Preparation for removing characteristic pollutants in wastewater in electronic industry as well as preparation method and application thereof

A characteristic pollutant, technology in the electronics industry, used in water pollutants, water/sewage treatment, metallurgical wastewater treatment, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0053] Example 1 Preparation of organically modified montmorillonite loaded nanometer zero-valent iron

[0054] 1. Preparation of Organically Modified Montmorillonite

[0055] The preparation method of organically modified montmorillonite is carried out as follows:

[0056] 1) Weigh 0.2g of cetyltrimethylammonium bromide (CTMB) and dissolve it in 200mL of deionized water and heat it to 60°C in a water bath, then add 5g of sodium ion montmorillonite (Na-MMT, the cation exchange capacity is about 1mmol / g), stirring continuously at 60°C for 30min.

[0057] 2) The suspension was centrifuged, and the precipitate was washed three times with deionized water, and then dried in an oven at 70° C. for 14 hours.

[0058] 3) Take out the dried precipitate, pass it through a 100-mesh sieve after grinding, and activate it at 115° C. for 2 hours to obtain organic montmorillonite (OMt).

[0059] 2. Preparation of organically modified montmorillonite-loaded nano-zero-valent iron materials (...

Embodiment 2

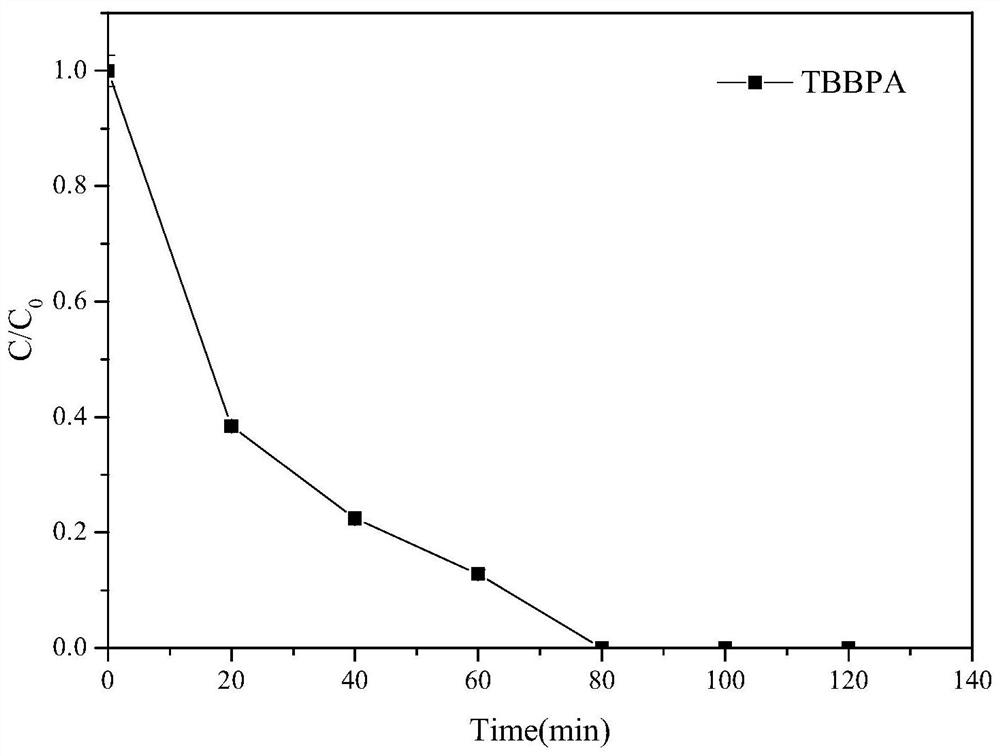

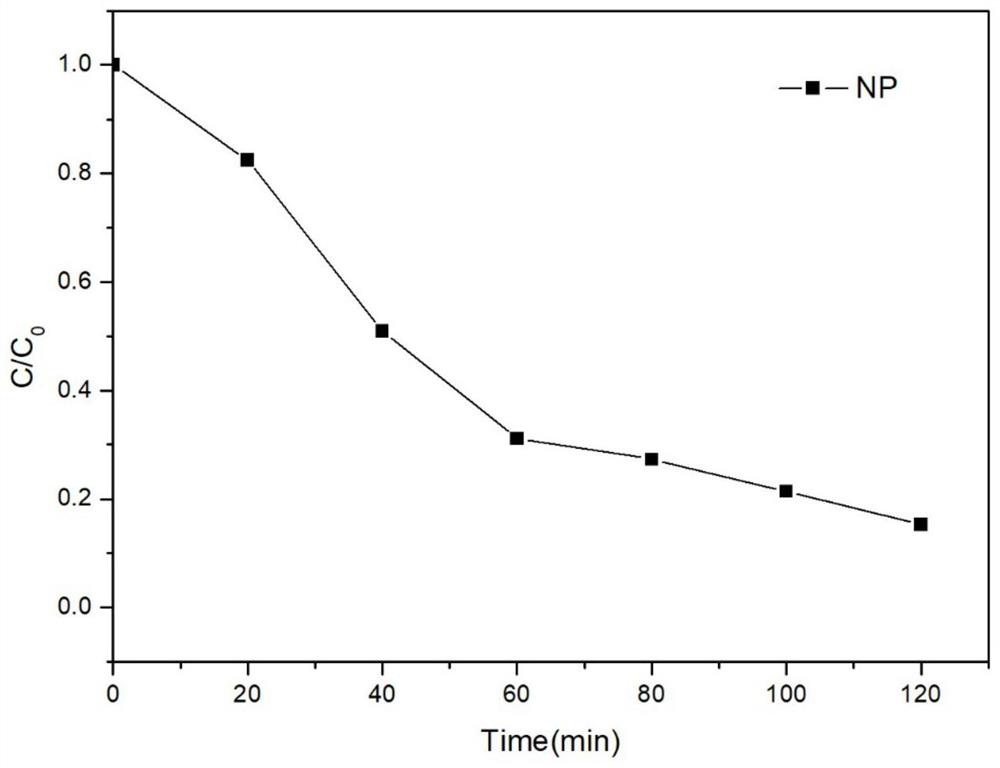

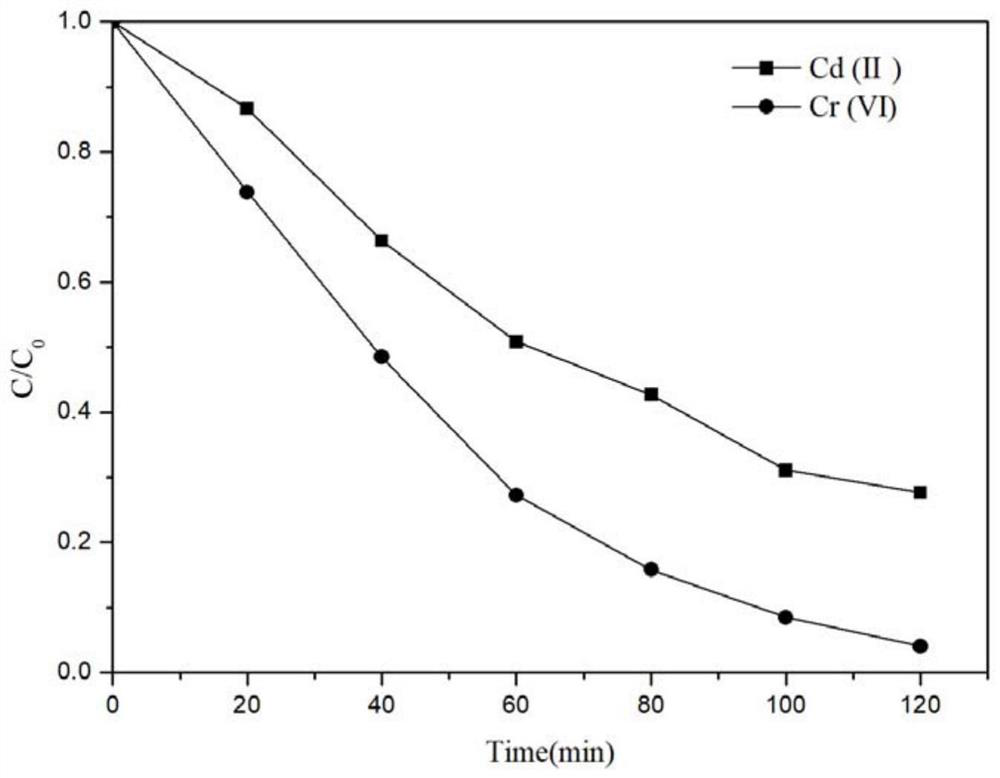

[0064] Example 2 Degradation test of organically modified montmorillonite loaded with nanometer zero-valent iron and microorganisms to remove characteristic pollutants

[0065] In order to simulate the actual situation and explore the combination of organically modified montmorillonite loaded with nanometer zero-valent iron and microorganisms to remove characteristic pollutants, batch experiments were designed. The selected characteristic organic pollutants are TBBPA and nonylphenol, and the selected heavy metals are hexavalent chromium and divalent cadmium.

[0066] 1. Enrichment and domestication of flora

[0067] The biochemical pool activated sludge taken in the urban sewage treatment plant is carried out in the laboratory to domesticate the flora, take out 100mL of activated sludge mud-water mixture in a 500mL Erlenmeyer flask, add 400mL of liquid medium (see the specific composition of liquid medium) Table 1), seal with a gas-permeable sealing film, and cultivate under ...

Embodiment 3

[0074] Example 3 Effect of organically modified montmorillonite loaded with nanometer zero-valent iron on the removal of characteristic organic pollutants in wastewater from the electronics industry

[0075] Using the organically modified montmorillonite in Example 1 to load nanometer zero-valent iron, to 500m 3 / d electronics industry wastewater treatment. In the first stage, organically modified montmorillonite loaded with nanometer zero-valent iron is added to the biochemical pool to degrade the characteristic pollutants in wastewater synergistically with microorganisms in the activated sludge; in the second stage, organic modification is added to the secondary reaction pool The montmorillonite is loaded with nanometer zero-valent iron to strengthen the flocculation and sedimentation of suspended matter.

[0076] The specific process parameters are as follows: the dosage of organically modified montmorillonite loaded nanometer zero-valent iron in the biochemical pool is 90...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com