Raw material recovery device and method for preparing acyclovir intermediate diacetylguanine

A diacetylguanine and recovery method technology, which is applied in the field of raw material recovery equipment for the preparation of acyclovir intermediate diacetylguanine, can solve the problems of low yield, achieve high recovery rate, mild conditions, and less waste Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

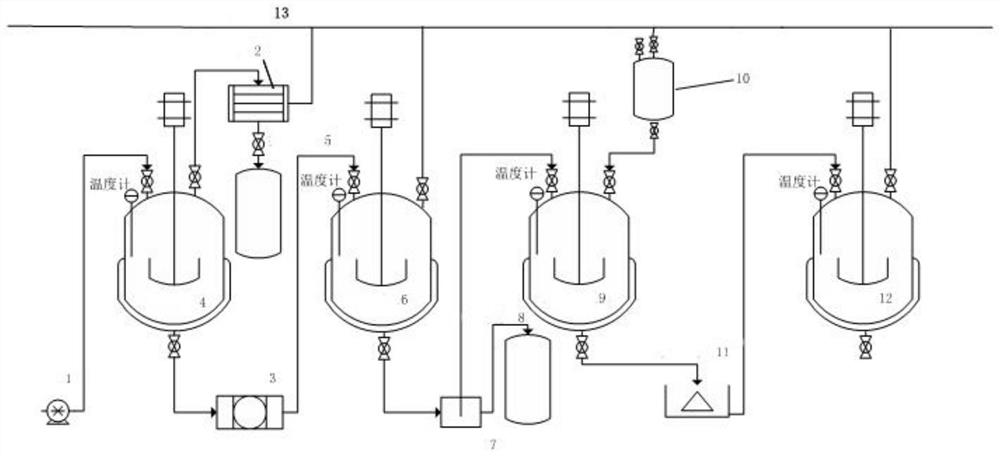

[0041] The structure of the reaction device is as figure 1. Using vacuum pump 1, a batch of mother liquor of diacetylguanine is transported to reaction kettle 4, and the solvent in the mother liquor is removed by concentration under reduced pressure at 50-100°C. The solvent is cooled to receiving tank 5 through condenser 2, and the waste gas is passed through the waste gas Pipe 13 discharges into the exhaust gas absorption unit. Transfer 250kg of hydrochloric acid (the molar ratio of diacetylguanine to hydrogen chloride is 1:7) and 250kg of water to the reaction kettle 4, and the reaction is complete at 50-100°C. After cooling to room temperature, add 1.88kg of D11 macroporous adsorption Resin (2%, the mass consumption of the adsorbent is 2% of the mass of the material to be recovered), after 2 hours, the feed liquid is separated by the pressure filter 3, and the liquid is transferred to the extraction kettle 6. 94kg of dichloromethane (the mass ratio of the extraction solve...

Embodiment 2

[0043] The structure of the reaction device is as figure 1 , using a vacuum pump 1 to transport a batch of mother liquor of diacetylguanine to the reaction kettle 4, and concentrate under reduced pressure at 50-100°C to remove the solvent in the mother liquor, and the solvent is cooled to the receiving tank 5 through the condenser 2, and the waste gas is passed through The exhaust gas pipe 13 discharges into the exhaust gas absorption device. Transfer 286kg (the molar ratio of diacetylguanine to hydrogen chloride is 1:8) of hydrochloric acid and 286kg of water to the reaction kettle 4 respectively, after the reaction is complete at 50-100°C, after cooling to room temperature, add 2.82kg of D11 macroporous Adsorption resin (the mass consumption of the adsorbent is 3% of the mass of the material to be recovered), the feed liquid is separated by the pressure filter 3 after 2 hours, and the liquid is transferred to the extraction kettle 6. 188kg of toluene (the mass ratio of the ...

Embodiment 3

[0045] The structure of the reaction device is as figure 1 , using a vacuum pump 1 to transport a batch of mother liquor of diacetylguanine to the reaction kettle 4, and concentrate under reduced pressure at 50-100°C to remove the solvent in the mother liquor, and the solvent is cooled to the receiving tank 5 through the condenser 2, and the waste gas is passed through The exhaust gas pipe 13 discharges into the exhaust gas absorption device. Transfer 322kg of hydrochloric acid (the molar ratio of diacetylguanine to hydrogen chloride is 1:9) and 322kg of water to the reaction kettle 4, after the reaction is complete at 50-100°C, after cooling to room temperature, add 4.70kg of D11 macroporous Adsorption resin (the mass consumption of the adsorbent is 5% of the mass of the material to be recovered), the feed liquid is separated by the pressure filter 3 after 2 hours, and the liquid is transferred to the extraction kettle 6. 376kg of ethyl acetate (the mass ratio of the extract...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com