High-efficiency catalyst for growing carbon nanotubes, and preparation method and use method thereof

A carbon nanotube and catalyst technology, applied in the field of high-efficiency catalysts and preparation thereof, can solve the problems of high preparation cost, easy deactivation, low yield and the like of high-quality carbon nanotubes, and achieves a simple and easy preparation process and low cost of raw materials Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0028] The present invention is a method for preparing a highly efficient catalyst for growing carbon nanotubes, the catalyst formula comprising:

[0029] 1.5-2.5 parts of cobalt,

[0030] 0.25 to 1 part of iron,

[0031] 0.5-1.5 parts of alumina,

[0032] Dysprosium of 0.05~0.15 parts,

[0033] 0.05-0.15 parts of molybdenum oxide.

[0034] Described high-efficiency catalyst preparation method is carried out as follows:

[0035] S1. Weigh the above-mentioned metal / metal oxide precursor raw materials in molar ratio, and disperse them in deionized water;

[0036] S2. Add complexing agent or alkaline solution to S1 by complexation method or co-precipitation method, fully stir and reflux for 12 hours to make all components evenly mixed;

[0037] S3. If S2 adopts the complexation method, dry the mixed solution slowly at 60-150°C. If S2 adopts the co-precipitation method, age the mixed precipitate at 60-150°C for 12-24 hours, and then wash it repeatedly with water after suction...

Embodiment 1

[0049] Example 1: Experiment of a blank control group without doping rare earth elements.

[0050]s1) Preparation of cobalt-iron-based catalyst: Weigh 2 parts of cobalt nitrate, 0.25 parts of iron nitrate, 1 part of aluminum nitrate, and 0.05 part of ammonium molybdate into deionized water and stir for 30 minutes, then add excess sodium hydroxide solution , stirred and refluxed at 100°C for 12h, aged at 90°C for 12h, and the resulting precipitate was repeatedly washed with water and then dried. The dried product was packed in a quartz boat, first placed in a horizontal tube furnace for calcination at 500°C in air for two hours, and then reduced with hydrogen for 10 minutes under the protection of argon to finally obtain a cobalt-iron-based catalyst.

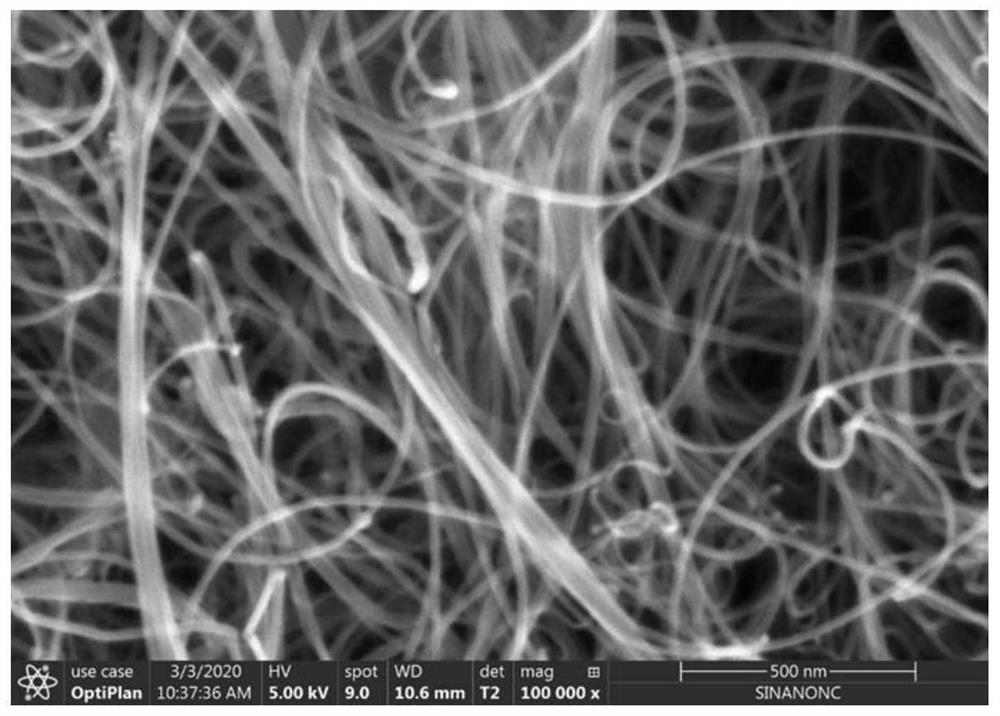

[0051] s2) Preparation of carbon nanotubes: Weigh 0.1 g of the above-mentioned cobalt-iron-based catalyst and put it in a quartz boat, place it in a horizontal tube furnace, and fill it with argon gas at a standard atmospheric pr...

Embodiment 2

[0052] Example 2: Routine experiments on dysprosium doped catalysts.

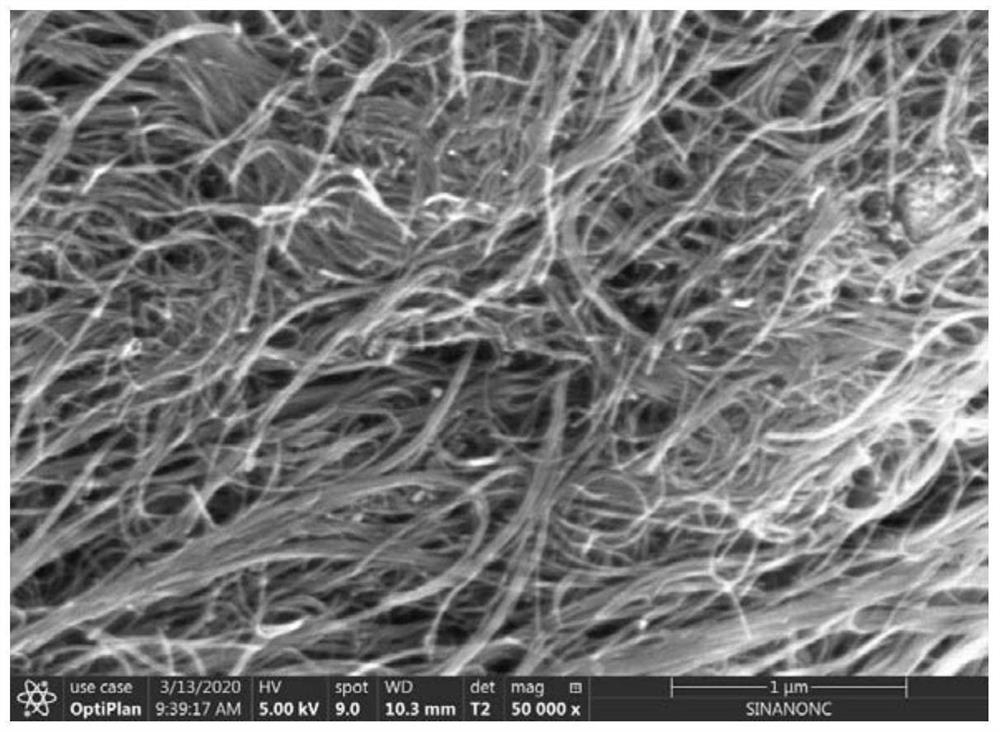

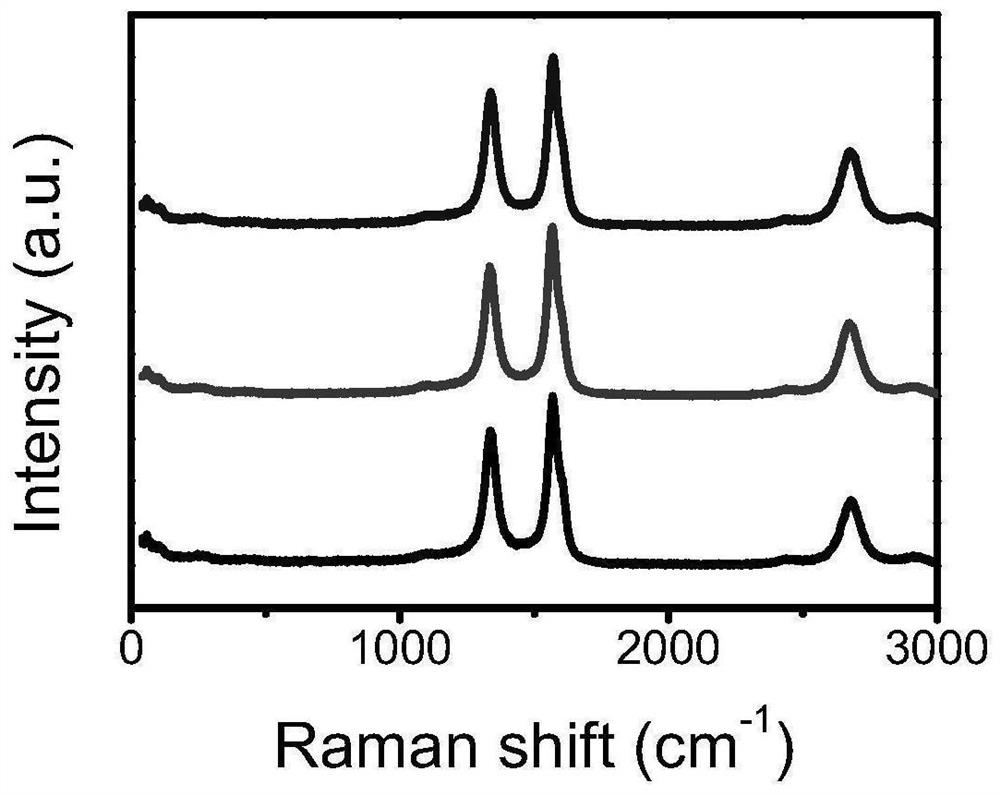

[0053] 0.05 part of dysprosium nitrate is added to the raw material in step s1, and the others are the same as above to obtain a dysprosium-doped cobalt-iron-based catalyst. The s2 step is the same as above, and the prepared carbon nanotube scanning characterization is as follows figure 2 As shown, the Raman characterization is as image 3 shown.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com