Doping method and application of green bristlegrass-based bio-based carbon material

A bio-based carbon and foxtail technology, which is applied in the preparation/purification of carbon, non-aqueous electrolyte battery electrodes, electrical components, etc., can solve the problems of inaccurate heating program control, low doping rate, and high reaction temperature, and achieve reaction Effects of shortened time, high doping rate, and low reaction temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0061] The preparation method of Setaria bio-based fluorine microwave doped carbon material powder comprises the following preparation method:

[0062] (1) dry the foxtail bio-based carbon material in an oven to remove moisture;

[0063] (2) Put the dried foxtail bio-based carbon material and 40% hydrofluoric acid into the microwave reactor and stir, and feed inert gas N 2 , microwaved at 120°C for 7 hours to obtain a solution of Setaria bio-based fluorine microwave-doped carbon material;

[0064] (3) vacuum filtration is used to clean the solvent in the Setaria bio-based fluorine microwave-doped carbon material solution with deionized water to obtain the Setaria bio-based fluorine microwave-doped carbon material slurry;

[0065] (4) freeze-drying the bio-based fluorine microwave-doped carbon material slurry of Setaria chinensis to obtain the bio-based fluorine microwave-doped carbon material powder of Setaria chinensis.

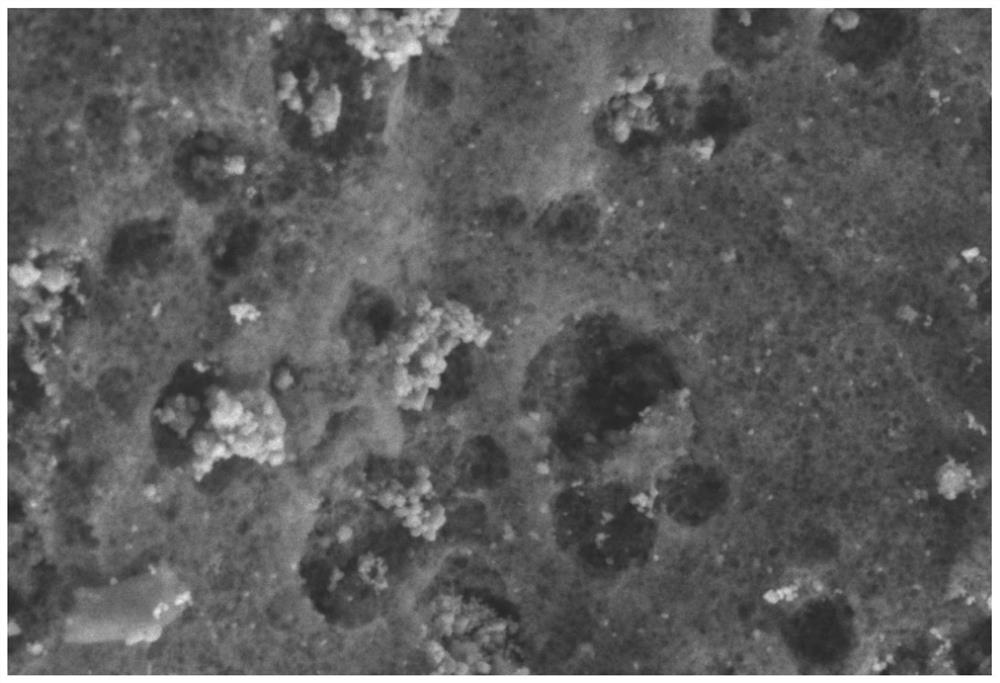

[0066] Scanning electron microscopy of the Setaria b...

Embodiment 2

[0077] The preparation method of Setaria bio-based nitrogen microwave doped carbon material powder comprises the following preparation method:

[0078] (1) dry the foxtail bio-based carbon material in an oven to remove moisture;

[0079] (2) After mixing the dried foxtail bio-based carbon material and urea at a mass ratio of 4:1, put them into a microwave reactor and stir, pass in an inert gas, and microwave at 120°C for 7 hours to obtain the green foxtail bio-based Nitrogen microwave doped carbon material solution;

[0080] (3) vacuum filtration is used to clean the solvent in the Setaria bio-based nitrogen microwave-doped carbon material solution with deionized water to obtain the Setaria bio-based nitrogen microwave-doped carbon material slurry;

[0081] (4) freeze-drying the bio-based nitrogen microwave-doped carbon material slurry of Setaria chinensis to obtain the bio-nitrogen microwave-doped carbon material powder of Setaria chinensis.

[0082] The yield of the Setari...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com