N-propyl acetate backing material treatment process

A technology of n-propyl acetate and treatment process, which is applied in the field of n-propyl acetate, can solve problems such as the difficult handling of base material, and achieve the effects of reducing production, prolonging service life, and increasing yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

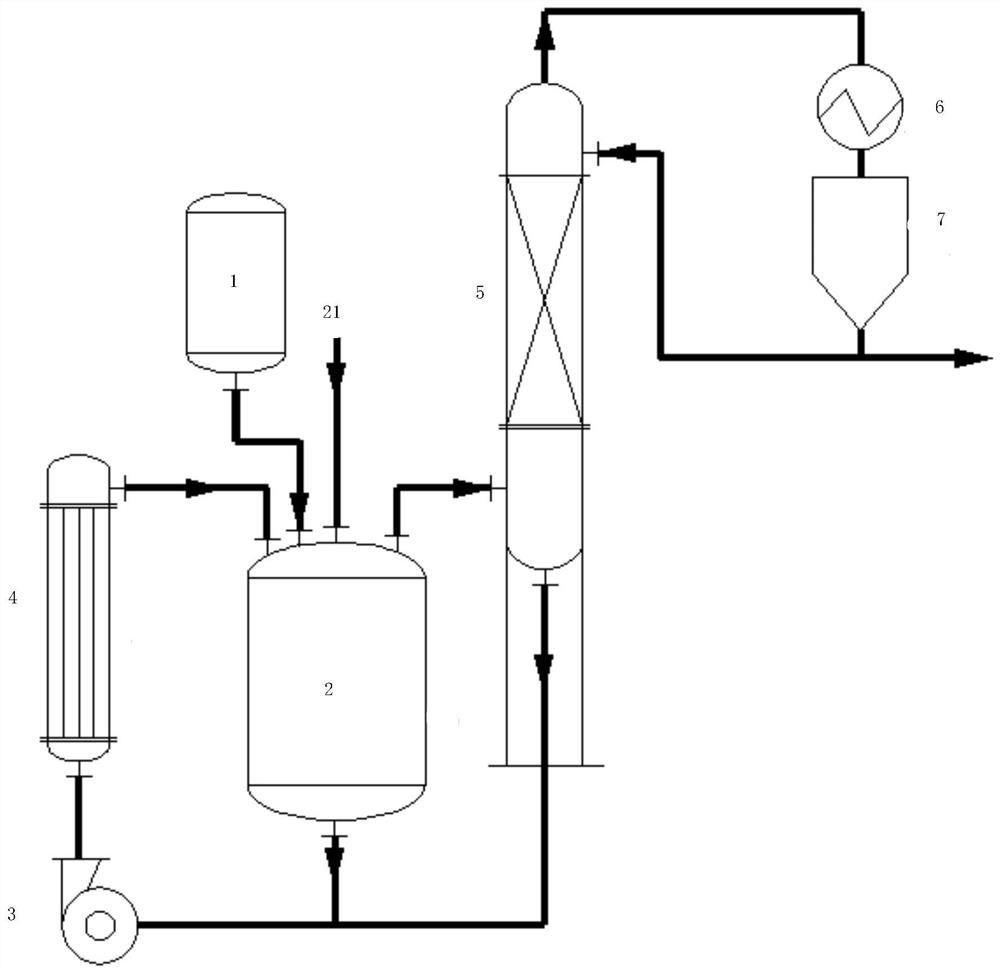

Method used

Image

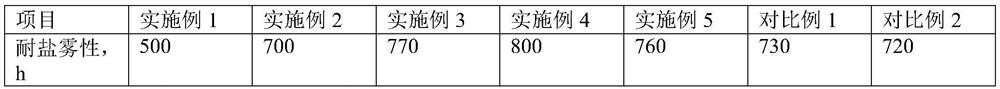

Examples

Embodiment 1

[0024] The preparation method of the anti-corrosion coating is as follows: first mix and disperse 30 parts of epoxy resin, 20 parts of solvent, and 1 part of dispersant evenly, then add 20 parts of filler to disperse evenly, and then add 0.5 parts of corrosion inhibitor benzotriazole to disperse evenly , to obtain anti-corrosion coatings.

Embodiment 2

[0026] The preparation method of the anti-corrosion coating is: (1) 0.5 parts of corrosion inhibitor benzotriazole, 10 parts of chitosan, 50 parts of curing agent and 10 parts of the solvent are mixed and dispersed uniformly;

[0027] (2) Mix and disperse 30 parts of epoxy resin, 20 parts of solvent and 1 part of dispersant evenly, then add 20 parts of filler to disperse evenly, and then add 0.5 parts of the product of step (1) to disperse evenly to obtain an anti-corrosion coating.

Embodiment 3

[0029] The preparation method of anti-corrosion coating is: (1) get the chitosan of molecular weight 3000, add the chlorobenzenemethane of 0.6eq and the potassium carbonate of 0.3eq, take DMF as solvent, react under heating reflux condition to obtain modified chitosan;

[0030] (2) 1 part of corrosion inhibitor benzotriazole, 20 parts of modified chitosan, 70 parts of curing agent and 20 parts of the solvent are mixed and uniformly dispersed;

[0031] (3) 30 parts of epoxy resin, 20 parts of solvent, and 1 part of dispersant were mixed and dispersed uniformly, then 20 parts of filler were added to disperse uniformly, and then 0.5 parts of the product of step (2) were added to disperse uniformly to obtain an anti-corrosion coating.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com