1, 2-dichloroethane purification method in vinyl chloride production process

A production process, dichloroethane technology, applied in chemical instruments and methods, disproportionation separation/purification of halogenated hydrocarbons, organic chemistry, etc., can solve the problems of multi-tower refining and multiple condensers, so as to improve the separation effect and save Equipment investment and energy consumption, the effect of simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

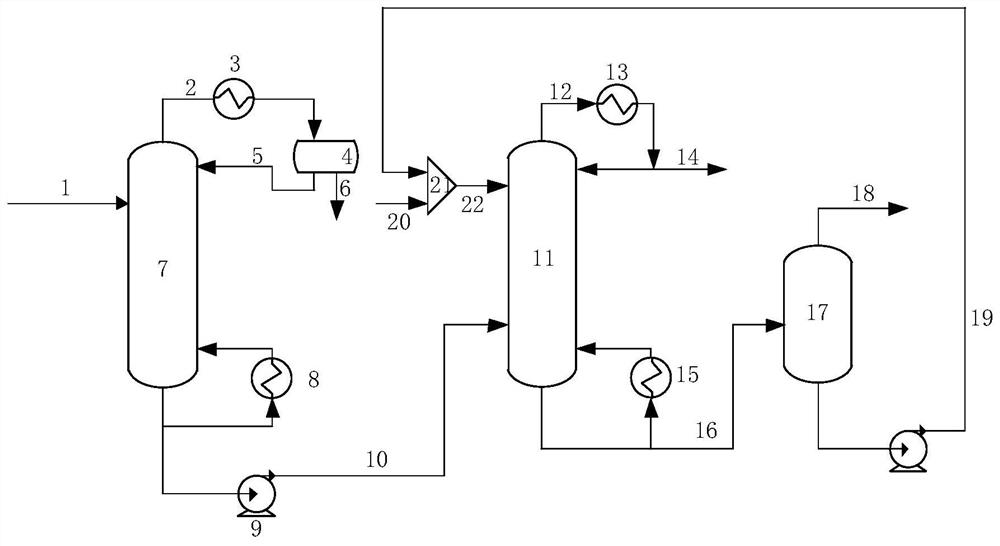

[0033] The crude EDC material enters the dehydration and lightening tower to remove the mixture of water and light components, and the mixture of EDC and heavy components at the bottom of the tower enters the extractive distillation tower, the extractant enters from the top of the extractive distillation tower, and the refined EDC comes from the extractive distillation tower Extraction from the top of the tower, the mixture of extractant and heavy components at the bottom of the tower enters the flash tank for separation, heavy components are extracted from the top of the flash tank, and the extractant is recovered from the bottom of the flash tank and recycled to the extractive distillation column for reuse.

[0034] In this example, the dehydration and lightening tower is a plate tower with 70 plates, and the feeding position of the crude EDC material is the 40th plate; the temperature at the top of the tower is 70°C, the temperature at the bottom of the tower is 110°C, and th...

Embodiment 2

[0042] The technical process in this embodiment is identical with embodiment 1, and difference is:

[0043] The dehydration and lightening tower is a packed tower with 75 trays, the feeding position of the crude EDC material is the 55th tray, the temperature at the top of the tower is 80°C, the temperature at the bottom of the tower is 120°C, and the operating pressure is 0.20MPag.

[0044] The extractive distillation column is a tray column with 30 trays, and the feeding position of the mixture of EDC and heavy components is the 25th tray. In the mixed extractant, choline chloride + oxalic acid (1:1.5) and choline chloride + The mass ratio of ethylene glycol (1:4) is 1:2.5, the mass ratio of extractant to mixture is 1:4, the temperature at the top of the tower is 90°C, and the temperature at the bottom of the tower is 150°C.

[0045] The pressure of the flash tank is 0.05kPa and the temperature is 170°C.

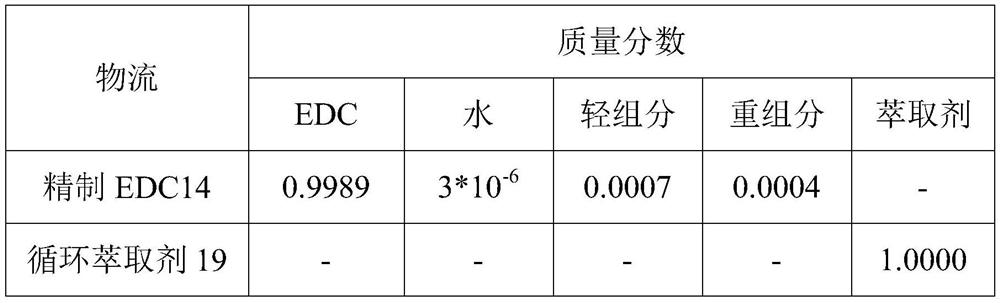

[0046] The composition of the target product refined EDC stream 14 an...

Embodiment 3

[0051] The technical process in this embodiment is identical with embodiment 1, and difference is:

[0052] The dehydration and lightening tower is a tray tower with 50 trays, the feeding position of the crude EDC material is the 30th tray, the temperature at the top of the tower is 55°C, the temperature at the bottom of the tower is 105°C, and the operating pressure is 0.14MPag.

[0053] The extractive distillation column is a plate column with 15 plates, and the feeding position of the mixture of EDC and heavy components is the 10th plate. In the mixed extractant, choline chloride + oxalic acid (1:1.5) and choline chloride + The mass ratio of ethylene glycol (1:4) is 1:3, the mass ratio of extractant to mixture is 1:1, the temperature at the top of the tower is 95°C, and the temperature at the bottom of the tower is 170°C.

[0054] The pressure of the flash tank is 0.06kPa and the temperature is 180°C.

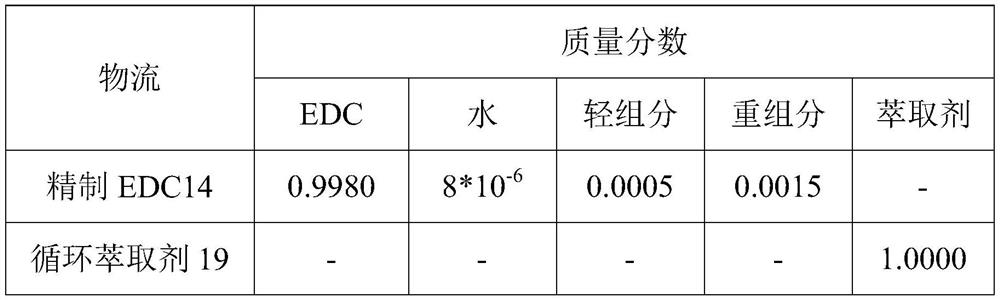

[0055] The composition of the target product refined EDC stream 14 and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com