Application of magnetic caramelized carbon nano material in removing heavy metals in water body

A technology of caramelized carbon and nanomaterials, which can be applied in the fields of magnetic field/electric field water/sewage treatment, water pollutants, water/sewage treatment, etc., which can solve problems such as lack of adsorption capacity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

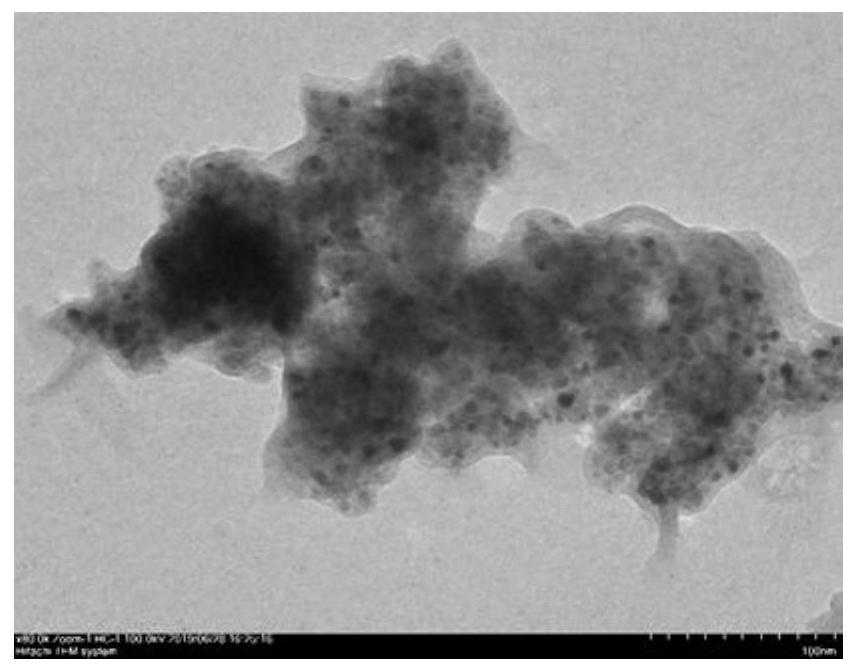

[0042] Synthesis of Magnetic Caramelized Carbon Nanomaterials γ-Fe 2 o 3 @CCM.

[0043] (1) Weigh 79.4mg of ferrous chloride tetrahydrate and 151.4mg of ferric chloride hexahydrate, measure 80mL of ultrapure water into the container, blow nitrogen for 30min to exhaust the air in the device, and add 3mL of ammonia water dropwise under stirring. The obtained magnetic solid particles were collected by magnetic adsorption, washed alternately with high-purity water and ethanol three times, the solids were collected, and dried under vacuum at 60°C to obtain γ-Fe 2 o 3 nanospheres.

[0044] (2) Take 50mg γ-Fe 2 o 3 Nanospheres, 5g of glucose were added to 5mL of ethylene glycol and 90mL of sodium hydroxide aqueous solution (pH = 13) for ultrasonic dispersion for 90min, the mixture was sealed and heated in an oil bath at 190°C, and stirred at a high speed of 1900r / min for 90min , use magnetic adsorption to collect the magnetic solid particles obtained by the reaction, wash them ...

Embodiment 2

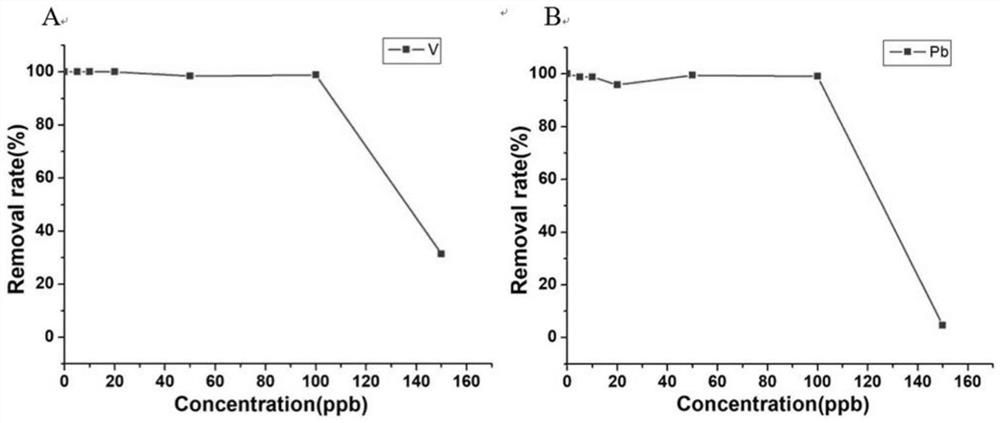

[0049] The same magnetic caramelized carbon nanomaterial as in Example 1 was used to remove lead and vanadium in the water body.

[0050] Magnetic caramelization of carbon nanomaterials γ-Fe 2 o 3 @CCM is used as heavy metal magnetic adsorbent. The magnetic caramelized carbon nanomaterial γ-Fe 2 o 3 Add @CCM to the liquid matrix containing lead and vanadium, adjust the pH to 5-7, ultrasonically disperse the magnetic material in the sample solution, ultrasonically or reciprocally oscillate for 5 minutes, and adsorb and adsorb lead and vanadium, that is, lead in water , Vanadium removal at the same time. Caramelized Carbon Nanomaterials γ-Fe 2 o 3 The addition amount of @CCM is 0.4g / L. Use a concentration of 1% HNO 3 The solution elution shakes for 1-5min, and the metal ions can be eluted into the eluent, realizing the reuse of materials.

[0051] image 3 is the magnetic caramelized carbon nanomaterial γ-Fe 2 o 3 The change diagram of the removal rate of @CCM used t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com