylpropanesulfonic acid, 10g dodecyl allyl ammonium bromide, 52g sodium hydroxide in jacketed reactor two Adjust the pH of the solution to 6.5, control the neutralization temperature to ≤30°C, add 0.004g of potassium persulfate and 0.04g of azobisisobutyrocyanide to obtain the water phase; keep the speed of reaction kettle 1 at 240r / min, and put the jacketed reaction kettle 2 Slowly pour the aqueous monomer aqueous solution into the oil-phase jacketed reactor 1, turn on the nitrogen emulsification and deoxygenation for 30 minutes, and control the temperature of the system at about 15°C; The temperature is 40℃~50℃, and the reaction is completed until t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com