Preparation method of corrosion-resistant structural adhesive for wind turbine blade

A wind power blade and corrosion-resistant technology, which is applied in the field of preparation of corrosion-resistant structural adhesives for wind power blades, can solve the problems of structural adhesive layer thickness changes, bonding performance effects, and affecting the gap between the skin and the web

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Furfuryl alcohol resin was purchased from Zhengzhou Hengtong Chemical Co., Ltd., chlorinated polyethylene was purchased from Linyi Anfeng Chemical Co., Ltd. CPE-135A, Qinghe County Chuangying Metal Material Co., Ltd. flake graphite DK202, Haicheng Ruitong Mining Co., Ltd. chlorite powder , nepheline powder Unimin minex10, and barite powder were purchased from Qingdao Kailisen.

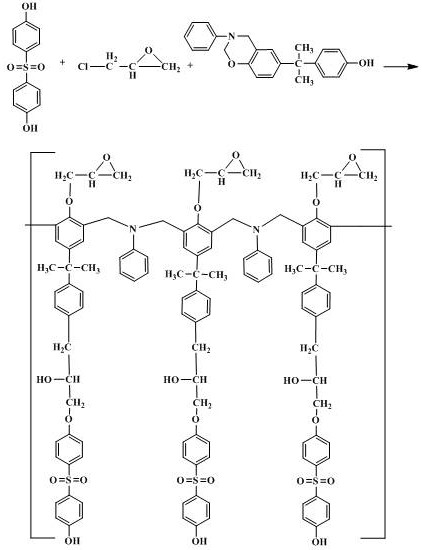

[0028] The first step, the preparation of bisphenol A benzoxazine resin: in parts by weight, add 119 parts of paraformaldehyde, 96 parts of aniline and 231 parts of bis For phenol A, add 232 parts of absolute ethanol as a solvent, continue the reaction at 80°C for 24h to end the reaction, remove the solvent in the reaction product by rotary evaporation to remove absolute ethanol, dry the product after rotary evaporation at 60°C for 4h in vacuum, and then use methanol The product after vacuum drying is washed 3 times, and then vacuum-dried at 75°C for 2 hours to obtain bisphenol A benzoxazine res...

Embodiment 2

[0031] Furfuryl alcohol resin was purchased from YJ-2 furfuryl alcohol resin of Shandong Mobei Chemical Co., Ltd., chlorinated polyethylene was purchased from CPE-135A of Linyi Aoxing Chemical Co., Ltd., flake graphite DK202 of Qinghe County Chuangying Metal Material Co., Ltd., Haicheng Ruitong Mining Co., Ltd. purchased chlorite powder, nepheline powder Unimin minex10, and barite powder from Qingdao Kailisen.

[0032] The first step, the preparation of bisphenol A benzoxazine resin: in parts by weight, add 113 parts of paraformaldehyde, 89 parts of aniline and 215 parts of bis For phenol A, add 215 parts of absolute ethanol as a solvent, continue the reaction at 75°C for 22h to end the reaction, remove the absolute ethanol by rotary evaporation of the solvent in the reaction product, dry the product after rotary evaporation at 50°C for 2h in vacuum, then wash with methanol The product after vacuum drying is washed 3 times, and then vacuum-dried at 70°C for 1 hour to obtain bi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com