Super-hydrophobic coating material as well as preparation method and application thereof

A super-hydrophobic coating and ultrasonic technology, applied in coatings, anti-corrosion coatings, underwater operating equipment, etc., can solve problems such as poor hydrophobicity, high cost of fluorine-containing substances, and adverse environmental impacts, and achieve the goal of coating Good hydrophobic performance, long service life and good protective effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

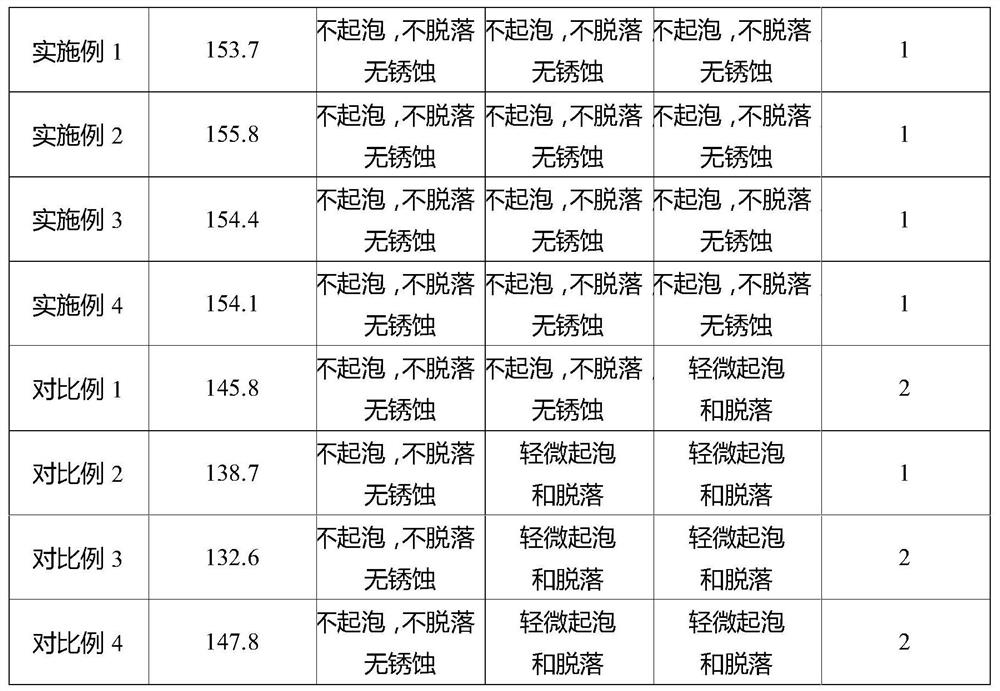

Examples

Embodiment 1

[0023] The preparation step of superhydrophobic coating material comprises the following:

[0024] In the aqueous ethanol solution with a volume ratio of 3:1, add 10 parts of MoS 2 powder, 2 parts nano-Al 2 o 3 and 15 parts of silane coupling agent, first ultrasonic at room temperature for 2 hours, then add an appropriate amount of hydrochloric acid solution, adjust the pH to 4~5, heat, stir rapidly at 70~80°C for 3 hours to fully react, after the reaction is completed, age at room temperature, pump filtered, washed with aqueous ethanol, dried at 80 °C, and ground to obtain modified MoS 2 / Al 2 o 3 Composite particle powder.

[0025] Add 80 parts of polyurethane and 8 parts of terpene resin to 80 parts of ethanol and place in a high-energy ball mill for 4-6 hours to obtain superfine suspension A.

[0026] The above modified MoS 2 / Al 2 o 3 Add the powder and 1.0 parts of polyvinylpyrrolidone to 30 parts of ethanol, heat to 40°C, ultrasonically disperse and stir vigoro...

Embodiment 2

[0030] The preparation step of superhydrophobic coating material comprises the following:

[0031] In the aqueous ethanol solution with a volume ratio of 3:1, add 15 parts of MoS 2 powder, 3 parts nano-Al 2 o 3 and 20 parts of silane coupling agent, first ultrasonic at room temperature for 2 hours, then add an appropriate amount of hydrochloric acid solution, adjust the pH to 4-5, heat, stir rapidly at 70-80°C for 3 hours to fully react, after the reaction is completed, age at room temperature, pump filtered, washed with aqueous ethanol, dried at 80 °C, and ground to obtain modified MoS 2 / Al 2 o 3 Composite particle powder.

[0032] Add 85 parts of polyurethane and 10 parts of terpene resin to 80 parts of ethanol and place in a high-energy ball mill for 4-6 hours to obtain superfine suspension A.

[0033] The above modified MoS 2 / Al 2 o 3 Add the powder and 1.5 parts of polyvinylpyrrolidone to 30 parts of ethanol, heat to 40°C, ultrasonically disperse and stir vigor...

Embodiment 3

[0037] The preparation step of superhydrophobic coating material comprises the following:

[0038] In the aqueous ethanol solution with a volume ratio of 3:1, add 15 parts of MoS 2 powder, 3 parts nano-Al 2 o 3 and 20 parts of silane coupling agent, first ultrasonic at room temperature for 2 hours, then add an appropriate amount of hydrochloric acid solution, adjust the pH to 4-5, heat, stir rapidly at 70-80°C for 3 hours to fully react, after the reaction is completed, age at room temperature, pump filtered, washed with aqueous ethanol, dried at 80 °C, and ground to obtain modified MoS 2 / Al 2 o 3 Composite particle powder.

[0039] Add 95 parts of polyurethane and 10 parts of terpene resin to 80 parts of ethanol and place in a high-energy ball mill for 4-6 hours to obtain superfine suspension A.

[0040] The above modified MoS 2 / Al 2 o 3 Add the powder and 1.5 parts of polyvinylpyrrolidone to 30 parts of ethanol, heat to 40°C, ultrasonically disperse and stir vigor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com