Modified red mud porous ceramic, preparation method and application thereof

A porous ceramic and modified technology, applied in the field of ceramics, can solve the problems of difficult recycling, poisoning and deactivation of catalysts, harming the natural environment, etc., and achieve the effects of avoiding deformation and breaking, good contact adsorption, and high apparent porosity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

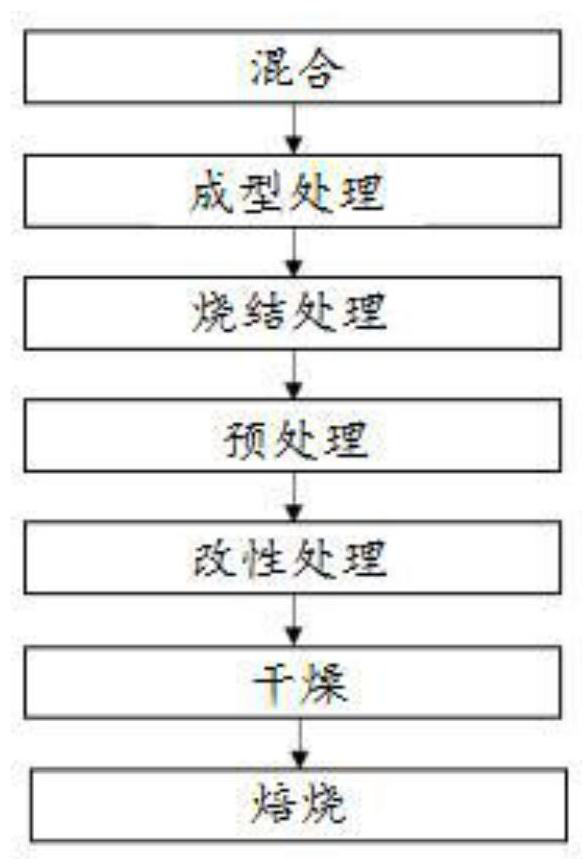

[0026] The present invention also provides a method for preparing the modified red mud porous ceramic described in the above technical solution, comprising the following steps:

[0027] (1) The mixture comprising red mud, fly ash, pore forming agent, foam stabilizer and water is sequentially subjected to molding treatment and sintering treatment to obtain a ceramsite blank;

[0028] (2) performing pretreatment and modification treatment on the ceramsite blank in turn to obtain a modified ceramsite precursor;

[0029] (3) The modified ceramsite precursor is dried and then fired to obtain a modified red mud porous ceramic.

[0030] In the present invention, unless otherwise specified, all the preparation raw materials are commercially available products well known to those skilled in the art.

[0031] In the invention, the mixture including red mud, fly ash, pore forming agent, foam stabilizer and water is sequentially subjected to molding treatment and sintering treatment to o...

Embodiment 1

[0052] according to figure 1 The flow chart shown is for the preparation of modified red mud porous ceramics:

[0053] According to red mud and fly ash total amount 61wt.% (red mud and fly ash mass ratio are 4: 1), stearic acid 20wt.%, borax 4wt.%, water 15wt.% ratio relation, red mud , fly ash, stearic acid, borax and water are mixed and then pelletized to obtain a spherical mixed body.

[0054] Dry the sphere mixed body in a blast drying oven at 100°C for 2 hours, sieve out the sphere mixed body with a particle size of 4-8 mm, and then sinter at 1150°C for 30 minutes to obtain a ceramsite green body .

[0055] Soak the ceramsite blank in 1mol / L hydrochloric acid solution for 24 hours, rinse it repeatedly with deionized water until it becomes neutral, and dry it in a drying oven at 100°C for 2 hours to obtain the ball blank to be modified.

[0056] Take 100mL of 0.1mol / L lanthanum nitrate solution and place it in a 250mL Erlenmeyer flask, add 20g of ball billet to be modif...

Embodiment 2

[0059] According to red mud and fly ash mass ratio is 9:1, stearic acid 20wt.%, borax 4w.t%, water 15wt.% ratio relation, red mud, fly ash, stearic acid, borax and water After mixing, it is pelletized to obtain a sphere-mixed green body.

[0060] Dry the sphere mixed body in a blast drying oven at 100°C for 2 hours, sieve out the sphere mixed body with a particle size of 4-8 mm, and then sinter at 1150°C for 30 minutes to obtain a ceramsite green body .

[0061] Soak the ceramsite blank in 1mol / L hydrochloric acid solution for 24 hours, rinse it repeatedly with deionized water until it becomes neutral, and dry it in a drying oven at 100°C for 2 hours to obtain the ball blank to be modified.

[0062] Take 100mL of 0.1mol / L lanthanum nitrate solution and place it in a 250mL Erlenmeyer flask, add 20g of ball billet to be modified, and soak at 45°C for 12h to obtain the modified ceramsite precursor. During the soaking process, the Erlenmeyer flask should be The rubber stopper is...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com