Gel electrolyte precursor and application thereof

A gel electrolyte and precursor technology, applied in solid electrolytes, non-aqueous electrolytes, electrolyte immobilization/gelation, etc., can solve the problems of high cost, complex preparation process, insufficient rate performance and cycle performance, etc. Elasticity and porosity, improving safety performance, and ensuring the effect of rate performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

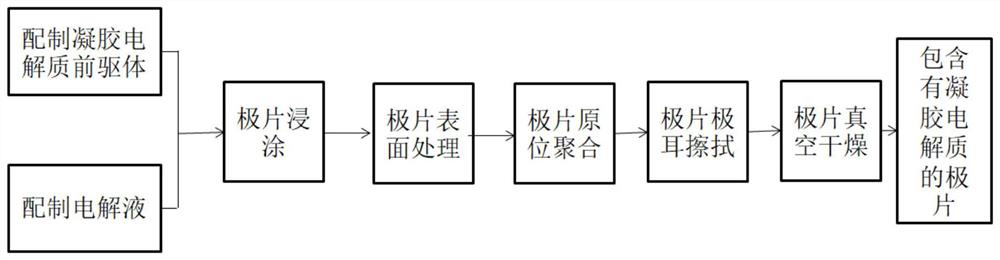

[0093] The schematic diagram of the preparation process of the pole piece comprising the gel electrolyte in the present invention is as follows figure 1 shown by figure 1 It can be seen that the process includes the following steps:

[0094] (a) preparing gel electrolyte precursor and electrolyte;

[0095] (b) mixing the gel electrolyte precursor and electrolyte to obtain a mixed solution, and placing the mixed solution in an aluminum-plastic film;

[0096] (c) pole piece is vertically placed in the aluminum-plastic film of step (b) and carries out pole piece dip-coating;

[0097] (d) Surface treatment of the pole piece after dipping, that is, wipe the surface of the pole piece with dust-free paper;

[0098] (e) re-place the pole piece in the step (d) in a new aluminum-plastic film for in-situ polymerization;

[0099] (f) wiping the tabs of the pole pieces after in-situ polymerization;

[0100] (g) Vacuum-drying the pole piece in step (f) to obtain a pole piece containing...

Embodiment 1

[0102] In this embodiment, the gel electrolyte precursor contains the following components: gel skeleton monomer, flexible additive, crosslinking agent, polymerization initiator and lithium salt;

[0103] Wherein, the gel skeleton monomer is vinylene carbonate;

[0104] The flexible additive is polyethylene glycol methacrylate with a molecular weight of 3500;

[0105] The crosslinking agent is 1.6 hexanediol diacrylate;

[0106] The polymerization initiator is azobisisobutyronitrile;

[0107] The lithium salt is lithium bistrifluoromethanesulfonylimide.

[0108] Based on the sum of the molar weights of gel skeleton monomers, flexible additives, crosslinking agents and polymerization initiators as 100%, the gel electrolyte precursor includes the following components:

[0109]

[0110] The ratio of the molar weight of the lithium salt to the volume of the gel skeleton monomer is 0.5mol / L;

[0111] The composition of the electrolyte: the solvent is the volume ratio EC:DMC:...

Embodiment 2

[0130] The difference between this embodiment and Example 1 is that, based on the sum of the molar weights of the gel skeleton monomer, flexible additive, crosslinking agent and polymerization initiator as 100%, the gel electrolyte precursor includes the following components:

[0131]

[0132]

[0133] The ratio of the molar weight of the lithium salt to the volume of the gel skeleton monomer is 2mol / L;

[0134] Other parameters and conditions are exactly the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com