A kind of preparation method of lithium metal battery negative electrode side interlayer material that prevents lithium dendrite

A lithium metal battery, lithium dendrite technology, applied in battery electrodes, negative electrodes, secondary batteries, etc., can solve the problems of difficult to enlarge preparation, unreasonable structural design, etc., to reduce polarization phenomenon, stabilize peeling capacity, process Simple and effective process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

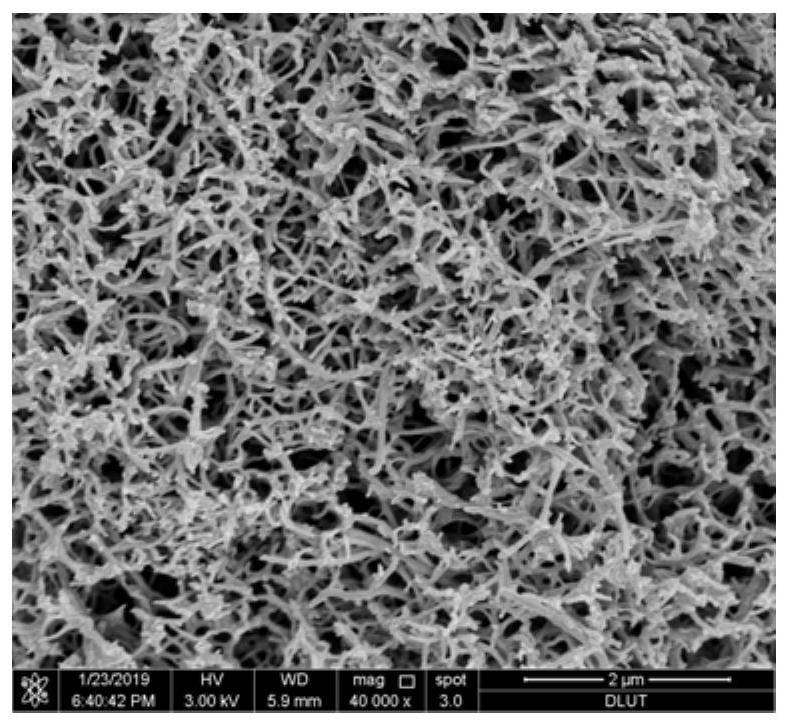

[0029] 1) Preparation of CNT@PAN composite membrane material

[0030] Weigh 1g of polyacrylonitrile (PAN), put it in a silk bottle, add 12g of N,N-dimethylformamide (DMF), stir for 30min, add 1g of carbon nanotubes (CNT), N,N-dimethylformamide The mass ratio of base formamide, carbon nanotubes and polyacrylonitrile is 12:1:1. Put the silk bottle in an oil bath, stir at 60-80°C for 8-12h, and form a uniform and viscous black casting solution. After the casting solution was cooled to room temperature, an automatic coating machine was used to coat the casting solution on a dry and clean glass plate to form a liquid film with a thickness of 200 μm. The glass plate was quickly transferred to n-pentanol, and the CNT@PAN composite film was formed based on the principle of phase inversion. After soaking for 24 hours, it was taken out to dry, and then transferred to a vacuum drying oven, and vacuum-dried at 90°C for 4 hours to remove the CNT@PAN composite film. remaining n-pentanol. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com