Addition type multi-component copolymerized phenyl silicone rubber and preparation method thereof

A technology for copolymerizing phenyl and silicone rubber, which is applied in the field of addition-type multi-component copolymerized phenyl silicone rubber and its preparation, can solve the problems of long reaction time, cumbersome operation process, cumbersome process, etc., and achieve the optimization of product post-treatment process, The effect of high conversion rate of raw materials and short reaction time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] Take the following components respectively in parts by weight (grams):

[0032] (1) Preparation for synthesis

[0033] Take 1.5 times the amount of the initiator required before the reaction, put it into a beaker, place it in a vacuum drying oven at 0.1Mpa, dry it at 40°C for 2 hours, and put it in a desiccator for later use. Clean the glass equipment and place it in a blast drying oven Store at 100°C, and return to room temperature naturally after 0.5h for later use.

[0034] (2) Synthesis process

[0035] In step (1) reactor, add 16 parts of octamethylcyclotetrasiloxanes (D 4 ), 16 parts of methylphenylcyclotetrasiloxane (D 4 ph ) and 8 parts of methyltrifluoropropylcyclotrisiloxane (D 3 F ), and then heated up to 42 ° C, while pumping vacuum while blowing N 2 Or while stirring, in order to improve the dehydration efficiency, the duration is 1.5h. Then in N 2 The catalyst tetramethylammonium hydroxide is added under the atmosphere, and the dosage is 0.1 parts...

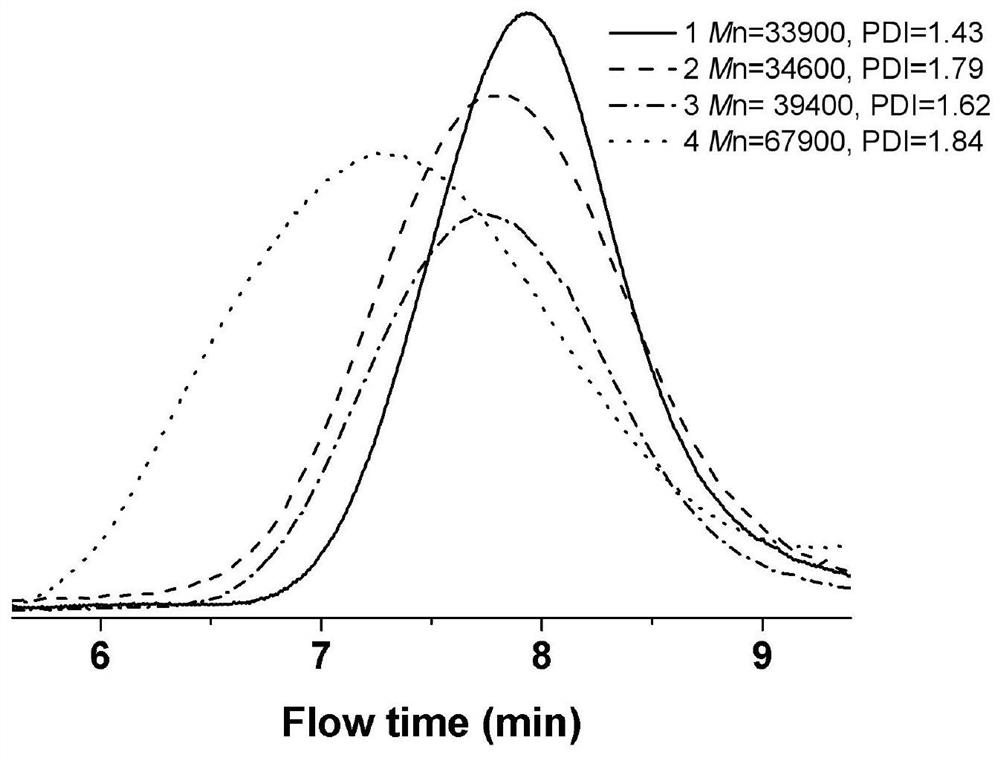

Embodiment 2-4

[0039] The experimental procedure is the same as that of Example 1, and the addition-type multi-component copolymerized phenyl silicone rubbers of Examples 2-4 with different mass ratios were synthesized according to the formula in Table 1.

[0040] Table 1

[0041]

[0042] Structure Characterization

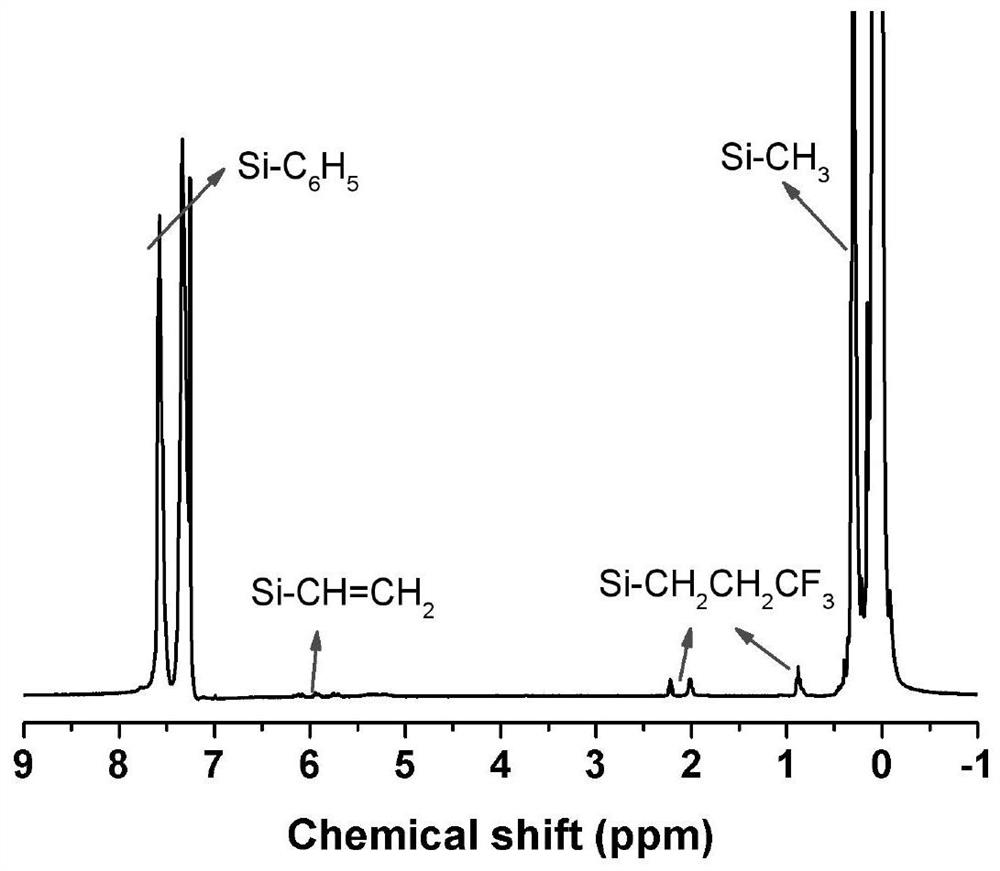

[0043] (1) 1 H-NMR characterization

[0044] Carry out proton nuclear magnetic resonance spectrum analysis (as figure 1 ), to get the following structure:

[0045]

[0046] In the formula, m is the number of dimethylsiloxane chains, n is the number of methylphenylsiloxane chains, and p is the number of methyltrifluoropropylsiloxane chains. Si-C at δ=7.32-7.52 6 h 5 The integrated area of the peak is denoted as a, Si-CH at δ=2.01-2.22 2 CH 2 CF 3 The integrated area of the peak is denoted as b, Si-CH at δ = 0-0.5 3 The integrated area of the peak is denoted as c. Obtain following formula according to methylphenyl trifluoropropyl structural formula:

[004...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com