Ethyl propionate grafted polysiloxane, preparation method and application thereof

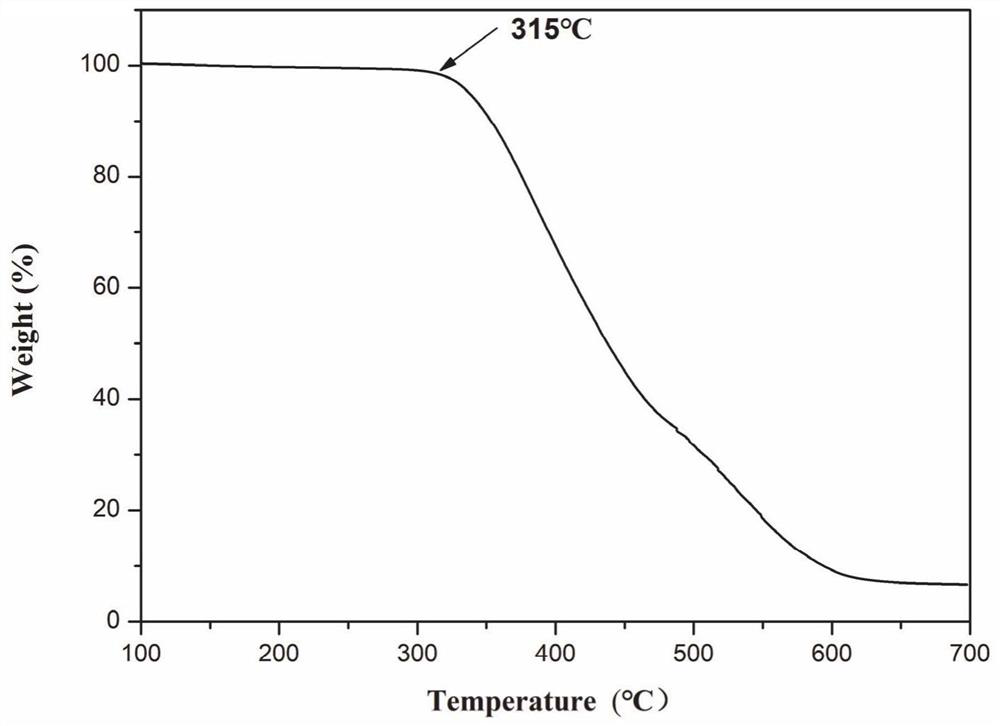

A technology of polysiloxane and ethyl propionate, applied in chemical instruments and methods, other chemical processes, ion exchange, etc., can solve problems such as temperature range limitation, chromatographic peak tailing, etc., to achieve enhanced separation selectivity, Increased grafting rate and excellent temperature resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

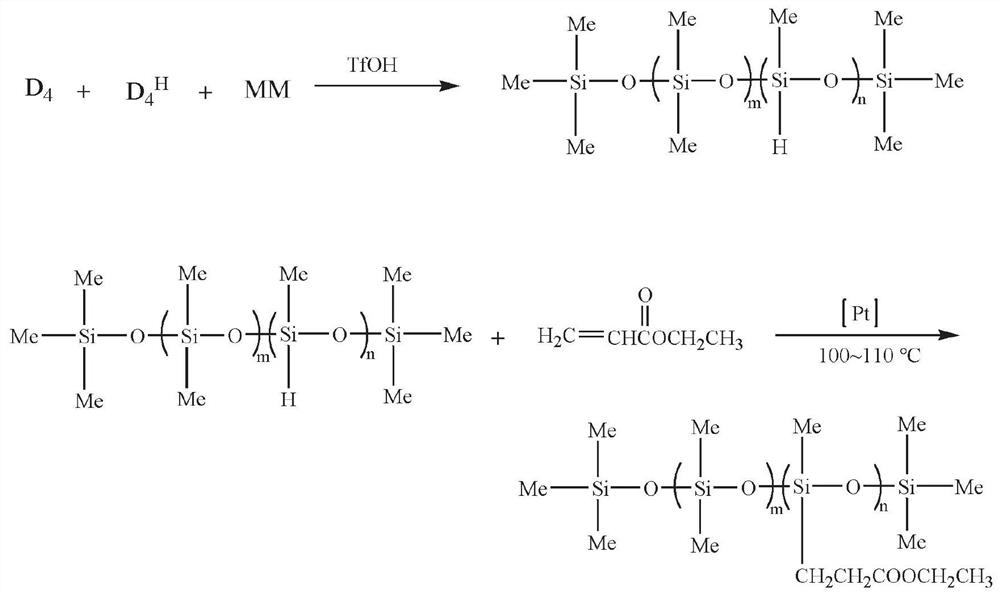

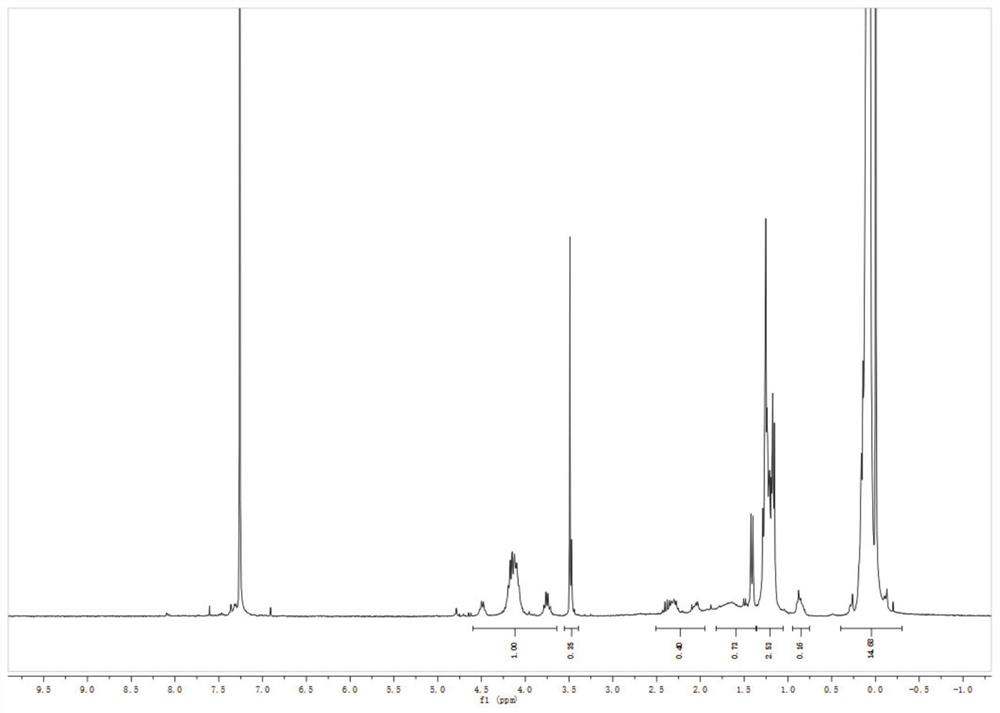

[0049] Ethyl propionate graft polysiloxane, the preparation method is as follows:

[0050] (1) Preparation of methyl hydrogen-containing silicone oil with a Si-H chain link content of 25%: according to m:n=3:1 feeding, 26.57g D 4 (0.09mol), 7.2g D 4 H (0.03mol) was added into a 250mL four-neck flask, 0.02mL trifluoromethanesulfonic acid was added, and the reaction was stirred at room temperature for 24h. When the molecular weight of the reactant gradually increased and became viscous, 0.025 g of hexamethyldisiloxane was added as an end-capping agent. After 4 hours of reaction, a slight excess of ammonia water was added to remove trifluoromethanesulfonic acid, and the reaction was stopped after 1 hour. During the reaction, it can be seen that the substance in the reaction bottle gradually changes from a colorless and transparent liquid to a viscous polymer. Dissolve the product with 30mL of n-hexane, filter out the insoluble matter, then wash with distilled water until neutr...

Embodiment 2

[0057] Ethyl propionate graft polysiloxane, the preparation method is as follows:

[0058] (1) Preparation of methyl hydrogen-containing silicone oil with a Si-H chain link content of 25%: according to m:n=3:1 feeding, 26.57g D 4 (0.09mol), 7.2g D 4 H (0.03mol) was added into a 250mL four-neck flask, 0.02mL trifluoromethanesulfonic acid was added, and the reaction was stirred at room temperature for 24h. When the molecular weight of the reactant gradually increased and became viscous, 0.025 g of hexamethyldisiloxane was added as an end-capping agent. After 4 hours of reaction, a slight excess of ammonia water was added to remove trifluoromethanesulfonic acid, and the reaction was stopped after 1 hour. During the reaction, it can be seen that the substance in the reaction bottle gradually changes from a colorless and transparent liquid to a viscous polymer. Dissolve the product with 30mL of n-hexane, filter out the insoluble matter, then wash with distilled water until neutr...

Embodiment 3

[0063] Ethyl propionate graft polysiloxane, the preparation method is as follows:

[0064] (1) Preparation of methyl hydrogen-containing silicone oil with a Si-H chain link content of 25%: according to m:n=3:1 feeding, 26.57g D 4 (0.09mol), 7.2g D 4 H (0.03mol) was added into a 250mL four-neck flask, 0.02mL trifluoromethanesulfonic acid was added, and the reaction was stirred at room temperature for 24h. When the molecular weight of the reactant gradually increased and became viscous, 0.025 g of hexamethyldisiloxane was added as an end-capping agent. After 4 hours of reaction, a slight excess of ammonia water was added to remove trifluoromethanesulfonic acid, and the reaction was stopped after 1 hour. During the reaction, it can be seen that the substance in the reaction bottle gradually changes from a colorless and transparent liquid to a viscous polymer. Dissolve the product with 30mL of n-hexane, filter out the insoluble matter, then wash with distilled water until neutr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Column length | aaaaa | aaaaa |

| The inside diameter of | aaaaa | aaaaa |

| Column length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com