Immobilized lipase as well as preparation method and application thereof in biodiesel

A technology of immobilized lipase and lipase, applied in the direction of immobilized on/in organic carriers, biochemical equipment and methods, biofuels, etc., can solve the problems of high acid value, long reaction time, and poor stability of biodiesel problem, achieve the effect of simple preparation method, low cost and good operation stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0049] Embodiment 1 prepares lipase MAS1-H108A

[0050] The preparation process of lipase MAS1-H108A is as follows:

[0051] (1) Activation of strains: Linearize the MAS1-H108A-pPICZαA-PDI plasmid, electroporate it into Pichia pastoris X33 competent, and screen out positive strains; Streak the Pichia pastoris X33 glycerol strain on YPD containing Zeocin Solid plate, cultivated in an incubator at 30°C for 60-75h;

[0052] (2) Preparation of primary seed liquid: inoculate the obtained single colony into a sterilized Erlenmeyer flask containing 50mL of YPD liquid medium, then place the Erlenmeyer flask at a temperature of 30°C and a shaking speed of 200rpm Shake culture in the bed for 18-24 hours to obtain the first-grade seed solution;

[0053] (3) Preparation of the secondary seed solution: Inject 5 mL of the primary seed solution into 100 mL of sterilized fresh YPD liquid medium, and shake and cultivate it in a shaker at 30° C. at a rotation speed of 200 rpm for 24 hours;

...

Embodiment 2

[0056] Example 2 Preparation of immobilized lipase MAS1-H108A

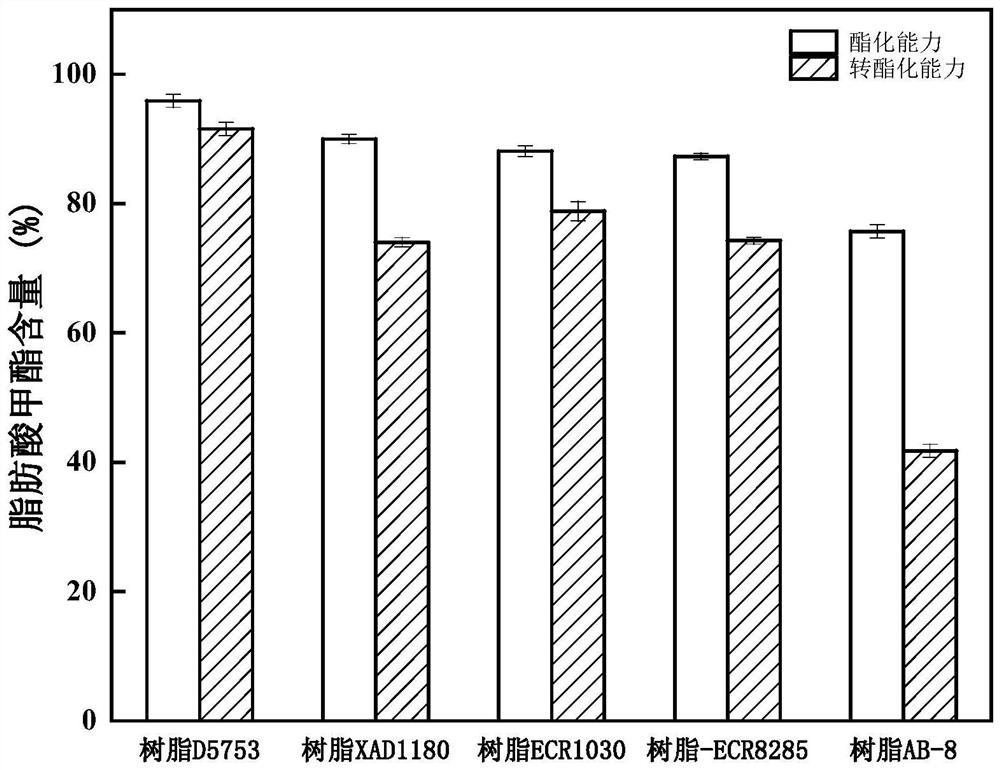

[0057] Lipase MAS1-H108A and resin D5753 (pore size 200-350nm, ultra-large pore size, purchased from Purite Company), Lifetech TM ECR1030M (pore diameter 22-34nm, mesoporous resin, purchased from Brilliant Company), Lifetech TM ECR8285 (aperture 45-65nm, macroporous resin, purchased from Brilliant Company), AMBERLITE TM XAD TM 1180N (pore diameter 30-55nm, mesoporous resin, purchased from Dow Company), AB-8 (pore diameter 13-14nm, mesoporous resin, purchased from Tianjin Jinda Resin Factory) was immobilized. After the fermentation broth was centrifuged and concentrated, 20 mL of phosphate buffer was added to 100 mL of enzyme liquid to adjust the pH to 7; and the carrier was added according to the ratio of 10,000 U / g of total enzyme activity / carrier, and mixed with the enzyme liquid for 8 hours. The immobilized enzyme was suction filtered using a Buchner funnel, the immobilized enzyme was washed with phosphate b...

Embodiment 3

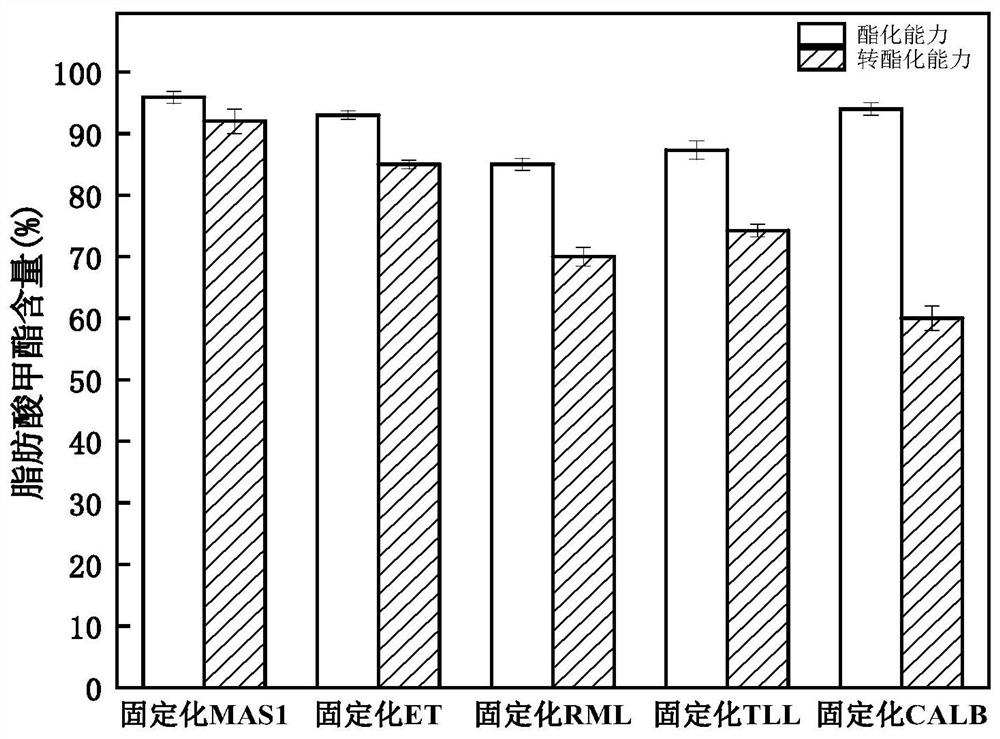

[0059] Example 3 Preparation of immobilized enzymes using resin D5753 and different lipases

[0060] Five lipases were selected: lipase MAS1-H108A (abbreviated as MAS1), CALB (derived from Candidaantarctica), Eversa Transform 2.0 (abbreviated as ET), RML (derived from Rhizomucor miehie), TLL (derived from Thermomyces lanuginosus), and Resin D5753 (pore size 200-350nm, ultra-large pore size) was combined to prepare 5 kinds of immobilized enzymes. The immobilization method is to add 20% phosphate buffer solution to the enzyme solution, adjust the pH to 8; add the carrier according to the ratio of 10,000U / g total enzyme activity / carrier, mix and stir with the enzyme solution for 8 hours, and use the Buchner funnel to immobilize Suction filter the immobilized enzyme, wash the immobilized enzyme with phosphate buffer until no protein exists in the filtrate, drain the immobilized enzyme and dry it at 40°C for 6 hours. Immobilized lipase can be prepared.

[0061] The esterification...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com