Nitrogen-containing compound, organic electroluminescent device using same, and electronic device

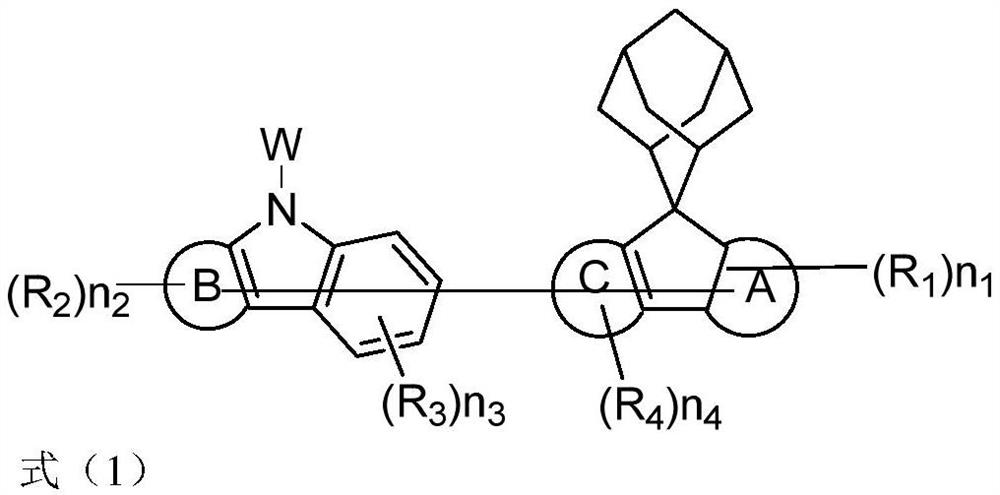

A nitrogen compound and chemical formula technology, applied in the field of organic electroluminescent materials, can solve the problems of short luminous life and low luminous efficiency, and achieve the effects of improving recombination rate, adjusting stacking degree, and enhancing hole mobility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Synthetic example

[0204] In the synthesis examples described below, all temperatures are in degrees Celsius unless otherwise stated. Some reagents were purchased from commercial suppliers such as Aldrich Chemical Company, Arco Chemical Company and Alfa Chemical Company, and were used without further purification unless otherwise stated. The rest of the conventional reagents are from Shantou Xilong Chemical Factory, Guangdong Guanghua Chemical Reagent Factory, Guangzhou Chemical Reagent Factory, Tianjin Haoyuyu Chemical Co., Ltd., Tianjin Fuchen Chemical Reagent Factory, Wuhan Xinhuayuan Technology Development Co., Ltd., Qingdao Tenglong It can be purchased from Chemical Reagent Co., Ltd. and Qingdao Ocean Chemical Factory. Anhydrous tetrahydrofuran, dioxane, toluene, ether and other anhydrous solvents are obtained by reflux drying of metal sodium. Anhydrous dichloromethane and chloroform were obtained by refluxing and drying over calcium hydride. Ethyl acetate, petroleum ether, n-hexane, N,N-...

Embodiment 1

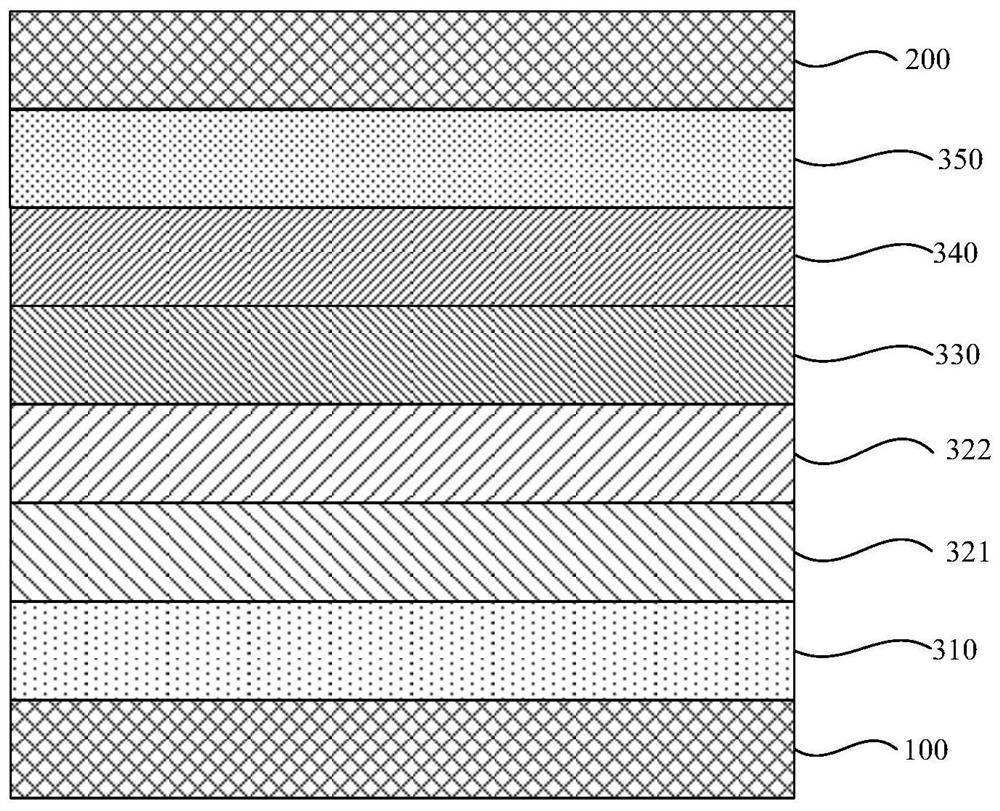

[0277] Embodiment 1: green organic electroluminescent device

[0278] Use the following methods to fabricate green organic electroluminescent devices:

[0279] The anode was prepared by the following process: the thickness of ITO was The ITO substrate was cut into a size of 40mm (length) × 40mm (width) × 0.7mm (thickness), and it was prepared into an experimental substrate with cathode, anode and insulating layer patterns by photolithography process, and ultraviolet ozone and o 2 :N 2 Plasma is used for surface treatment to increase the work function of the anode, and organic solvents can be used to clean the surface of the ITO substrate to remove impurities and oil on the surface of the ITO substrate. It should be noted that the ITO substrate can also be cut into other sizes according to actual needs, and there is no special limitation on the size of the ITO substrate in this application.

[0280] F4-TCNQ was vacuum evaporated on the experimental substrate (anode) to for...

Embodiment 17

[0297] Example 17: Red organic electroluminescence device

[0298] The anode was prepared by the following process: the thickness of ITO was The ITO substrate was cut into a size of 40mm (length) × 40mm (width) × 0.7mm (thickness), and it was prepared into an experimental substrate with cathode, anode and insulating layer patterns by photolithography process, and ultraviolet ozone and o 2 :N 2 Plasma is used for surface treatment to increase the work function of the anode, and organic solvents can be used to clean the surface of the ITO substrate to remove impurities and oil on the surface of the ITO substrate. It should be noted that the ITO substrate can also be cut into other sizes according to actual needs, and there is no special limitation on the size of the ITO substrate in this application.

[0299] F4-TCNQ was vacuum evaporated on the experimental substrate (anode) to form a thickness of The hole injection layer (HIL), and HT-01 is evaporated on the hole injecti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com