Method for preparing TixNy coating in situ by utilizing molten salt disproportionation reaction and product with TixNy coating

A technology of disproportionation reaction and in-situ preparation, which is applied in the direction of coating, metal material coating process, liquid chemical plating, etc., can solve the problems of metal nitride coating reporting and other problems, achieve long service life, simple preparation process steps, easy-to-achieve effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

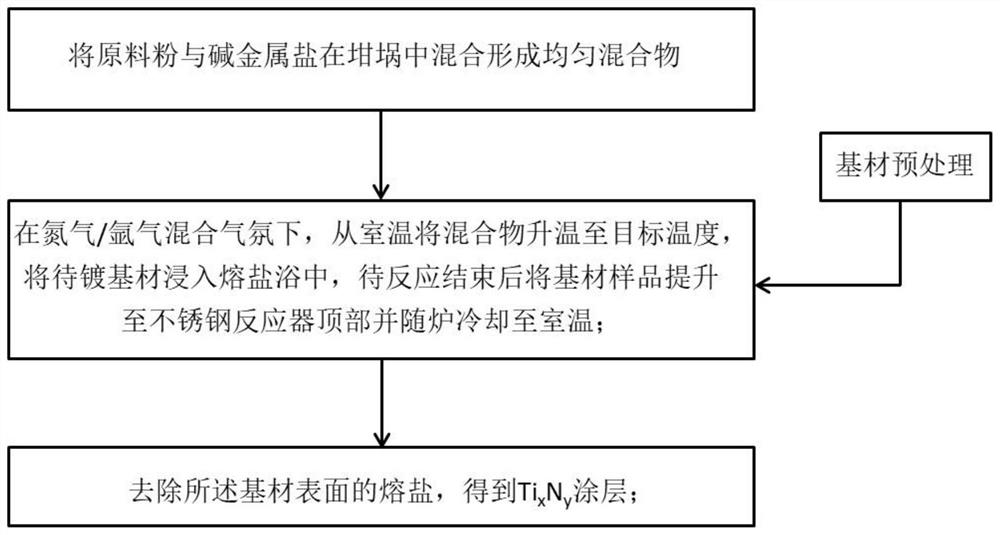

[0032] Example 1: This example provides an in-situ preparation of Ti by molten salt disproportionation reaction x N y coating method, see figure 1 , which includes the following steps:

[0033] (1) Pretreatment of substrate

[0034] Metal nickel, ferritic stainless steel, austenitic stainless steel and titanium alloy are selected as the substrate to be plated. However, the present invention includes but is not limited to the above-mentioned metals or alloy materials, as for other metals or alloy materials, as long as they are not dissolved in the molten salt system.

[0035] The substrate was pretreated, and all samples were mechanically polished with 240#, 600# and 1000# SiC sandpaper in sequence, and then ultrasonically cleaned with water, acetone and absolute ethanol, respectively, and dried for later use.

[0036] (2) to form a mixture

[0037] Mix the elemental titanium and the titanium compound with the alkali metal salt uniformly in a crucible to obtain a mixture. ...

Embodiment 2

[0052] Embodiment 2: In this embodiment, weigh 50 units of weight (for example, kilograms) of NaCl-KCl eutectic salt, and mix with 2 units of weight of Ti powder (300 mesh), 4 units of weight of K 2 TiF 6 Mix well in a graphite crucible. The above-mentioned graphite crucible was placed at the bottom of the closed reactor, and the 316L stainless steel substrate was suspended at the position where the compound was separated from the reactor. A mixture of nitrogen and argon was fed into the reactor, wherein the proportion of nitrogen was 20%. After heating up to 900°C at a rate of 8°C / min and stabilizing for 20 minutes, immerse the 316L stainless steel substrate in the molten compound and keep it at this temperature for 3 hours, then slowly lift the 316L stainless steel substrate into the reactor to get out of the melt The position of the compound in the state and cooled to room temperature with the furnace. The 316L stainless steel substrate was taken out and ultrasonically c...

Embodiment 3

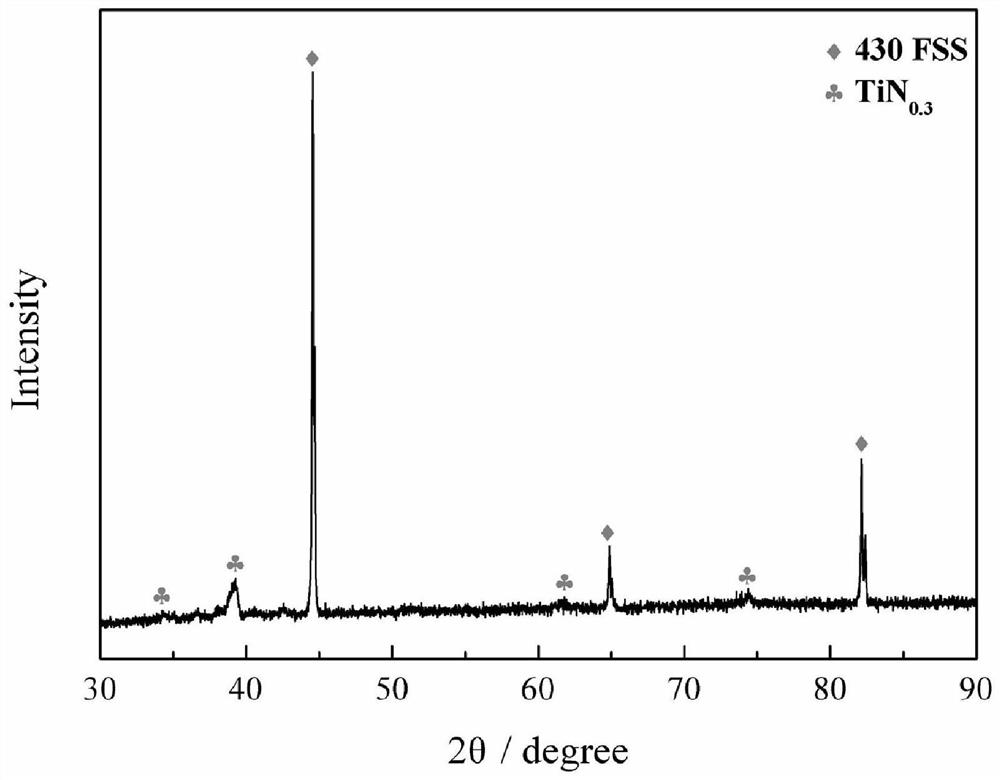

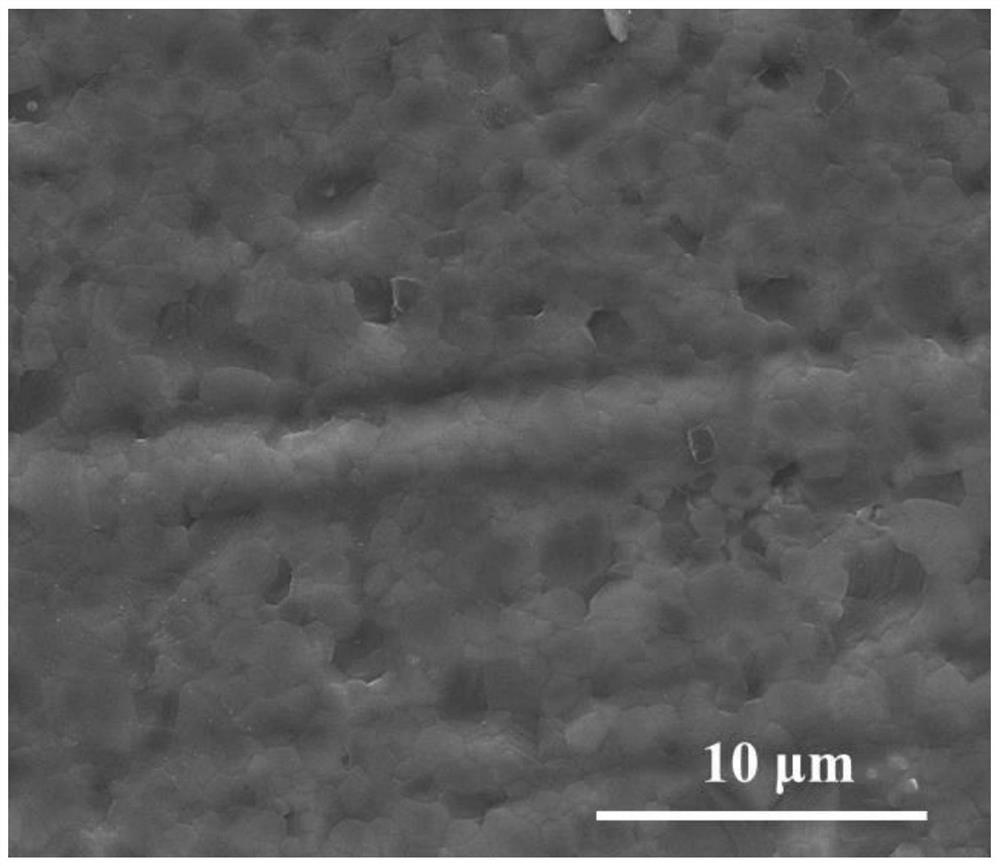

[0054] Embodiment 3: In this embodiment, weigh 20 units of weight (for example, kilograms) of NaCl-KCl eutectic salt, and mix with 0.5 units of weight of Ti powder, 1.5 units of weight of K 2 TiF 6 Mix well in a graphite crucible. The above-mentioned graphite crucible is placed at the bottom of the closed reactor, and the 430 stainless steel substrate is suspended in the position where the compound is separated from the reactor. A mixture of nitrogen and argon is introduced into the reactor, the ratio of nitrogen is 12%, the temperature is raised to 800°C at a rate of 10°C / min and stabilized for 20 minutes, then the 430 stainless steel substrate is immersed in the molten compound for 2 Hour. After the deposition, the 430 stainless steel substrate was slowly lifted to the position where the molten compound was separated from the reactor and cooled to room temperature with the furnace. After the 430 stainless steel substrate was taken out, it was ultrasonically cleaned with w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com