Chlorohydrination tail gas coupling treatment method

A treatment method, chloroalcoholization technology, applied in gas treatment, chemical instruments and methods, separation methods, etc., can solve problems such as cumbersome operation, high energy consumption, and easy flash explosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

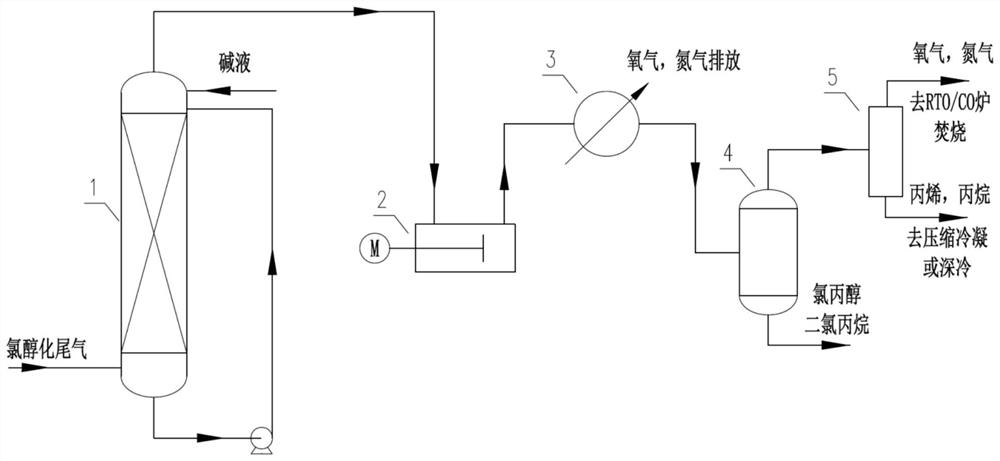

Embodiment 1

[0052] like figure 1 As shown, a chloroalcoholization tail gas coupling treatment system is an alkali washing + compression condensation + membrane separation coupling treatment system, including: an alkali washing tower 1 for removing acid gases in the chlorohydrinization tail gas; a compression cooling device, including a liquid ring Compressor 2, cooler 3 and gas-liquid separator 4 are used to separate relatively high-boiling dichloropropane and chloropropanol from low-boiling nitrogen, oxygen, propane, and propylene; membrane separation device 5 is used for macromolecule Separation of propane, propylene and small molecules of nitrogen and oxygen; cryogenic equipment.

[0053] The bottom of the alkali washing tower 1 is provided with an air inlet, the top is provided with a liquid inlet, the bottom is provided with a liquid outlet, and the top is provided with an air outlet; The liquid port is connected; the top gas outlet of the alkali washing tower 1 is connected to the ...

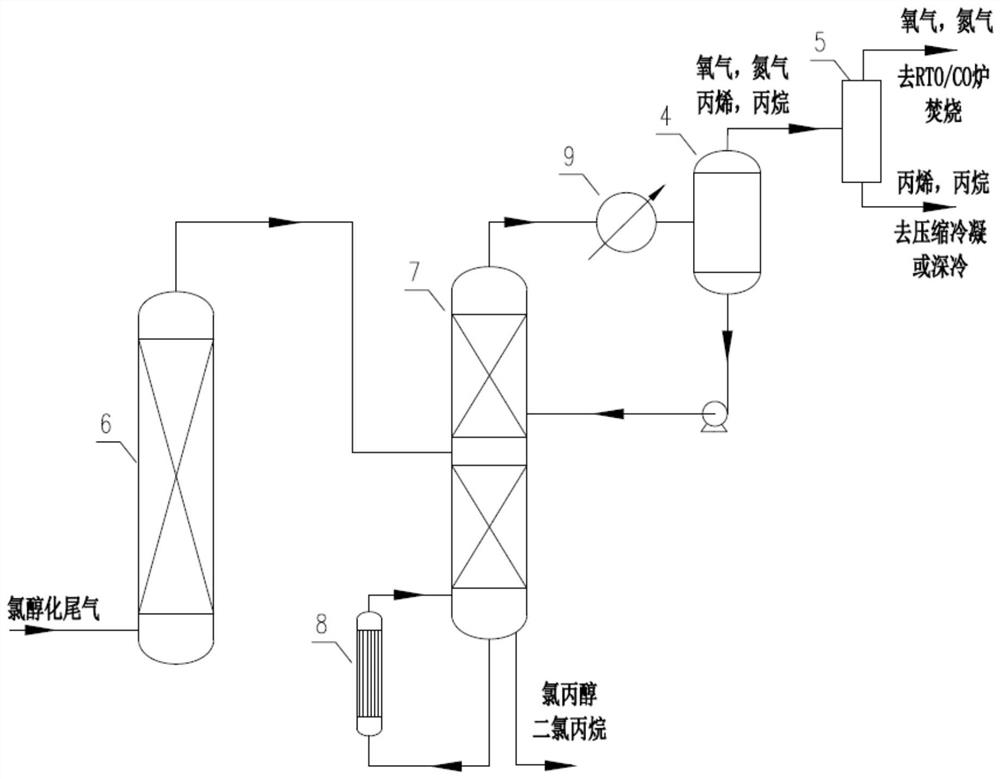

Embodiment 2

[0064] like figure 2 As shown, a chlorohydrinization tail gas coupling treatment system is a solid alkaline substance absorption-pressurized rectification-membrane separation coupling treatment system, including: a solid alkaline substance absorption tower 6, which is used to convert HCl and Cl in the tail gas 2 and water vapor are removed; pressurized rectification tower 7 is used to separate low-boiling propylene, propane, nitrogen, oxygen and high-boiling dichloropropane and chloropropanol in the remaining tail gas; membrane separation device 5 is used for propane, propylene Separation from nitrogen and oxygen; cryogenic equipment.

[0065] The bottom of the solid alkaline absorption tower 6 is provided with an air inlet, and the top is provided with an air outlet, and solid KOH is filled in the solid alkaline absorption tower 6; The inlet of the pressurized rectification tower 7 is connected, the bottom of the pressurized rectification tower 7 is equipped with a reboiler...

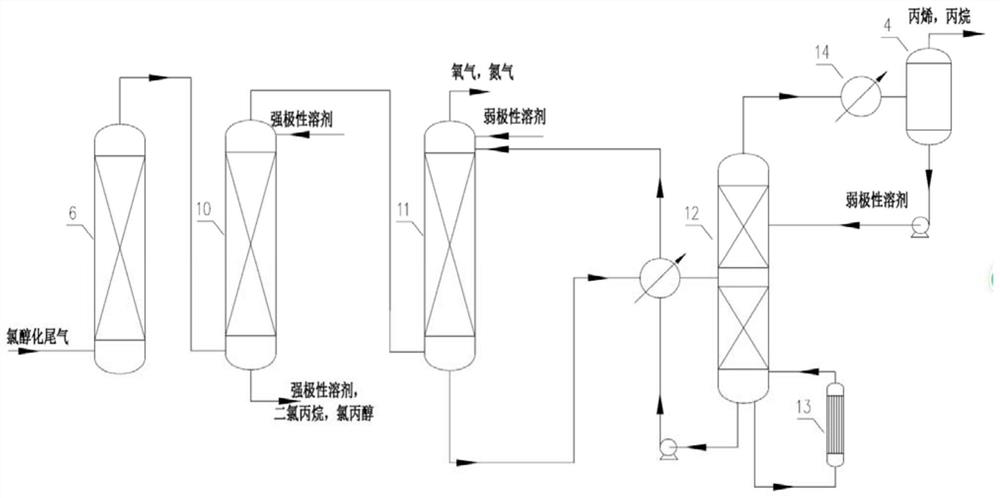

Embodiment 3

[0076] like image 3 As shown, a chlorohydrinization tail gas coupling treatment system system is a solid alkaline substance absorption-strong polar solvent absorption-weak polar solvent absorption coupling treatment system, including: a solid alkaline substance absorption tower 6 for removing the exhaust gas HCl, Cl 2 and water vapor; the first solvent absorption tower 10 is used to separate non-polar propylene, propane, nitrogen, oxygen and highly polar dichloropropane and chloropropanol; the second solvent absorption tower 11 is used to separate propylene, propane With nitrogen, oxygen; regeneration tower 12, used for weak polar solvent circulation regeneration.

[0077] The bottom of the solid alkaline substance absorption tower 6 is provided with an air inlet, and the top is provided with an air outlet, and solid NaOH is filled in the solid alkaline substance absorption tower 6; the gas outlet at the top of the solid alkaline substance absorption tower 6 is connected to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com