Method for preparing nonivamide

A technology for vanillamide and n-nonanoic acid, applied in the field of preparing vanillamide n-nonanoic acid, can solve the problems of low yield, unenvironmental protection, complicated post-processing and the like, achieve simple post-processing, avoid the use of organic solvents, and avoid sodium salts The effect of pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] The preparation of embodiment 1 aryl boronic acid

[0031] The aryl boronic acid of the present invention is prepared by a prior art method: Synthesis, evaluation and application of novel bifunctional N, N-diisopropylbenzylamine boronic acid catalysts for direct amide formation between carboxylic acids and amines, Green Chemistry, 2008.

Embodiment 2

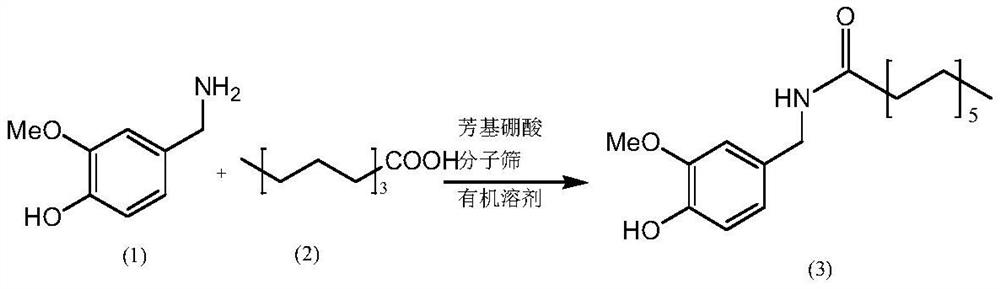

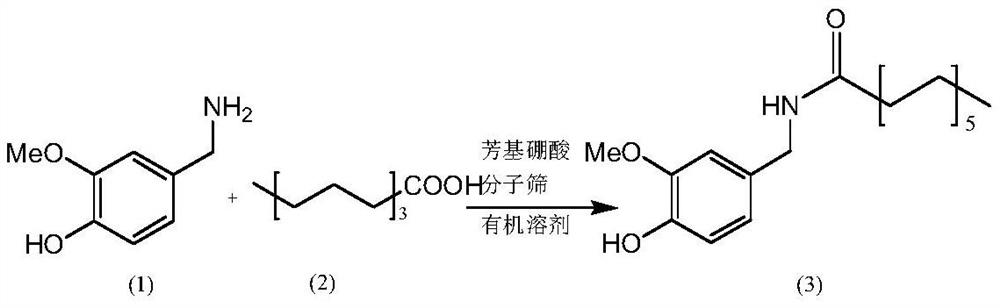

[0033] Add 2-((N,N-diisopropyl)methyl)phenylboronic acid (0.0327mol, 10mol%) to 200ml methylene chloride in a 500ml three-necked flask, add active Stir with molecular sieves, add 50g (0.327mol) of 3-methoxy-4-hydroxybenzylamine at room temperature, stir and heat to reflux at 40°C, add 43g (0.272mol) of n-nonanoic acid dropwise through the dropping funnel, and keep stirring at reflux for 0.5h After the reaction, cool down to room temperature, add 100ml of water and stir for 5 minutes, then let stand to separate layers, take the oily layer, and distill under reduced pressure at 30°C to recover dichloromethane, stop the reduced-pressure distillation after obtaining a light yellow transparent liquid, cool the remaining liquid to room temperature, and forcefully After stirring for 30 min, 79.6 g of white solid powder was precipitated, with a yield of 95.8% and a purity of 99.3% by HPLC.

[0034] White powder solid analysis

[0035] NMR spectrum characterization: 1H NMR (CDCl3, TM...

Embodiment 3

[0039] Add 2-((N,N-dimethyl)methyl)phenylboronic acid (0.0327mol, 10mol%) to 200ml toluene in a 500ml three-necked flask, add active Stir with molecular sieves, add 50g (0.327mol) of 3-methoxy-4-hydroxybenzylamine at room temperature, stir and heat to reflux at 110°C, add 43g (0.272mol) of n-nonanoic acid dropwise through the dropping funnel, and keep stirring at reflux for 2.5h After the reaction, cool down to room temperature, add 100ml of water and stir for 5 minutes, then let stand to separate layers, take the oily layer, and recover toluene by vacuum distillation at 60°C, stop the vacuum distillation after obtaining a light yellow transparent liquid, cool the remaining liquid to room temperature, and stir vigorously for 30 minutes , 78.9 g of white solid powder was precipitated, the yield was 95.0%, and the HPLC purity was 99.1%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com