Method for preparing FeAl intermetallic compound flexible film through activated sintering of pre-alloyed powder

A technology of intermetallic compounds and pre-alloyed powders, which is applied in the field of FeAl intermetallic compound flexible membranes prepared by activation and sintering of pre-alloyed powders, which can solve the problems of insufficient toughness and thermal shock resistance, high temperature resistance, and corrosion resistance of ceramic filter materials. Common tubular filter materials have problems such as large thickness, and achieve the effects of good high temperature oxidation resistance and corrosion resistance, good mechanical properties and fatigue resistance, and good powder composition uniformity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

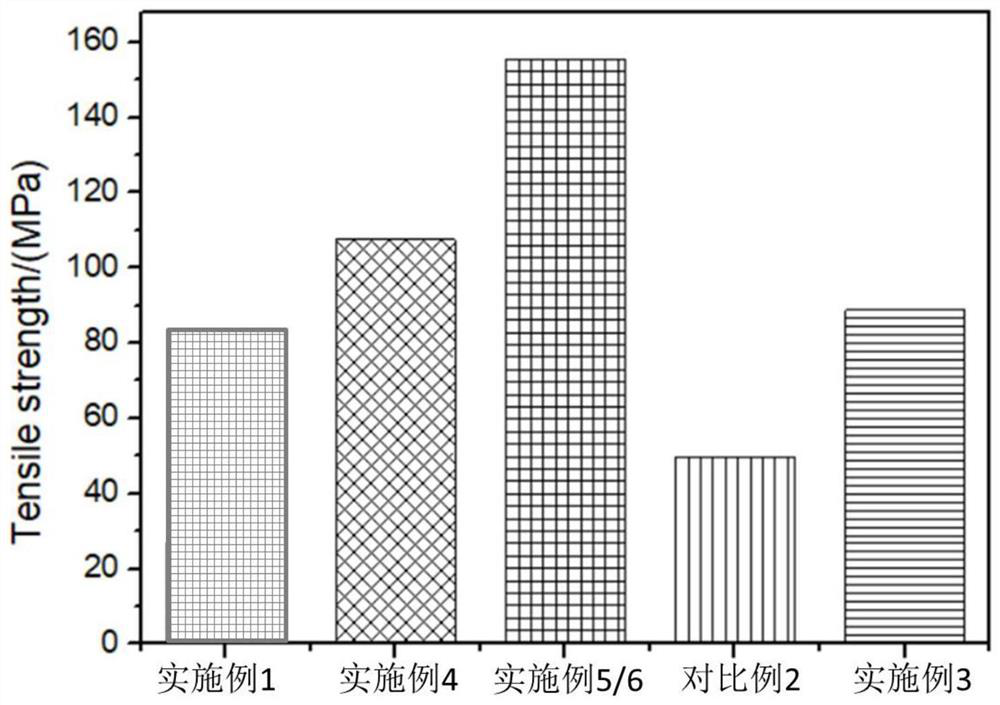

Examples

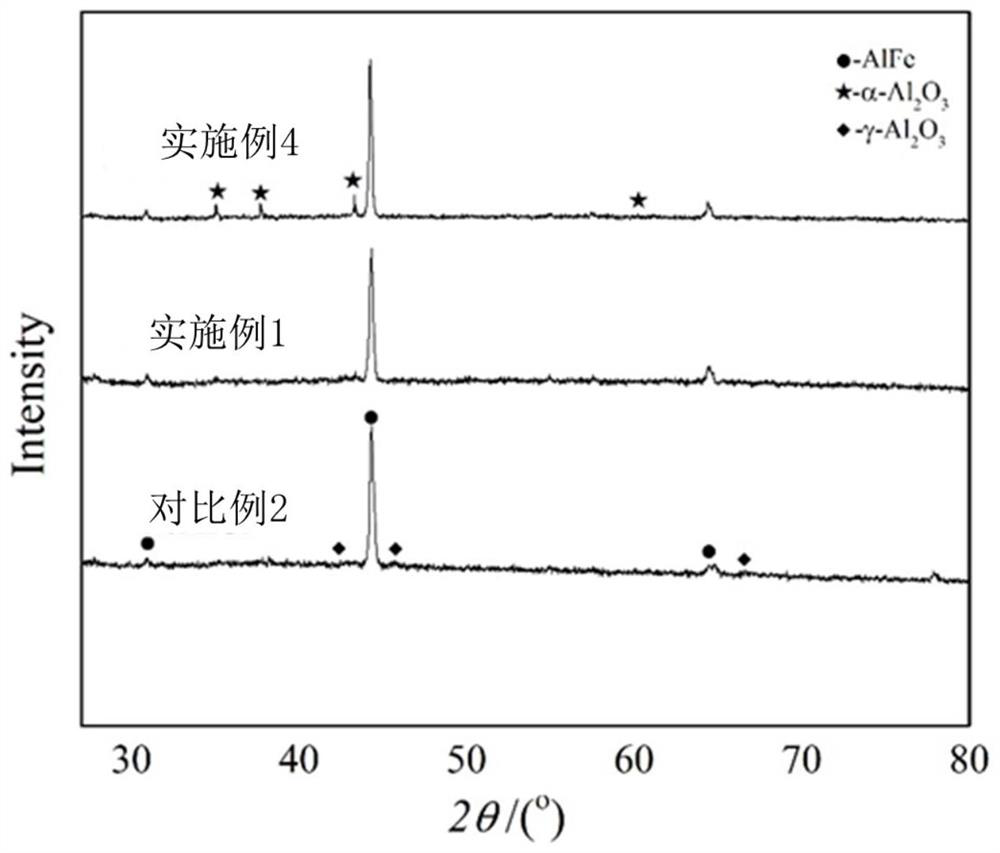

Embodiment 1

[0043] A method for preparing FeAl intermetallic compound flexible film by pre-alloy powder sintering method:

[0044] 1. Powder blending: add 5g of thermoplastic phenolic resin to 30mL of ethanol, then add 100g of FeAl aerosolized spherical alloy powder (in which the aluminum content is 10wt.%, and the balance is Fe), then add a sintering activator (calculated by element, Contains 0.5g of boron, added in the form of elemental boron and ferroboron powder); it is prepared into a uniform slurry of suspended particles by mechanical stirring.

[0045] 2. Ball milling: place the suspended particle slurry prepared in step 1 in a planetary ball mill for mechanical ball milling, the ball-to-material ratio is 3:1, and the ball milling time is 24 hours to obtain a uniform composite of activator and FeAl-based alloy powder. Irregular energy storage powder.

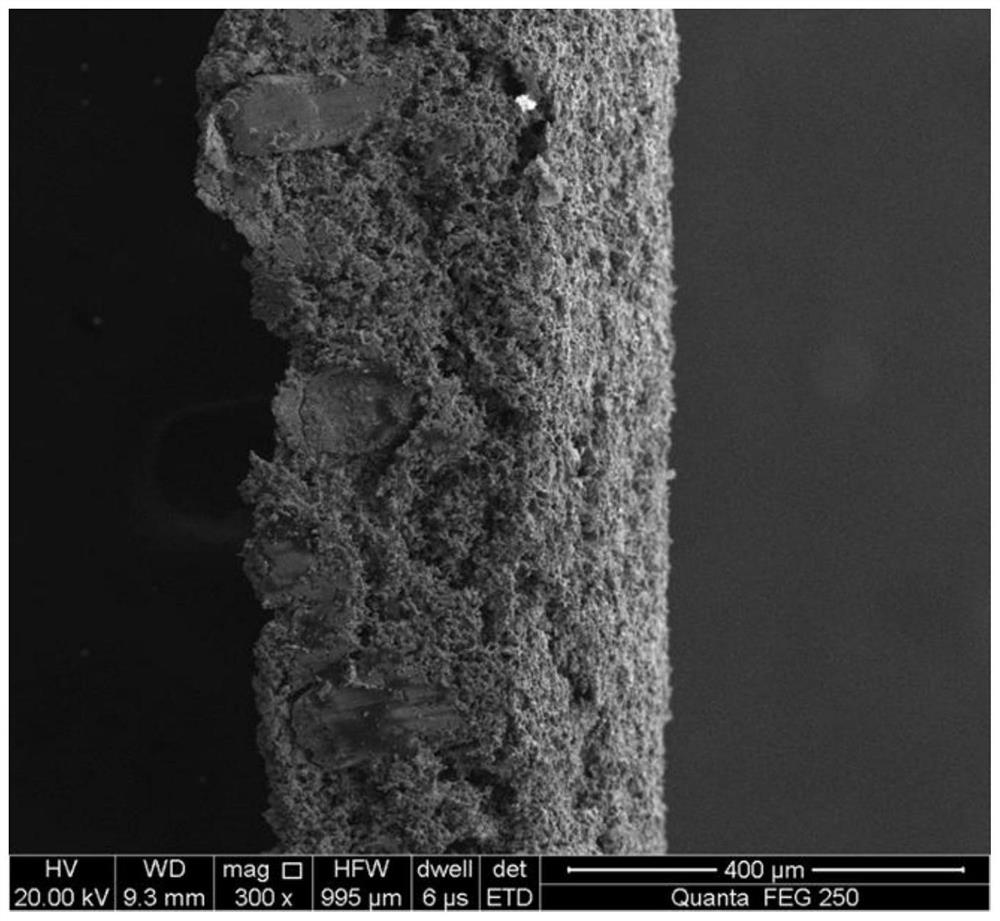

[0046] 3. Sizing: Spray a layer of uniform FeAl pre-alloyed powder composite slurry on the 310S stainless steel mesh (the mesh dia...

Embodiment 2

[0050] A method for preparing FeAl intermetallic compound flexible film by pre-alloy powder sintering method:

[0051] 1. Powder blending: add 8g of thermoplastic phenolic resin to 35mL of ethanol, then add 100g of FeAl aerosolized spherical alloy powder (wherein the aluminum content is 20wt.%, the balance is Fe), and then add a sintering activator (calculated by element, It contains 0.2g of boron, 0.3g of yttrium, and is added in the form of metal yttrium and yttrium boride); it is prepared into a uniform suspended particle slurry by mechanical stirring.

[0052] 2. Ball milling: place the suspended particle slurry prepared in step 1 in a planetary ball mill for mechanical ball milling, the ball-to-material ratio is 3:1, and the ball milling time is 30 hours to obtain a uniform composite of activator and FeAl-based alloy powder. Irregular energy storage powder.

[0053] 3. Sizing: Spray a layer of uniform FeAl pre-alloyed powder composite slurry on the 310S stainless steel m...

Embodiment 3

[0057] A method for preparing FeAl intermetallic compound flexible film by pre-alloy powder sintering method:

[0058] 1. Powder blending: add 10g of thermoplastic phenolic resin to 40mL of ethanol, then add 100g of FeAl aerosolized spherical alloy powder (wherein the aluminum content is 25wt.%, the balance is Fe), and then add a sintering activator (calculated by element, It contains 0.3g of boron and 0.3g of yttrium, added in the form of iron boron powder and yttrium boride); it is prepared into a uniform suspended particle slurry by mechanical stirring.

[0059] 2. Ball milling: Place the suspended particle slurry prepared in step 1 in a planetary ball mill for mechanical ball milling. The ball-to-material ratio is 3:1, and the ball milling time is 36 hours to obtain a uniform composite of activator and FeAl-based alloy powder. Irregular energy storage powder.

[0060] 3. Sizing: Spray a layer of uniform FeAl pre-alloyed powder composite slurry on the 310S stainless steel ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

| Median diameter | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com