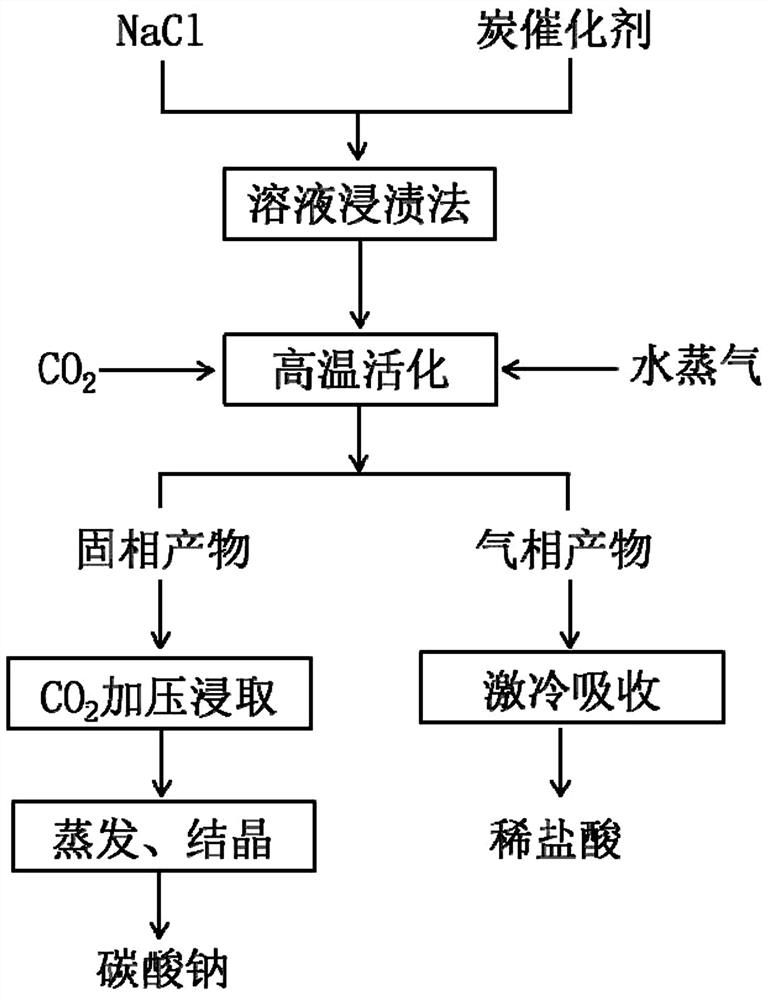

Method for preparing sodium carbonate and coproducing hydrochloric acid by sodium chloride catalytic thermal decomposition method

A technology of sodium chloride catalysis and thermal decomposition method is applied in the field of preparing sodium carbonate and co-producing hydrochloric acid, which can solve the problems of low preparation process efficiency, low utilization efficiency of sodium and chlorine atoms, and high energy consumption, and achieves simplified preparation process and technology, The effect of good additional economic benefits and good prospects for industrial application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] In this example, biomass activated carbon was used as the catalyst, 15 wt% NaCl was loaded onto the activated carbon by solution impregnation method, 500 g sample was placed in a tube furnace, the temperature was programmed to 550 °C, and CO 2 Catalytic activation with water vapor, stop heating after reacting for 30 min, measure the HCl content in the water after the gas phase product is quenched by water, and measure the HCl content in the water after the solid phase cooling 2 Hydrothermal pressure leaching to obtain Na 2 CO 3 solution, and then after heating, concentration and crystallization, Na 2 CO 3 products, the specific steps are as follows:

[0020] (1) NaCl was loaded onto the biomass activated carbon catalyst by solution impregnation method, and the NaCl loading was 15 wt%;

[0021] (2) Take a 500 g sample and place it in a tube furnace, raise the temperature to 550 °C at a heating rate of 10 °C / min, and mix water vapor and CO 2 Activated decomposition b...

Embodiment 2

[0026] In this example, Shenmu bituminous coal was used as a catalyst, and 10 wt% NaCl was loaded onto Shenmu bituminous coal by solution impregnation method, and 500 g of the sample was placed in a tube furnace, and the temperature was raised to 300 °C by program, and CO 2 Catalytic activation with water vapor, stop heating after reacting for 30 min, measure the HCl content in the water after the gas phase product is quenched by water, and measure the HCl content in the water after the solid phase cooling 2 Hydrothermal pressure leaching to obtain Na 2 CO 3 solution, and then after heating, concentration and crystallization, Na 2 CO 3 products, the specific steps are as follows:

[0027] (1) NaCl was loaded onto the Shenmu bituminous coal catalyst by solution impregnation method, and the NaCl loading was 10 wt%;

[0028] (2) Take a 500 g sample and place it in a tube furnace, raise the temperature to 500 °C at a heating rate of 10 °C / min, and mix water vapor and CO 2 The...

Embodiment 3

[0033] In this example, graphite is used as a catalyst, 10 wt% NaCl is loaded onto the graphite by solution impregnation method, 500 g of the sample is placed in a tube furnace, the temperature is programmed to 700 ° C, and CO 2 Catalytic activation with water vapor, stop heating after reacting for 30 min, measure the HCl content in the water after the gas phase product is quenched by water, and measure the HCl content in the water after the solid phase cooling 2 Hydrothermal pressure leaching to obtain Na 2 CO 3 solution, and then after heating, concentration and crystallization, Na 2 CO 3 product. Specific steps are as follows:

[0034] (1) NaCl was loaded onto the graphite catalyst by solution impregnation method, and the NaCl loading was 5 wt%;

[0035] (2) Take a 500 g sample and place it in a tube furnace, raise the temperature to 500 °C at a heating rate of 10 °C / min, and mix water vapor and CO 2 The NaCl-supported graphite was passed through for activated decompo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com