Preparation method and application of N-heterocyclic carbene modified nickel-iridium diatomic carbon-based catalyst

A technology of nitrogen-heterocyclic carbene and carbon-based catalysts, applied in chemical instruments and methods, physical/chemical process catalysts, organic compound/hydride/coordination complex catalysts, etc., can solve problems such as lack, and achieve a well-developed porous structure , improve product selectivity and conversion efficiency, and broad application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

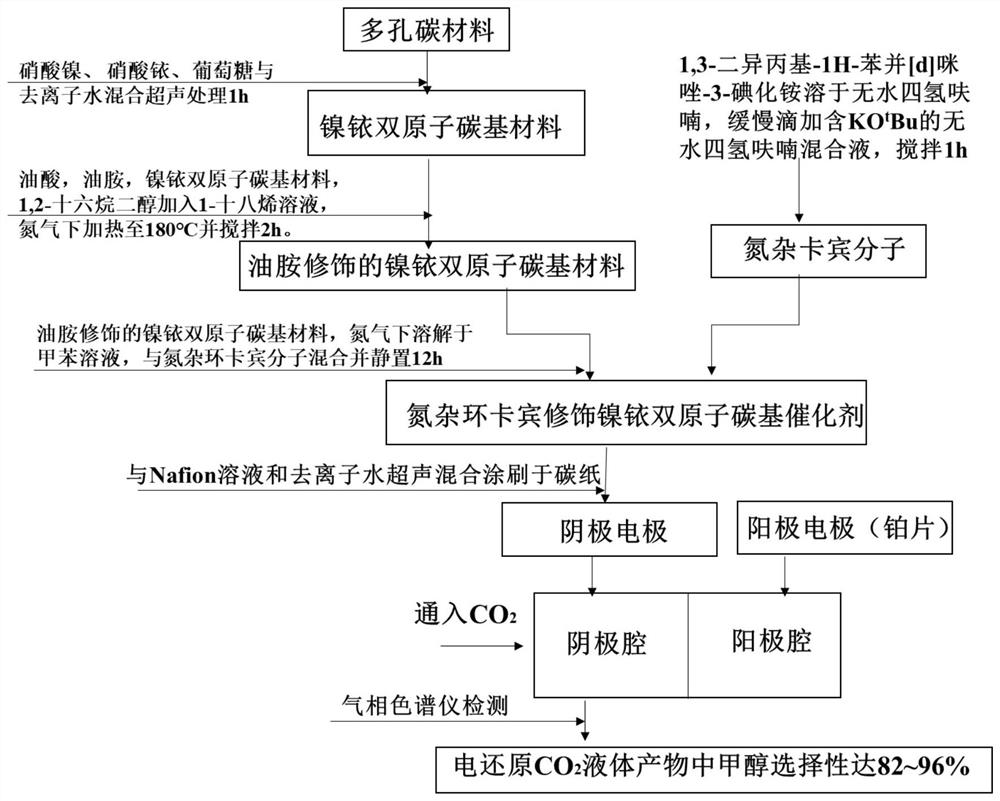

[0031] Such as figure 1 Shown, provide a kind of preparation method of nitrogen-heterocyclic carbene modified nickel-iridium diatomic carbon-based catalyst, specifically comprise the steps:

[0032] (1) Take 5g of sodium citrate and 5g of potassium citrate and mix them evenly, place them in an electric heating tube furnace and feed in argon gas, start the electric heating furnace and control the heating rate to 10°C min -1 , heated to 800°C and then pyrolyzed at constant temperature for 2h. The pyrolysis product was treated with 0.5M H 2 SO 4 The solution and deionized water were washed three times by centrifugation, and then dried in a vacuum oven at 60°C to obtain a porous carbon material.

[0033] (2) Take 0.8g of the porous carbon material in step (1), 3mmol of nickel nitrate, 3mmol of iridium nitrate, 67mmol of glucose and 50mL of deionized water, mix and sonicate for 1h, then centrifuge (8000rpm) and dry at 80°C for 12h to obtain a solid product .

[0034](3) Mix th...

Embodiment 1

[0045] Take 5g of sodium citrate and 5g of potassium citrate and mix them evenly, place them in an electric heating tube furnace and feed in argon gas, start the electric heating furnace and control the heating rate to 10°C min -1 , heated to 800°C and then pyrolyzed at constant temperature for 2h. The pyrolysis product was treated with 0.5M H 2 SO 4 The solution and deionized water were washed three times by centrifugation, and then dried in a vacuum oven at 60°C to obtain a porous carbon material. Take 0.8g of porous carbon material, 3mmol of nickel nitrate, 3mmol of iridium nitrate, 67mmol of glucose and 50mL of deionized water, mix and sonicate for 1h, then centrifuge (8000rpm) and dry at 80°C for 12h to obtain a solid product. Mix the solid product with melamine, control the mass ratio to 1:4, put it in an electric heating tube furnace and feed nitrogen gas, start the electric heating furnace and control the temperature rise rate to 10°C min -1 , heated to 700° C. and ...

Embodiment 2

[0048] Take 5g of sodium citrate and 5g of potassium citrate and mix them evenly, place them in an electric heating tube furnace and feed in argon gas, start the electric heating furnace and control the heating rate to 10°C min -1 , heated to 800°C and then pyrolyzed at constant temperature for 2h. The pyrolysis product was treated with 0.5M H 2 SO 4 The solution and deionized water were washed three times by centrifugation, and then dried in a vacuum oven at 60°C to obtain a porous carbon material. Take 0.8g of porous carbon material, 3mmol of nickel nitrate, 3mmol of iridium nitrate, 67mmol of glucose and 50mL of deionized water, mix and sonicate for 1h, then centrifuge (8000rpm) and dry at 80°C for 12h to obtain a solid product. Mix the solid product with melamine, control the mass ratio to 1:5, place it in an electric heating tube furnace and feed nitrogen gas, start the electric heating furnace and control the temperature rise rate to 10°C min -1 , heated to 800° C. an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com