Solid waste stabilizer, and preparation method and application thereof

A stabilizer and catalyst technology, applied in the field of solid waste stabilizer and its preparation, can solve the problems of high treatment cost, cumbersome process, and increase the difficulty of stabilization treatment, and achieve the effect of avoiding pollution and improving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

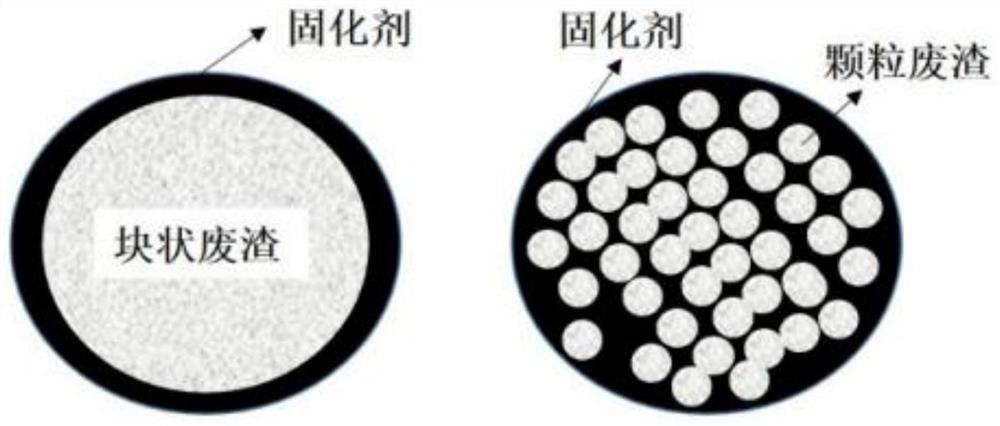

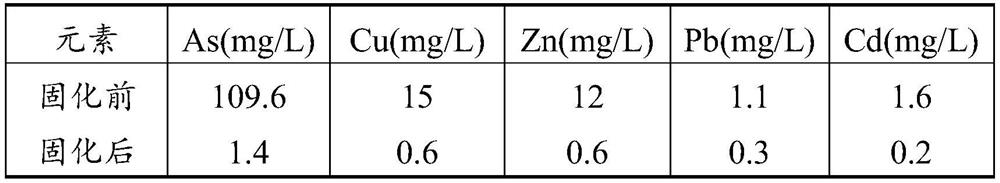

Image

Examples

preparation example Construction

[0029] The present invention also provides a method for preparing the solid waste stabilizer described in the above technical solution, comprising the following steps: mixing polyvinyl alcohol, a silicon source, an organic solvent, a catalyst and water, and performing a polymerization reaction to obtain the solid waste stabilizer.

[0030] The invention mixes polyvinyl alcohol, silicon source, organic solvent, catalyst and water to undergo polymerization reaction to obtain the solid waste stabilizer. In the present invention, the types of the polyvinyl alcohol, the silicon source, and the catalyst are those described in the above technical solution, and will not be repeated here. In the present invention, the organic solvent preferably includes one or more of ethanol, methanol and propanol, and more preferably includes ethanol. The proportioning ratio of the specific substances mentioned above is not particularly limited, and any proportioning ratio can be adopted.

[0031] I...

Embodiment 1

[0049] Mix 5g of polyvinyl alcohol (model PVA2488) and 50mL of water, and stir at 60°C for 1h at a speed of 200r / min to obtain a polyvinyl alcohol solution; mix 15g of tetraethyl orthosilicate, 10mL of water, 20g of ethanol and 0.1 g hydrochloric acid (18wt% hydrochloric acid), and stirred at 60°C for 1 hour at a speed of 200r / min to obtain a silicon prepolymerization solution; Stir for 1 hour under the condition of 200r / min to obtain a solid waste stabilizer.

Embodiment 2

[0051] Mix 7g of polyvinyl alcohol (model PVA2488) and 50mL of water, and stir at 70°C for 0.5h at a speed of 80r / min to obtain a polyvinyl alcohol solution; mix 10g of tetraethyl orthosilicate, 10mL of water, 20g of ethanol and 0.05g of hydrochloric acid (36wt% hydrochloric acid) was mixed and stirred at 60°C for 1h at a speed of 150r / min to obtain a silicon prepolymerization solution; 50mL of polyvinyl alcohol solution and 10mL of silicon prepolymerization solution were mixed, The solid waste stabilizer was obtained by stirring for 0.6 h at a rotational speed of 100 r / min.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com