Microwave preparation method of etimicin sulfate

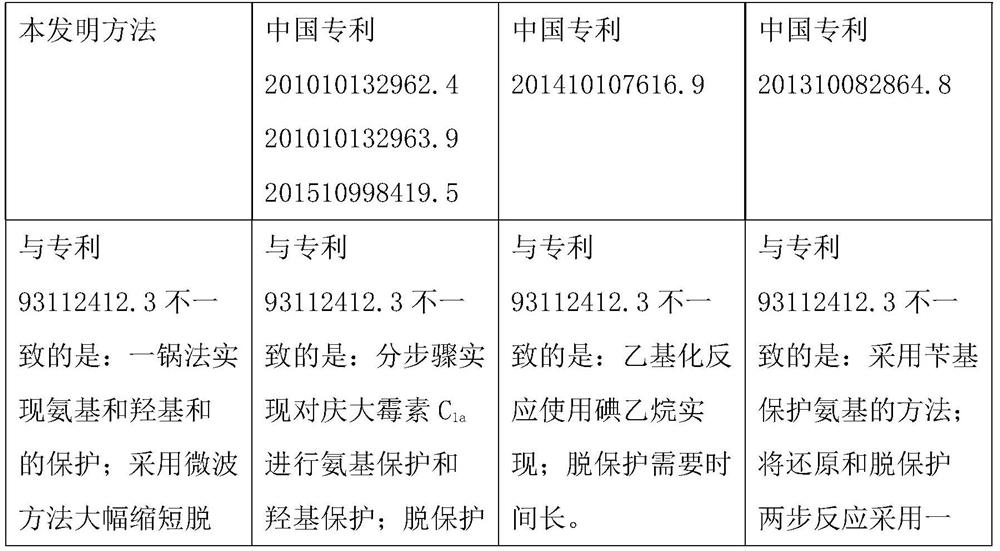

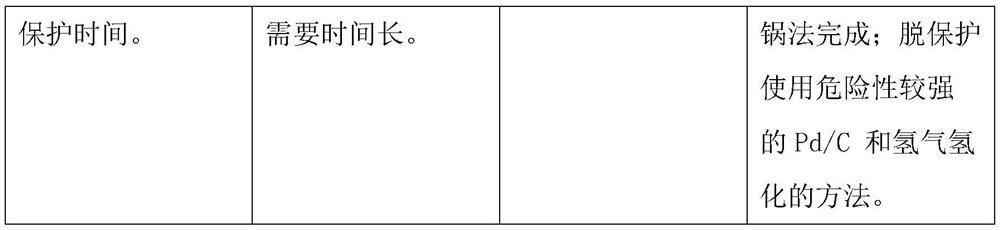

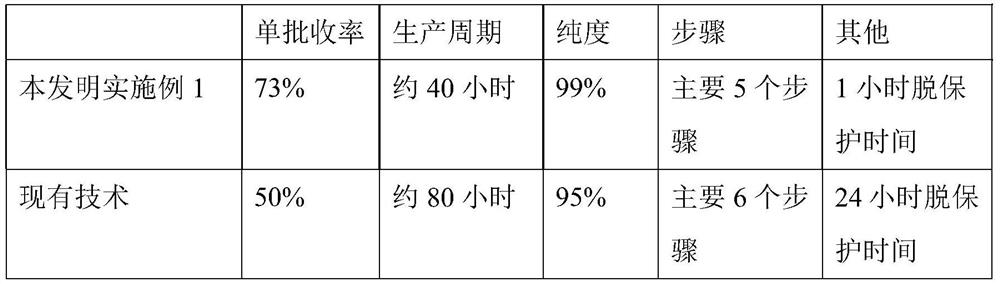

A technology of etimicin sulfate and sulfuric acid, which is applied in the preparation of sugar derivatives, chemical instruments and methods, sugar derivatives, etc., can solve the problems of not effectively protecting hydroxyl groups and reducing by-products.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0047] At room temperature, add 30L of methanol, 4.50kg of gentamicin sulfate C into the microwave reactor 1a , 0.8L sulfuric acid, 3.2kg anhydrous zinc acetate, stirring to dissolve. Add dropwise 3.5 L of acetic anhydride for acetylation. Microwave irradiation was performed for 13 minutes. The resulting reaction solution is dezincified, then injected into a 732 strong acidic cation exchange resin column, washed with water until the optical rotation is zero, and then analyzed with ammonia water with a concentration of 0.15-1mol / L to obtain the analytical solution of the desired product, and decompressed Concentration afforded a pale yellow oil. Add 20L of tetrahydrofuran to the reaction kettle of the obtained oil, and adjust the pH to 1 with sulfuric acid; add 40ml of acetaldehyde dropwise at 15°C; stir for 30 minutes, then add 400g of sodium borohydride, return to room temperature and stir for 60 minutes. The solvent was evaporated, an aqueous sodium hydroxide solution was...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com