Manufacturing method of lithium ion battery capable of resisting storage discharge to zero volt

A technology of lithium-ion battery and manufacturing method, which is applied to secondary batteries, battery electrodes, electrode carriers/collectors, etc., and can solve problems such as consumption, low battery voltage, and short circuit between positive and negative electrodes of the battery

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

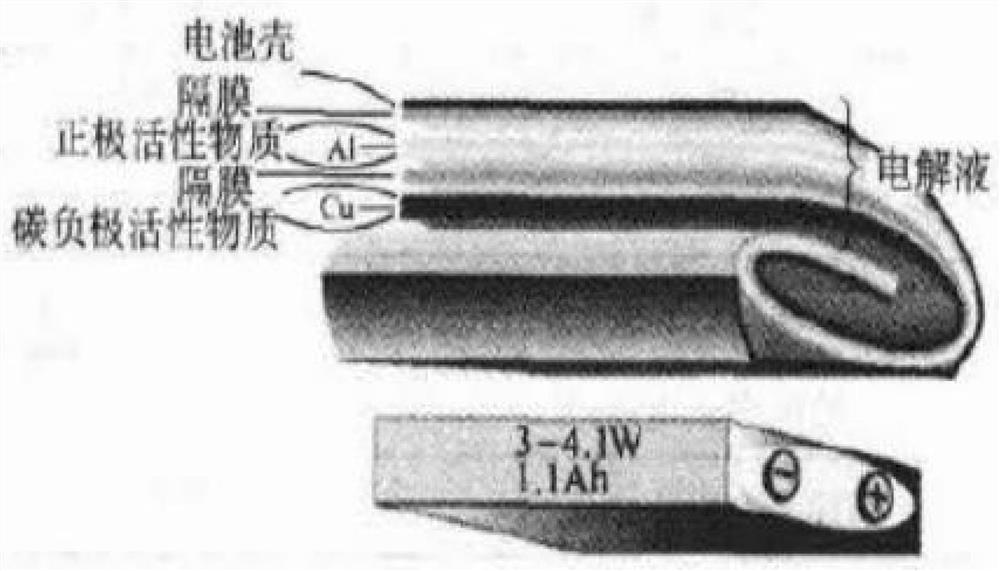

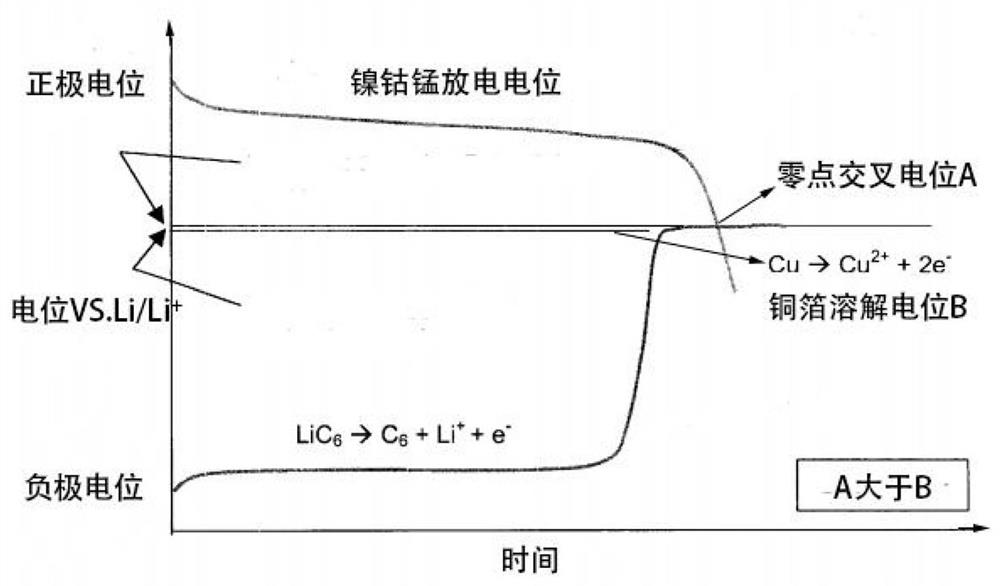

[0033] In this embodiment, a manufacturing method of a lithium-ion battery resistant to storage and discharge to zero volts:

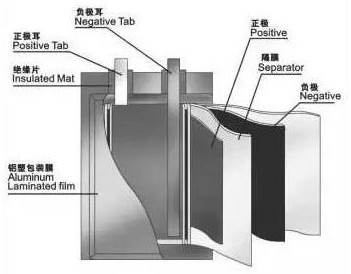

[0034] (1). Aluminum foil is used as the current collector for the positive electrode, and aluminum tabs are welded on the aluminum foil with an ultrasonic spot welder, and high-temperature insulating tape is pasted on both sides of the tabs; copper foil current collectors are used for the negative electrode, and copper foil current collectors are used as a control Group;

[0035] (2). On the negative current collector, also use an ultrasonic spot welding machine to weld nickel tabs, and paste high-temperature insulating tape on both sides of the tabs to avoid battery short circuit;

[0036] (3) According to the battery capacity and the balance value of the positive and negative electrode capacity, design the battery size, the thickness of the positive and negative electrodes, the amount of electrolytic addition and many other parameters;

[0037] (4)...

Embodiment 2

[0045] In this embodiment, a manufacturing method of a lithium-ion battery resistant to storage and discharge to zero volts:

[0046] (1). The positive electrode uses aluminum foil as the current collector, and the aluminum tab is welded on the aluminum foil with an ultrasonic spot welder, and the two sides of the tab are glued with high-temperature insulating tape; the negative electrode uses a titanium foil current collector, and at the same time, uses a copper foil current collector as a control Group;

[0047] (2). On the negative current collector, also use an ultrasonic spot welding machine to weld nickel tabs, and paste high-temperature insulating tape on both sides of the tabs to avoid battery short circuit;

[0048] (3) According to the battery capacity and the balance value of the positive and negative electrode capacity, design the battery size, the thickness of the positive and negative electrodes, the amount of electrolytic addition and many other parameters;

[00...

Embodiment 3

[0057] In this embodiment, a manufacturing method of a lithium-ion battery resistant to storage and discharge to zero volts:

[0058] (1). The positive electrode uses aluminum foil as the current collector, and the aluminum tab is welded on the aluminum foil with an ultrasonic spot welder, and the two sides of the tab are glued with high-temperature insulating tape; the negative electrode uses a titanium foil current collector, and at the same time, uses a copper foil current collector as a control Group;

[0059] (2). On the negative current collector, also use an ultrasonic spot welding machine to weld nickel tabs, and paste high-temperature insulating tape on both sides of the tabs to avoid battery short circuit;

[0060] (3) According to the battery capacity and the balance value of the positive and negative electrode capacity, design the battery size, the thickness of the positive and negative electrodes, the amount of electrolytic addition and many other parameters;

[...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com