NixSiy/Ga2O3 Schottky diode compatible with Si process and preparation method of NixSiy/Ga2O3 Schottky diode

A Schottky diode and process technology, which is applied in semiconductor/solid-state device manufacturing, electrical components, circuits, etc., can solve the problems of small adjustable range of barrier height, high barrier height, and high conduction voltage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

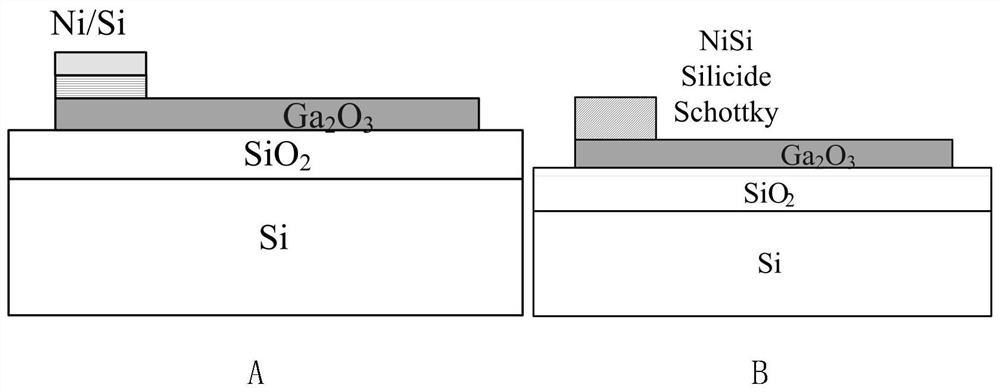

[0036] A Ni that is compatible with the Si process x Si y / Ga 2 o 3 Schottky diode manufacturing method, comprising the following steps:

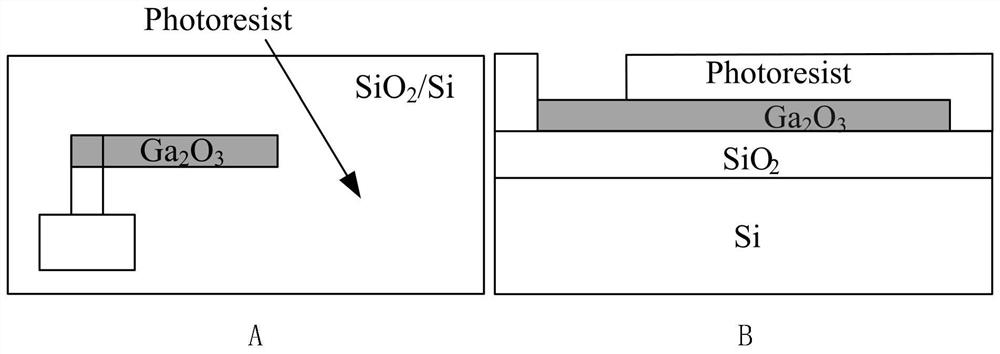

[0037] Step one, the Ga 2 o 3 The film is covered on the working surface of the marking sheet, and the working surface is completely coated with glue.

[0038] In this embodiment, the specific operation of step 1 is as follows:

[0039] Choose SiO2 2 / Si double-layer marking sheet is used as the marking sheet of this embodiment, and its SiO 2 The surface serves as a working surface having first and second regions adjoining each other and a third region adjoining and cooperating with the first region.

[0040] Will be from Ga 2 o 3 The area torn off from the single crystal is 3×20μm 2 Ga 2 o 3 Film mechanically transferred to an area of 1 × 1 cm 2 SiO 2 SiO / Si double-layer marker sheet 2 surface, with SiO 2 / Si bilayer marker sheet as Ga 2 o 3 For the supporting body of the film, apply glue evenly on the working surface,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com