Simple preparation method of honeycomb porous carbon with high specific surface area

A high specific surface area, honeycomb technology, applied in the preparation/purification of carbon, etc., can solve the problems of high production cost, difficult pore making, complicated process, etc., and achieve the effect of low cost and large-scale production and application.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] Add 100mL glycerin and 2.5g zinc acetate to a 250mL round bottom flask, heat to reflux at 150°C for 2h, collect the white solid precipitate, wash with ethanol three times, and dry in vacuum to obtain the organic complex powder.

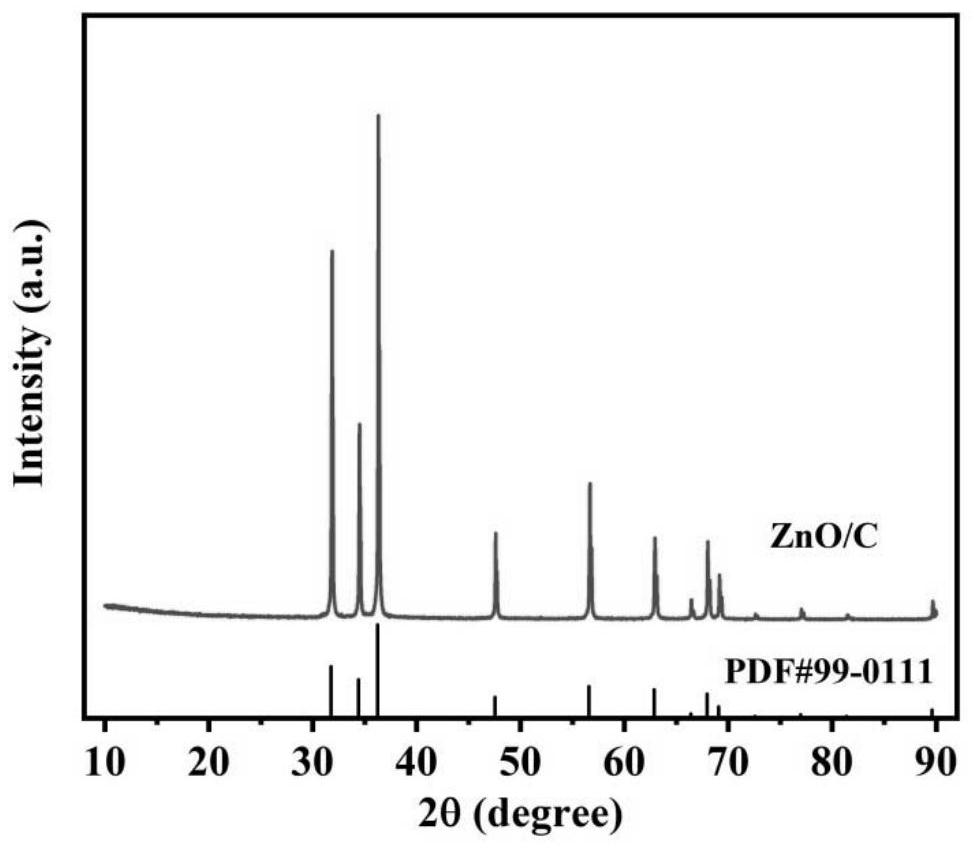

[0037] The obtained product was placed in a tube furnace, under the protection of nitrogen, treated at a high temperature of 800°C for 1 hour, and after natural cooling and light grinding, a mixture powder of black porous carbon and ZnO was obtained. From the XRD test results, it can be seen that the characteristic peak of ZnO is obvious, and compared with the standard card (#99-0111) has the same characteristic peaks ( figure 1 ).

[0038] The above powder is added to dilute hydrochloric acid solution and stirred to remove the hard template, washed with water until neutral and then dried to obtain honeycomb porous carbon.

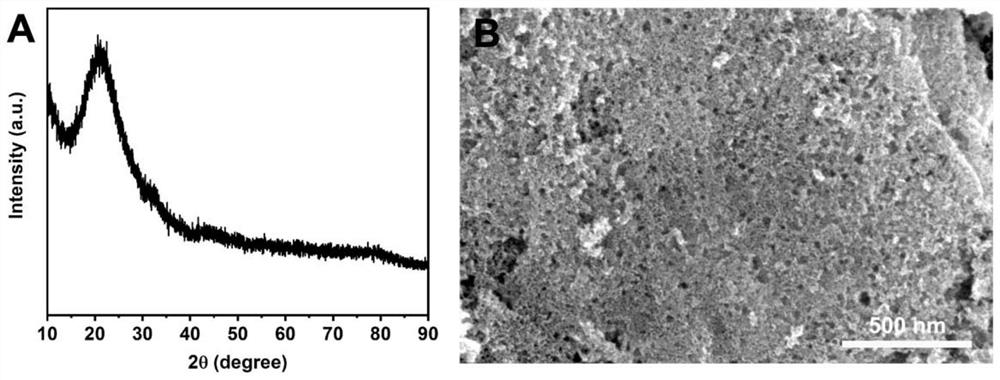

[0039] X-ray diffractometer and scanning electron microscope were used to characterize the material, and it was found th...

Embodiment 2

[0042] Weigh 4.2g of zinc acetate into an autoclave, add 100mL of glycerin, stir to dissolve, keep solvothermal reaction at 150°C for 1h, centrifuge and wash with alcohol to obtain a white precipitate.

[0043] Under the protection of nitrogen, the obtained product was subjected to high temperature treatment at 600° C. for 2 hours, and a mixture of porous carbon and zinc oxide was obtained after grinding.

[0044] The above mixture was added into dilute hydrochloric acid solution for ultrasonic dispersion, stirred overnight, washed with water until neutral, and dried to obtain honeycomb porous carbon with high specific surface area.

[0045] Figure 4 As shown, the obtained porous carbon has a rich pore structure, and it can be seen from the enlarged scanning electron microscope that the pores are evenly distributed throughout the carbon body structure, showing a honeycomb shape.

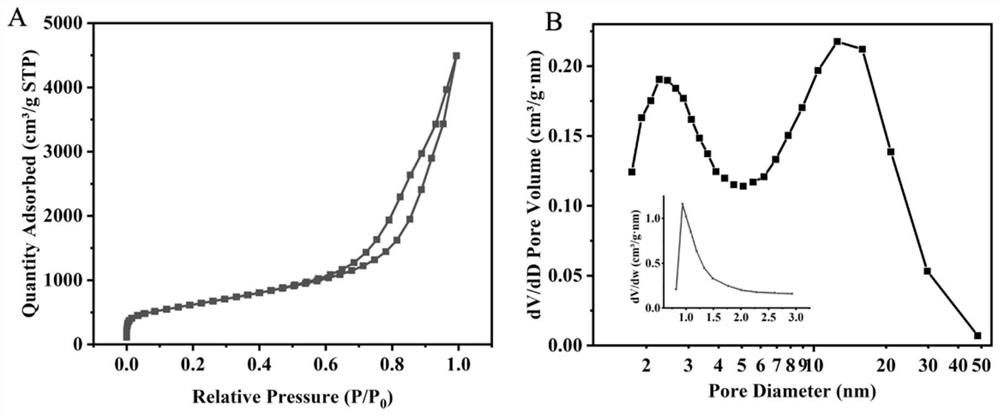

[0046] Figure 5 It is the nitrogen adsorption-desorption curve and pore size distribution dia...

Embodiment 3

[0048] Weigh 5.9g of zinc acetate and place it in a round bottom flask, add 100mL of glycerin to stir the reaction, and keep the reaction at reflux at 120°C for 5h. The precipitate after the reaction was collected, washed with centrifuged alcohol and dried to obtain the organic complex.

[0049] Put the above solid in a tube furnace for vacuum calcining, keep it at 900°C for 3 hours to obtain a black solid, which is zinc oxide and porous carbon, add dilute hydrochloric acid after grinding to remove the hard template, wash with water until neutral, and dry the final black solid in vacuum to obtain Honeycomb porous carbon.

[0050] From Figure 6 It can be seen from the TEM image that the porous carbon pores in this embodiment are very rich, and there are a large number of pores of about 10-20nm uniformly distributed in the entire carbon body structure, and the pore walls are relatively thin. Figure 7 The mesoporous pore size distribution of the porous carbon obtained in this...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com