Solvent-free three-component polyurethane adhesive and preparation method thereof

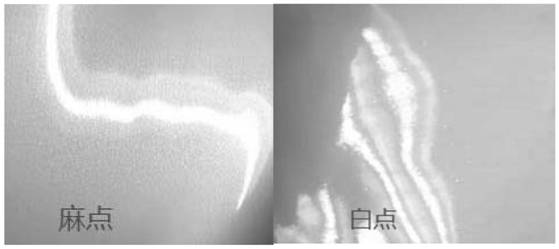

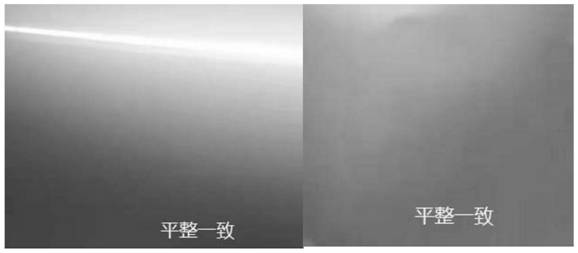

A polyurethane adhesive, three-component technology, applied in polyurea/polyurethane adhesives, adhesive types, adhesive additives, etc., can solve poor wettability, poor product surface smoothness, pitting or White spots etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0038] As mentioned above, in the first aspect, the present invention provides a method for preparing a solvent-free three-component polyurethane adhesive, the preparation method comprising the following steps:

[0039] (1) Preparation of component A:

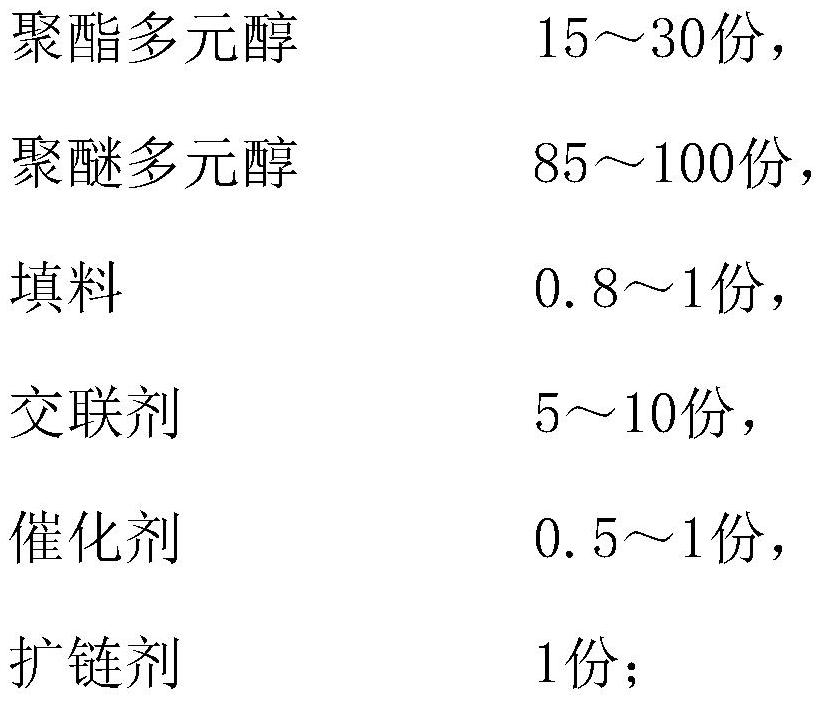

[0040] (1.1) Material preparation: Weigh raw materials according to the following parts by mass

[0041]

[0042] (1.2) Preparation of component A: raise the temperature of the reactor to 40-85°C, add polyether polyol, start stirring, then add polyester polyol, crosslinking agent, catalyst, filler and chain extender, and continue stirring until Evenly, then vacuum dehydrate until the water content is <0.05%, and finally cool, seal and store to obtain component A;

[0043] (2) Preparation of component B:

[0044] (2.1) Material preparation: Weigh raw materials according to the following parts by mass

[0045] 90-100 parts of isocyanate,

[0046] 100-110 parts of polyester polyol,

[0047] Catalyst 0.7~1 part;

[0048] (...

Embodiment 1

[0061] This example is used to illustrate the preparation method of a solvent-free three-component polyurethane adhesive according to the present invention. The preparation method includes the following steps:

[0062] (1) Preparation of component A:

[0063] The temperature of the reactor was raised to 40-85°C, 60 parts by mass of polypropylene glycol and 25 parts by mass of epoxy soybean oil modified polyol were added, stirring was started, and then 30 parts by mass of castor oil and 5 parts by mass of xylose were added Alcohol, 0.5 parts by mass of dibutyltin dilaurate, 1 part by mass of calcium carbonate and 1 part by mass of 2,6-diethylaniline, continue to stir until uniform, then vacuum dehydrate until the water content <0.05%, and finally cool , sealed and preserved to obtain component A;

[0064] (2) Preparation of component B:

[0065] Add 90 parts by mass of dicyclohexyl diisocyanate and 110 parts by mass of castor oil into the reactor, stir evenly at room temperat...

Embodiment 2

[0070] This example is used to illustrate the preparation method of a solvent-free three-component polyurethane adhesive according to the present invention. The preparation method includes the following steps:

[0071] (1) Preparation of component A:

[0072] Raise the temperature of the reactor to 40-85°C, add 50 parts by mass of low molecular weight liquid polyethylene glycol and 50 parts by mass of polytetrahydrofuran glycol, start stirring, then add 15 parts by mass of castor oil, 8 parts by mass of sorbic acid Sugar alcohol, 0.7 mass parts of stannous octoate, 1 mass part of calcium carbonate and 1 mass part of 1,4-butanediol, continue to stir until uniform, then vacuum dehydrate until the water content <0.05%, finally cool and seal Save to get component A;

[0073] (2) Preparation of component B:

[0074] Add 95 parts by mass of toluene diisocyanate and castor oil of 105 parts by mass in the reactor, stir evenly at room temperature, then vacuumize and dehydrate, then a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com