Iridium metal complex luminescent material and preparation and application thereof

A technology of iridium metal complex and luminescent material, applied in the field of iridium metal complex luminescent material, can solve the problems of insufficient luminous efficiency and lifespan, and achieve the effects of improved luminous efficiency, high yield and high product purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

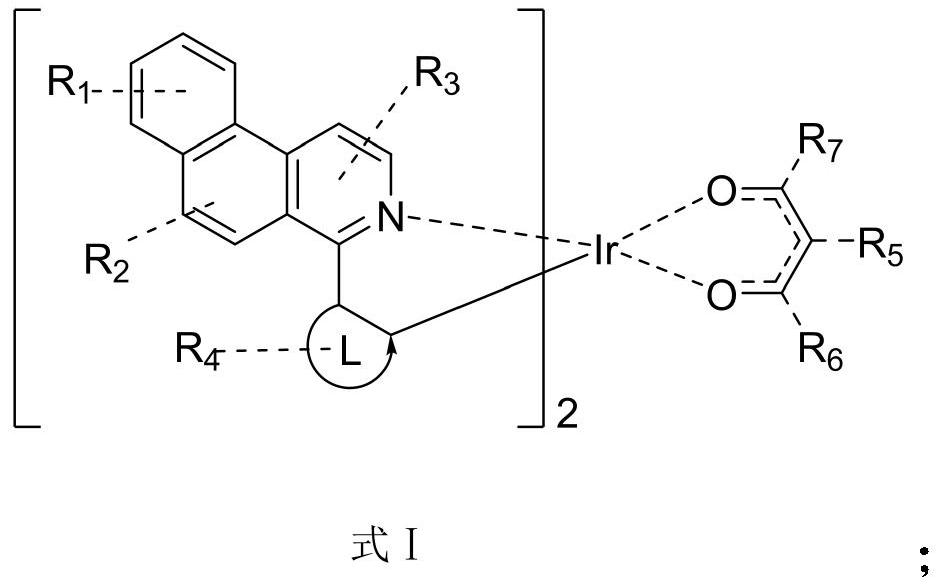

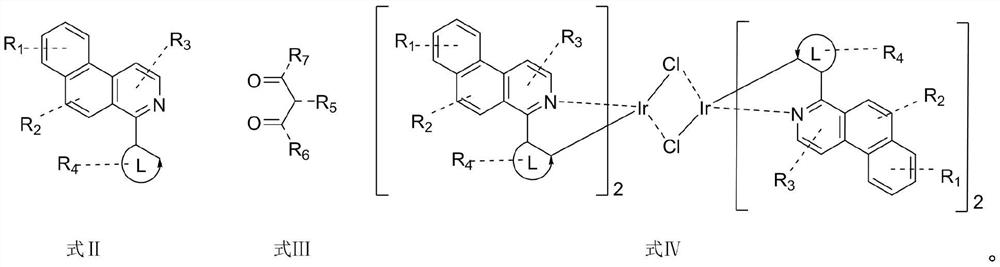

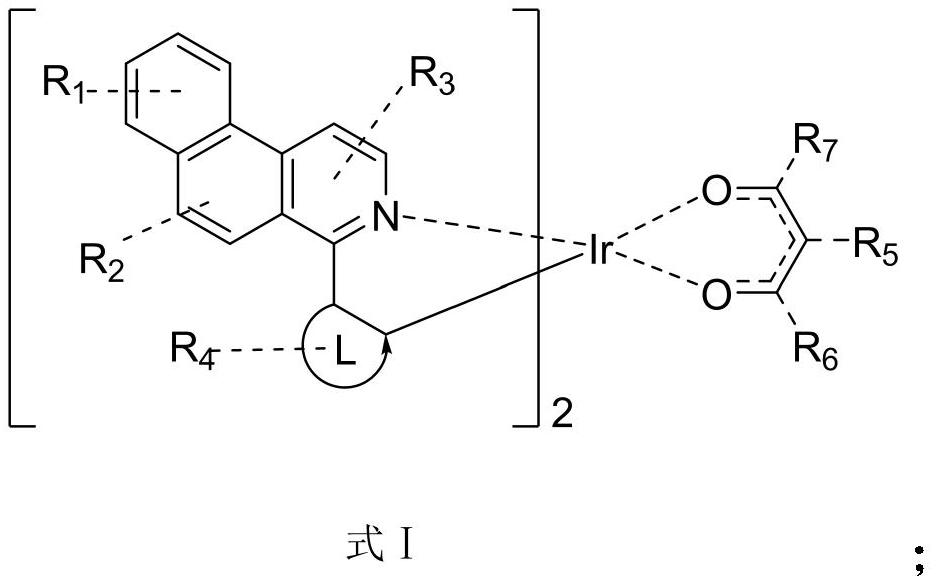

[0060] The invention also discloses a preparation method of an iridium metal complex luminescent material, comprising the following steps:

[0061] (1) Under the protection of an inert gas, add solvent A to the mixture of the compound of the following general formula II and iridium trichloride, set the temperature at 115-125°C, react for 24-30h, cool, filter, and wash and dry the precipitate Dry, obtain following general formula IV compound;

[0062] Wherein, the molar ratio of the compound of general formula II to iridium trichloride is (2.2-2.8): 1;

[0063] (2) Add alkali and solvent B to the compound of general formula IV in sequence, and after inert gas replacement three times, add the following compound of general formula III under the protection of inert gas, set the temperature at 115-125°C, react for 10-30 hours, and cool The precipitate is precipitated, and then the precipitate is chromatographed to obtain the compound of formula I;

[0064] Wherein, the molar rati...

Embodiment 1

[0075] A kind of preparation of iridium metal complex luminescent material (formula I-1), its specific synthetic steps are as follows:

[0076] The synthetic route is:

[0077]

[0078] Step (1): Under nitrogen protection system, weigh ligand II-1 (12.76g, 50mmol), IrC1 3 ·3H 2 O (7.05g, 20mmol) was put into the reaction system, a mixed solution of 300m1 ethylene glycol ether and 100m1 pure water was added, refluxed for 25 hours under the protection of nitrogen, and then cooled to room temperature, a precipitate was precipitated, the precipitate was suction filtered, water, Anhydrous ethanol and petroleum ether were washed and dried in sequence. The mass of bridging ligand IV-1 obtained as a dark red powder was 8.24 g, and the yield was 56%.

[0079] Step (2): Weigh the bridging ligand IV-1 (7.36g, 5mmol) in the step (1), add anhydrous potassium carbonate (6.9g, 50mmol), and then add 100ml ethylene glycol ether to the system, Replace nitrogen three times, add general fo...

Embodiment 2

[0085] A kind of preparation of iridium metal complex luminescent material (formula I-31), its specific synthetic steps are as follows:

[0086] The synthetic route is:

[0087]

[0088] Step (1): Under nitrogen protection system, weigh ligand II-31 (13.57g, 44mmol), IrC1 3 ·3H 2 O (7.05g, 20mmol) was put into the reaction system, a mixed solution of 330m1 ethylene glycol ether and 110m1 pure water was added, refluxed for 30 hours under nitrogen protection, and then cooled to room temperature, a precipitate was precipitated, the precipitate was suction filtered, water, Anhydrous ethanol and petroleum ether were washed and dried in sequence. The weight of bridging ligand IV-31 obtained as dark red powder was 10.78 g, and the yield was 64%.

[0089] Step (2): Weigh the bridging ligand IV-31 (10.11g, 6mmol) in step (1), add anhydrous potassium carbonate (8.28g, 60mmol), and then add 130ml of ethylene glycol ether to the system, The nitrogen was replaced three times, and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com