Method for deeply removing phosphorus by mineral packed column

A technology of packed columns and minerals, used in chemical instruments and methods, water pollutants, multi-stage treatment of water/sewage, etc., can solve the problems of low electrodialysis and reverse osmosis efficiency, difficult to achieve stable total phosphorus standards, and high cost. , to achieve the effect of realizing solid waste recycling, convenient local material acquisition, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] Example 1Fe 2+ to PO 4 Enhancement by -P removal

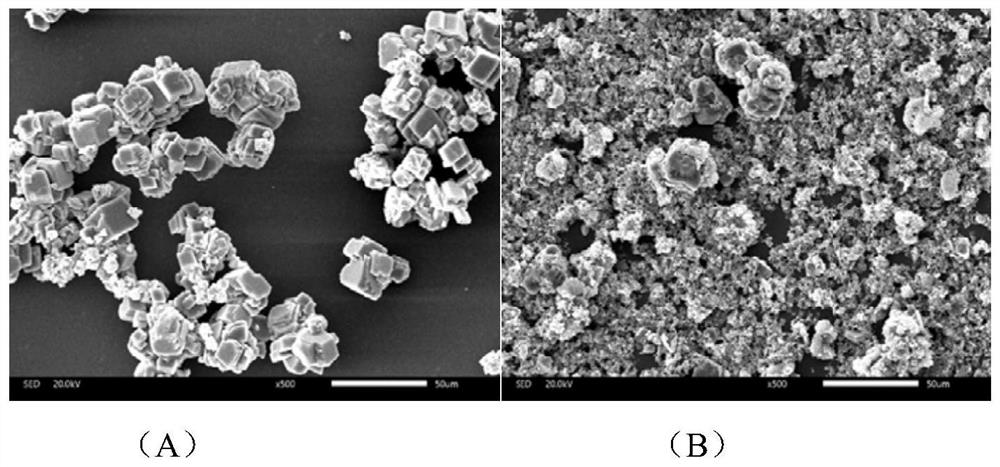

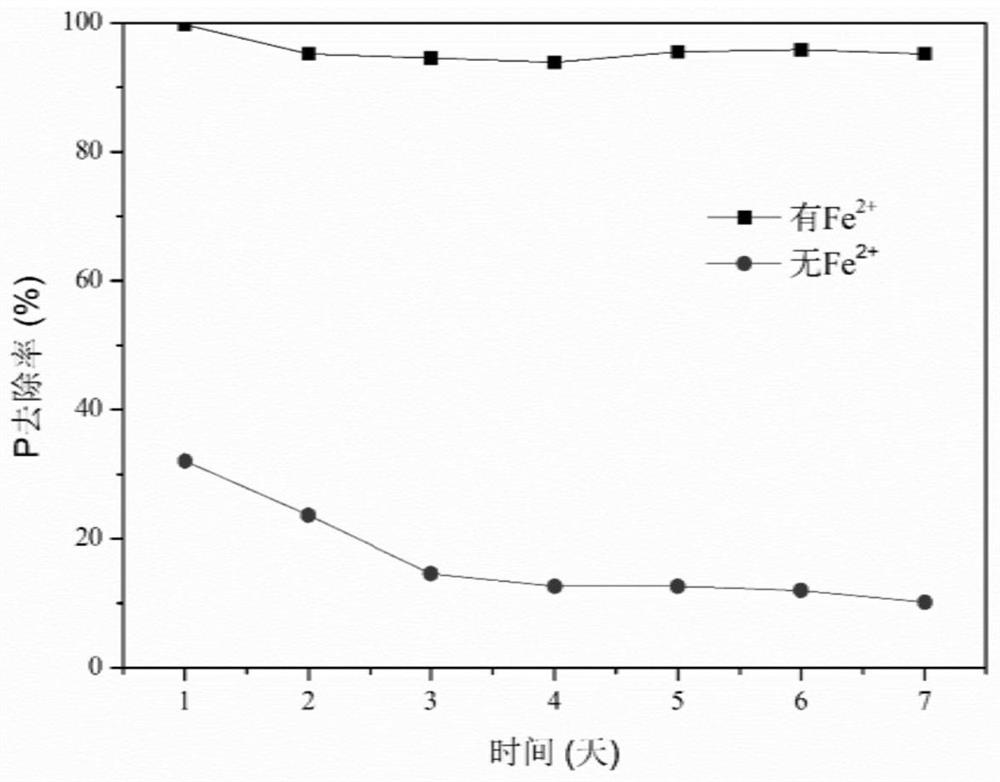

[0033] 1. Mix 100mg CaCO 3 Particles added to Fe 2+ 100mL FeSO with a concentration of 200mg / L 4 solution, and stirred with a magnetic stirrer at a speed of 500 rpm for 240 minutes. Using a scanning electron microscope to observe the characteristics of particle morphology changes before and after the action, the results are as follows figure 1 shown. figure 2 -A means CaCO 3 The original morphology of the particles is a typical hexagonal crystal structure with regular and complete morphology. After Fe 2+ After the action, its appearance is as figure 2 -B, most CaCO 3 The particles have been dissociated into irregular fine particles, which proves that Fe 2+ to CaCO 3 has obvious corrosive effect, therefore, it can be deduced that in solution, Fe 2+ Can significantly promote CaCO 3 Medium Ca 2+ dissolution.

[0034] 2. Using CaCO 3 Particle packed filter column to treat the same batch containing PO 4 -...

Embodiment 2

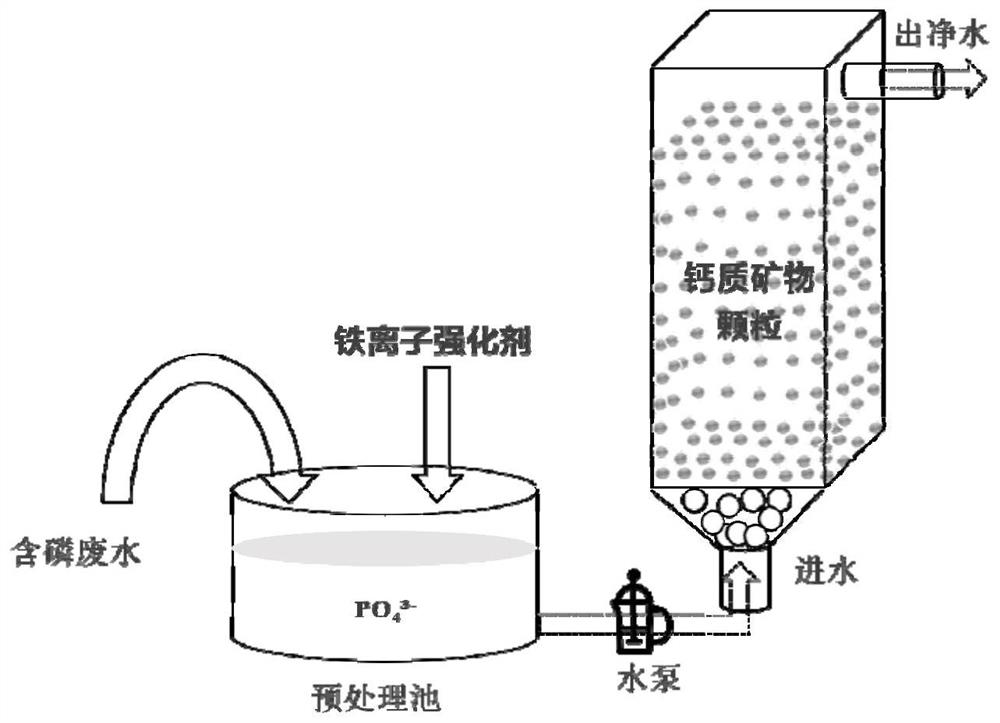

[0037] Embodiment 2 A kind of method for the deep phosphorus removal of mineral packed column

[0038] Fill the calcite particles into the cuboid column, the calcite filler particle size distribution (weight ratio): 3 PO 4 ) is configured to contain P concentration and be 0.5mg / L to be treated liquid 10L, and adjust pH to be 7.0. The 2L beaker is used as the pretreatment pond, controls Fe / P=1, adds 0.016mM ferrous sulfate in the phosphorus-containing sample of every liter (FeSO 4 ), the magnetic stirring speed is 100rpm, after stirring evenly, the solution in the beaker is transported into the column from the bottom of the filter column with a peristaltic pump, and the flow rate is controlled to keep the hydraulic retention time in the column to be 10min. Samples were taken every 12 hours at the discharge port on the upper part of the filter column, and the total Fe and total P content in the sample was detected. After continuous operation for 7 days, the results showed that ...

Embodiment 3

[0039] Embodiment 3 A kind of method for the deep phosphorus removal of mineral packed column

[0040] Fill the limestone particles into the cuboid column, the particle size distribution of limestone filler (weight ratio): 3 PO 4 ) is configured to contain P concentration and be 3mg / L to be treated liquid 10L, and adjusting pH is 7.0. The 2L beaker is used as pretreatment pool, controls Fe / P=1, adds 0.097mM iron nitrate (Fe nitrate) in the phosphorus-containing sample of every liter (NO 3 ) 3 ), the magnetic stirring speed is 100rpm, after stirring evenly, the solution in the beaker is transported into the column body from the bottom of the filter column with a peristaltic pump, and the flow rate is controlled to keep the hydraulic retention time in the column body at 30min. Samples are taken every 12 hours at the outlet of the upper part of the filter column, and the total Fe and total P content in the sample is detected. After 7 days of continuous operation, the results sh...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Removal rate | aaaaa | aaaaa |

| Removal rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com