High-strength thermal insulation concrete and preparation method thereof

A heat-preserving concrete and high-strength technology, applied in the field of building materials, can solve problems affecting performance, low foam concrete strength, high water absorption, etc., and achieve the effects of prolonging service life, improving weather resistance, and improving waterproof performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

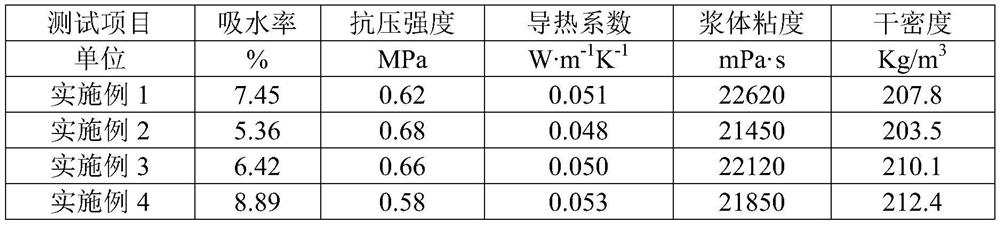

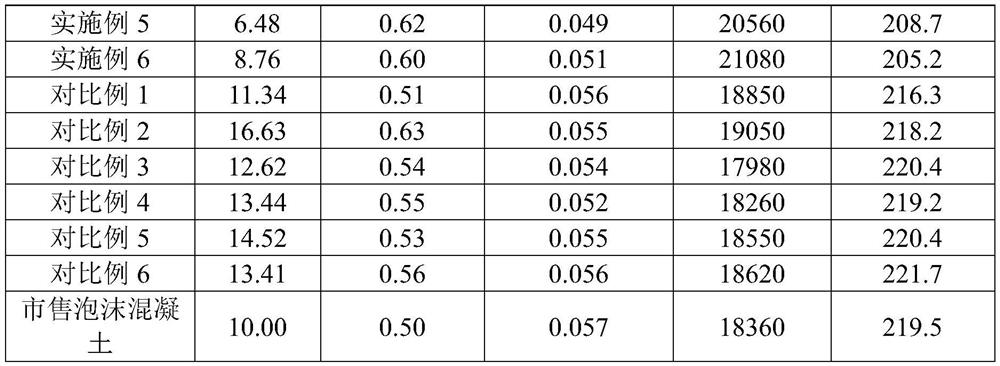

Examples

Embodiment 1

[0032] A high-strength thermal insulation concrete, characterized in that, in terms of mass percentage, its formulation raw materials are as follows: 30% of ordinary portland cement, 20% of titanium waste residue, 10% of red gypsum, 3% of polymer emulsion, foaming agent 1.5%, calcium stearate 1%, lithium chloride 2%, superplasticizer 0.6%, polypropylene fiber 0.1%, and the balance is water.

[0033] The polymer emulsion is formed by polymerizing methacrylic acid sulfobetaine monomer, vinylidene fluoride, deionized water and co-solvent under the action of an initiator.

[0034] The preparation method of the polymer emulsion comprises the following steps: stirring the sulfobetaine monomer of methacrylic acid, vinylidene fluoride, deionized water and a cosolvent, and then raising the temperature to 70° C. to form a mixed solution, and then adding an initiator to the mixed solution. agent, reacted at 70°C under nitrogen for 12 hours, and stopped the reaction by blowing in air, and...

Embodiment 2

[0043]A high-strength thermal insulation concrete, characterized in that, in terms of mass percentage, its formulation raw materials are as follows: 35% of ordinary Portland cement, 23% of titanium waste residue, 13% of red gypsum, 6% of polymer emulsion, foaming agent 3%, calcium stearate 1.5%, lithium chloride 2.5%, superplasticizer 0.7%, polypropylene fiber 0.2%, and the balance is water.

[0044] The polymer emulsion is formed by polymerizing methacrylic acid sulfobetaine monomer, vinylidene fluoride, deionized water and co-solvent under the action of an initiator.

[0045] The preparation method of the polymer emulsion comprises the following steps: Stirring methacrylic acid sulfobetaine monomer, vinylidene fluoride, deionized water and co-solvent, then raising the temperature to 75°C to form a mixed solution, and then adding initiator agent, reacted in helium at 75°C for 10 hours, passed air to stop the reaction, and cooled to room temperature to obtain a polymer emulsio...

Embodiment 3

[0054] A high-strength thermal insulation concrete, characterized in that, in terms of mass percentage, the composition of its formula raw materials is as follows: 40% of ordinary portland cement, 25% of titanium waste residue, 15% of red gypsum, 8% of polymer emulsion, foaming agent 5%, calcium stearate 2%, lithium chloride 3%, superplasticizer 0.8%, polypropylene fiber 0.3%, and the balance is water.

[0055] The polymer emulsion is formed by polymerizing methacrylic acid sulfobetaine monomer, vinylidene fluoride, deionized water and co-solvent under the action of an initiator.

[0056] The preparation method of the polymer emulsion comprises the following steps: stirring the sulfobetaine monomer of methacrylic acid, vinylidene fluoride, deionized water and a cosolvent, and then raising the temperature to 80° C. to form a mixed solution, and then adding an initiator to the mixed solution. agent, reacted in neon gas at 80°C for 8 hours, passed air to stop the reaction, and co...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com