Integrated production process for ternary material

A ternary material and production process technology, applied in the direction of electrical components, electrochemical generators, structural parts, etc., can solve the problems of time-consuming and labor-intensive safety, high power consumption of a single machine, and a large amount of washing liquid, etc., to achieve convenient use, Guarantee the effect of high production capacity, production efficiency and high purity requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

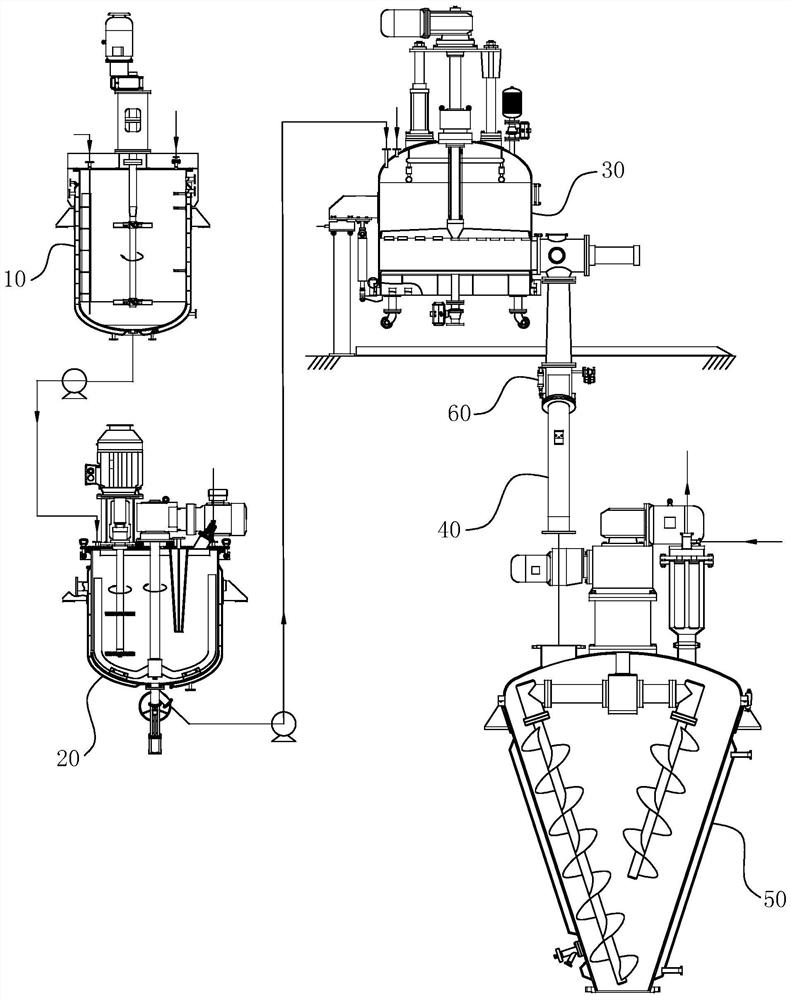

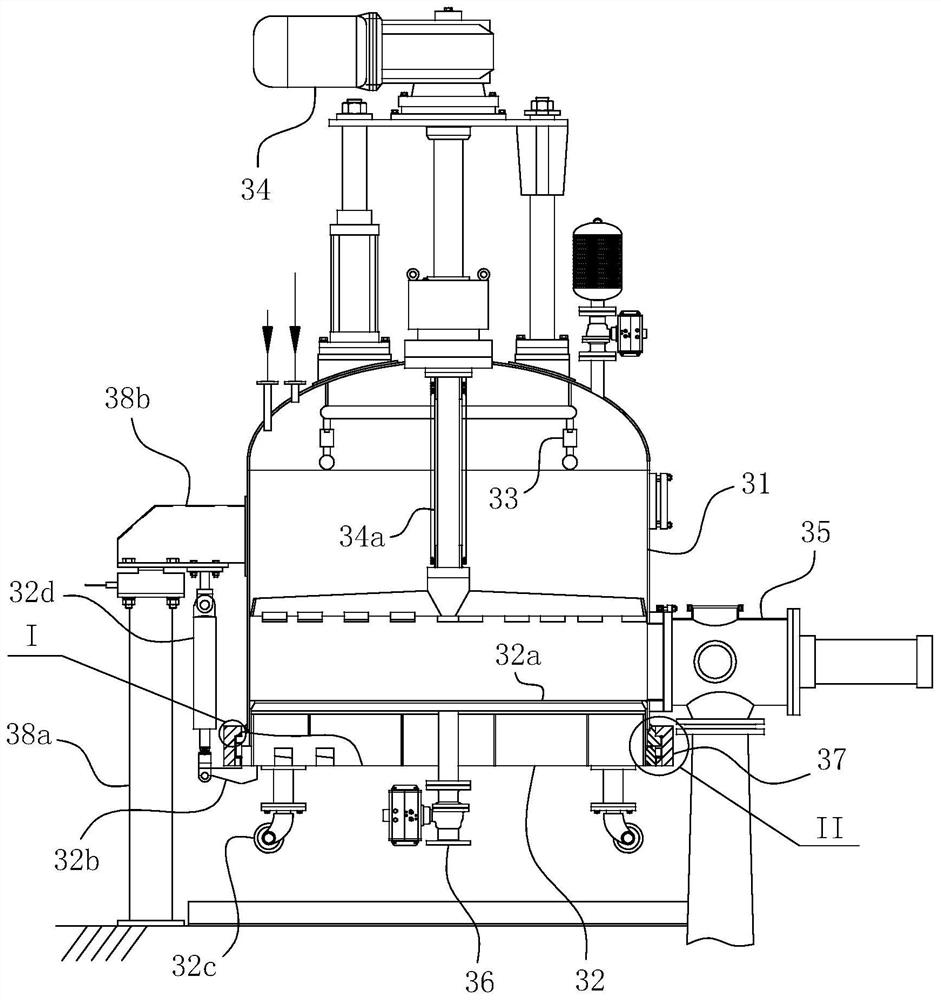

[0054] For ease of understanding, the specific structure and working method of the present invention are further described as follows in combination with the overall ternary material production system and process:

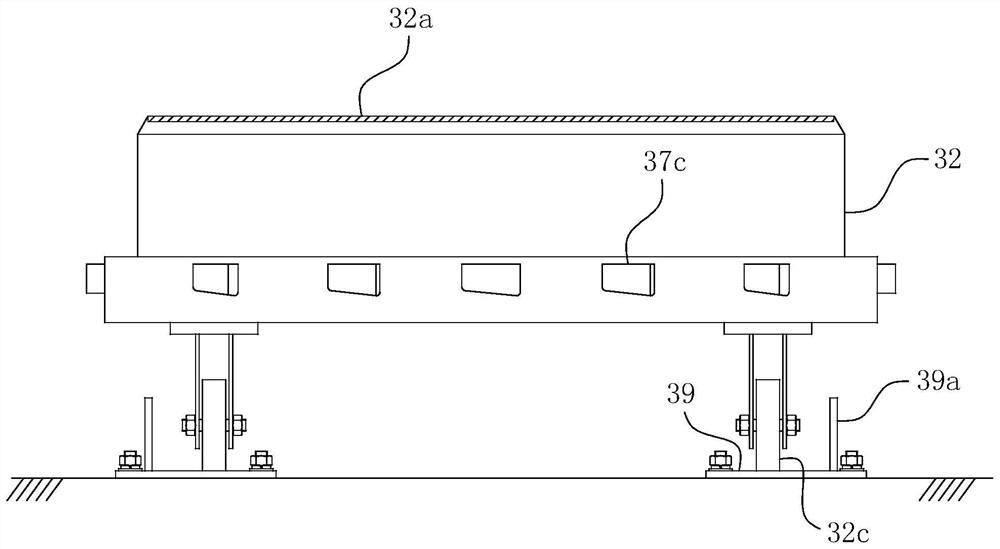

[0055] The production system based on ternary materials provided by the present invention is based on the stirred tank filter 30, and organically integrates functions such as airtight pressure filtration, stirring slurry washing, automatic rotating unloading, and self-heating into the stirring tank Type filter 30, so that the overall structure is compact and optimized, thereby effectively shortening the process flow. Based on the structure of the stirred tank filter 30, the materials can be fully dispersed and reacted by equipping the high-efficiency water washing kettle 20 in the front-end process; the twin-screw dryer 50 is equipped in the rear end so that the materials can be fully mixed, Efficient drying without damage to the crystal form of the material, and f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com