Preparation method of high-strength and high-modulus polyimide fibers

A polyimide fiber and fiber technology, which is applied in the field of polyimide fiber preparation, can solve the problems of poor mechanical properties of polyimide fiber, difficulty in synergistic control of fiber forming and chemical structure, and high price of specific raw materials. Achieve continuous preparation, good industrialization prospects, and improve rigidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

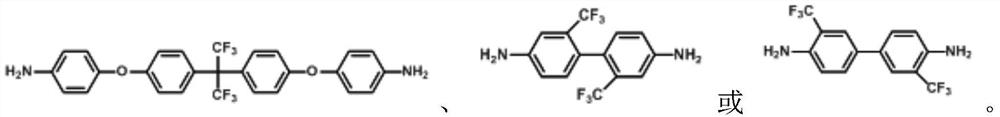

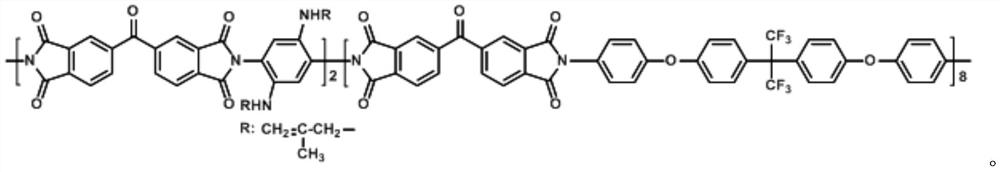

[0037] (1) Under the protection of nitrogen, in a three-necked flask, add 480mL of NMP, 2.76g (0.02mol) of pyromellitic tetramine (Zhengzhou Alpha Chemical, purity 99%), 41.4g (0.08mol) of 2,2 -Bis[4-(4-aminophenoxy)phenyl]hexafluoropropane (Changzhou Sunshine Pharmaceutical, 99.5%) and 32.2g (0.1mol) of BTDA (Beijing Marti Technology), fully stirred and reacted for 12h, control The reaction temperature was 2°C, and a polyamic acid solution was obtained. Subsequently, add 0.05g of pyridine as the cyclization catalyst, stir evenly, respectively raise the temperature to 120°C and 150°C for 1 hour respectively, and finally heat to 200°C and react at a constant temperature for 14 hours to obtain a high viscosity polyimide solution; after cooling, add 4.16g The 3-methyl-4chloro-1-butene, stirred and reacted for 1h to obtain a polyimide solution containing allylamine side group structure, the reaction formula is as follows:

[0038]

[0039] (2) Using the polyimide solution prepared i...

Embodiment 2

[0042] (1) Under the protection of nitrogen, in a three-necked flask, add 480mL of NMP, 4.28g (0.02mol) of Benzenetetramine (Zhengzhou Alpha Chemical, purity 99%), 25.6g (0.08mol) of 4,4 '-Diamino-2,2'-bistrifluoromethylbiphenyl and 32.2g (0.1mol) of BTDA, fully stirred and reacted for 12h, controlled the reaction temperature to 0°C to obtain a polyamic acid solution. Add 0.05g of pyridine as the cyclization catalyst, stir uniformly, then heat up to 120°C and 150°C for 1 hour respectively, and finally heat up to 200°C and react at a constant temperature for 12 hours to obtain a high-viscosity polyimide solution; after cooling, add 4.16g 3-methyl-4chloro-1-butene, stirred and reacted for 30 minutes to obtain a polyimide solution containing allylamine side group structure, the structural formula is as follows:

[0043]

[0044] (2) Take the polyimide solution prepared in step (1) as the spinning slurry, and use a 50-hole spinneret with a diameter of 70 μm, with a diameter of 18 cm ...

Embodiment 3

[0049] (1) According to Example 2, "4,4'-diamino-2,2'-bistrifluoromethylbiphenyl" was changed to "4,4'-diamino-3,3'-bistrifluoro "Methyl biphenyl", the "final temperature rise to 200°C constant temperature reaction for 12h" is changed to "the final temperature rise to 200°C constant temperature reaction for 18h", and the rest are the same as in Example 2, to obtain a polyamide containing an allylamine side group structure The structure of imine solution is as follows:

[0050]

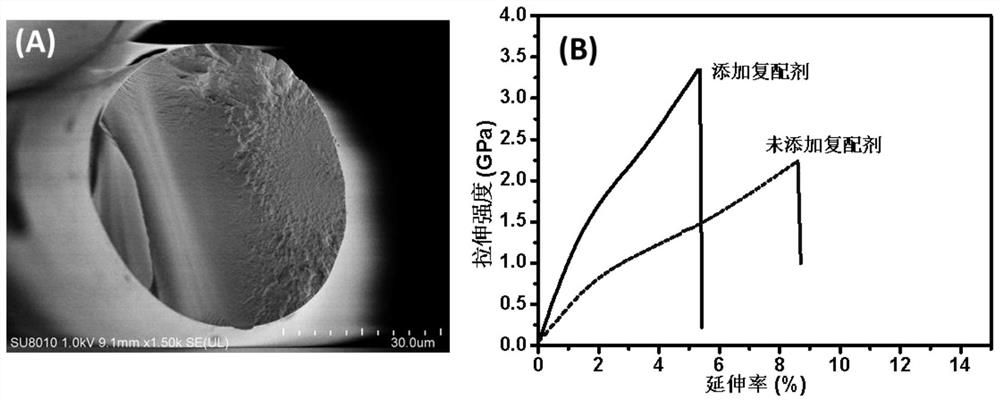

[0051] (2) According to Example 2, except for "the spinning shaft temperature is 370°C, the winding speed is 200m / min, and the obtained nascent fiber is subjected to hot drawing treatment in a 480°C heat pipe, the draft ratio is 3.5 times" , The rest are the same as in Example 2, to obtain a polyimide fiber containing benzibisimidazole, the structural formula is shown below. The resulting polyimide fiber has a density of 1.44g / cm 3 , The tensile strength reaches 3.42GPa, the modulus is 123GPa, and the el...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com