Carbon negative electrode material precursor and preparation method and application thereof, and carbon negative electrode material and preparation method and application thereof

A carbon negative electrode material and precursor technology, applied in the field of lithium-ion batteries, can solve problems such as high thermal expansion coefficient, low porosity, and shortage of raw materials, and achieve the effects of simple preparation process, short process, and reduced production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

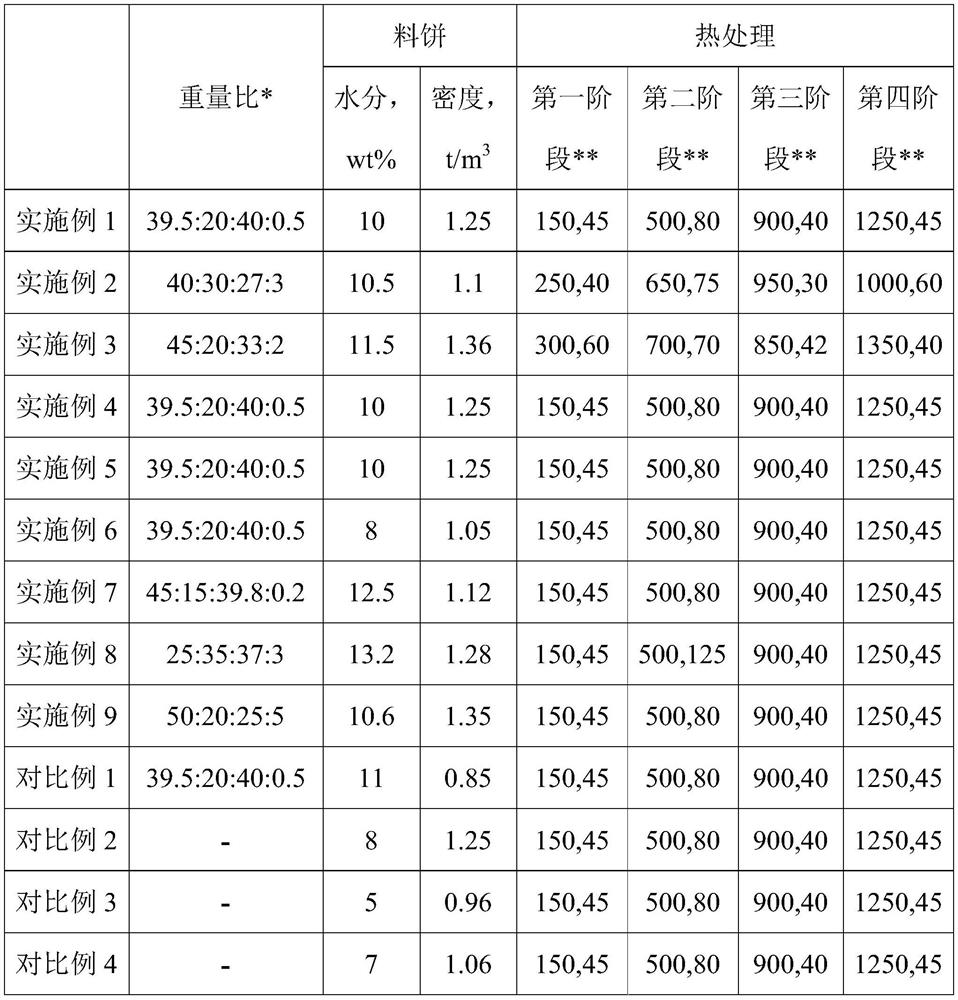

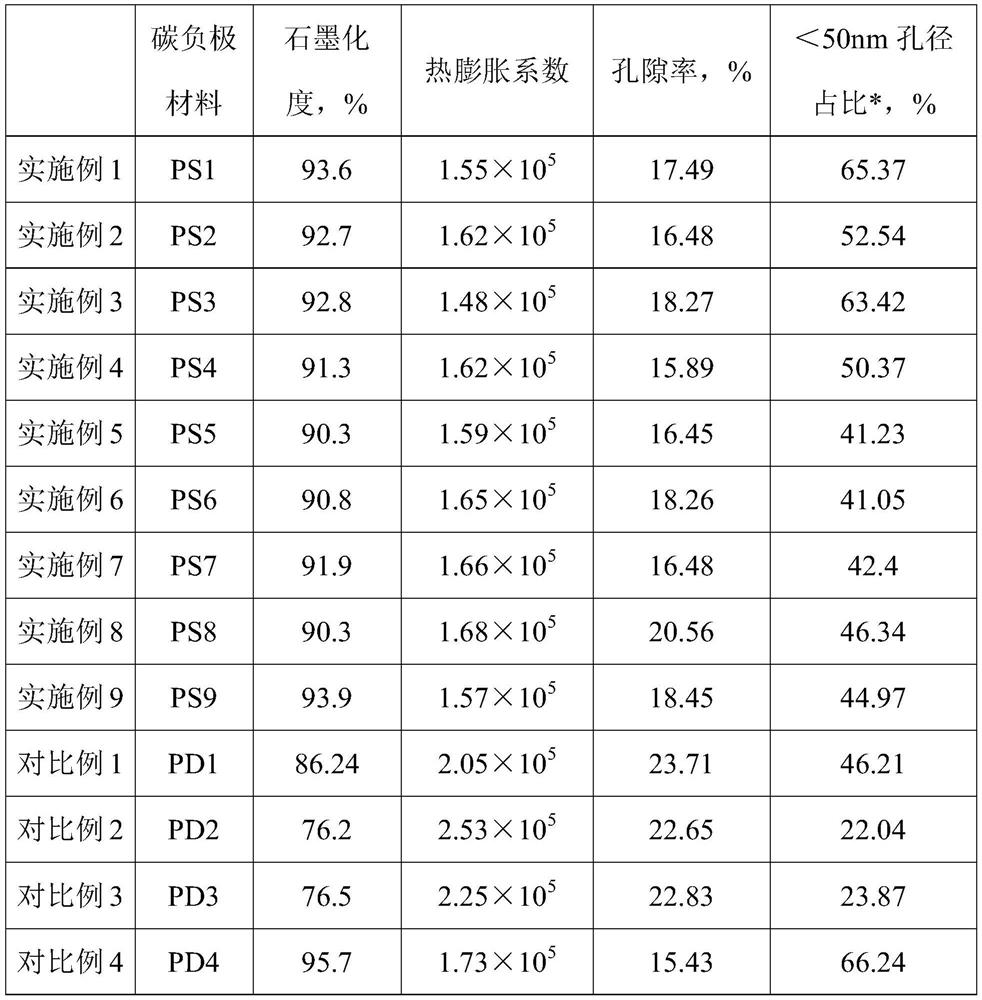

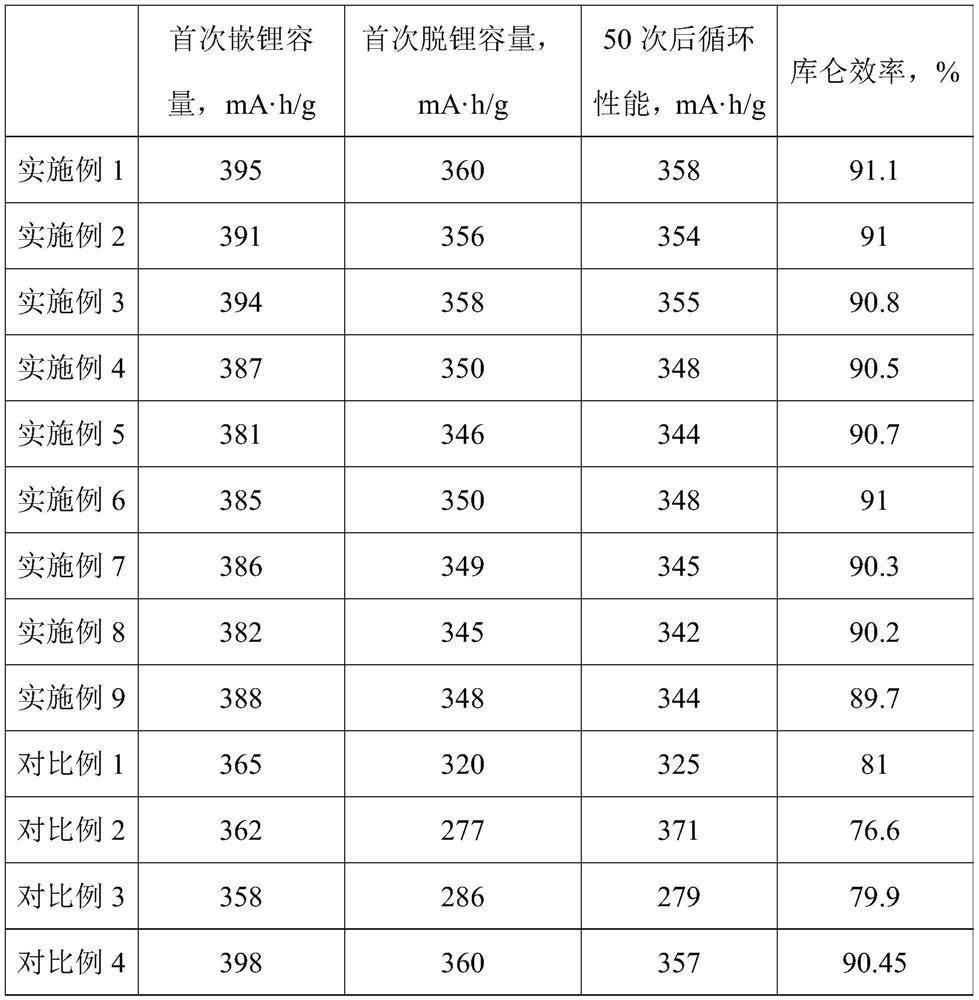

[0024] In a preferred embodiment, the high-rank bituminous coal is high-rank coking coal and lean coal, wherein the weight ratio of high-rank coking coal and lean coal is 20-50:5-15.

[0025] In the present invention, the high-order bituminous coal has a high degree of metamorphism, aromaticity and condensation, and the carbon atomic layer has a certain bonding performance. The carbonization process can gradually become coke, and the pores of the precursor can be improved through the slow carbonization process. The structure is improved.

[0026] In the present invention, unless otherwise specified, the TI refers to the toluene-insoluble components in coal tar pitch and / or other similar products, and the QI refers to the quinoline insoluble matter.

[0027] Preferably, the parameters of the coal-based binder meet: ash content40%, TI content>25wt%, QI content 100°C, moisture content of 5-10wt%; further preferably, the base binder is pitch, preferably selected from coal tar hig...

Embodiment 1

[0068] (1) 95% of the pulverized coal A and coal B are particles with a particle size <1.5mm, 95% are pulverized pitch coke particles with a particle size <1mm, and 90% are pulverized high-temperature pitch particles with a particle size <3mm %, described additive H-1 comprises the graphitization catalyst of 30wt% and the carbon pore modifier of 70wt%, wherein, the weight ratio of aluminosilicate, iron powder and silicon carbide in the graphitization catalyst is 10:5: 85, the weight ratio of potassium nitrate and calcium nitrate in the carbon pore modifier is 80:20;

[0069] (2) Mix and shape the pulverized coal A, coal B, pitch coke and high-temperature pitch with additive H-1 to obtain a cake, wherein the weight ratio of coal A to coal B is 25:14.5;

[0070] (3) Heat treatment, cooling, and sizing of the material cake to obtain a carbon negative electrode material precursor S1, wherein the heat treatment includes a first stage, a second stage, a third stage, and a fourth sta...

Embodiment 2

[0072] (1) 92% of pulverized coal A and coal B with particle size <1.5mm, 95% of pulverized pitch coke with particle size <1mm, and 90% of pulverized high-temperature asphalt with particle size <3mm %, described additive H-2 comprises the graphitization catalyst of 50wt% and the carbon pore modifier of 50wt%, wherein, the weight ratio of aluminosilicate, iron powder and silicon carbide in the graphitization catalyst is 15:5: 80, the weight ratio of potassium nitrate and calcium nitrate in the carbon pore modifier is 90:10;

[0073] (2) Mix and shape the crushed A coal, B coal, pitch coke and high-temperature pitch with additive H-2 to obtain a material cake, wherein the weight ratio of A coal to B coal is 30:10;

[0074] (3) The cake is subjected to heat treatment, cooling, and granulation to obtain a carbon negative electrode material precursor S2, wherein the heat treatment includes a first stage, a second stage, a third stage, and a fourth stage.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

| reflectance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com