Weather-resistant halogen-free flame-retardant light-diffusion PC/PBT material for charging pile panel and preparation method thereof

A charging pile and light diffusion technology, applied in the field of polymer materials, can solve the problems of poor mechanical properties and processability, low flame retardancy, poor weather resistance, etc., and achieve good processability, improved flame retardancy, and high transparency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

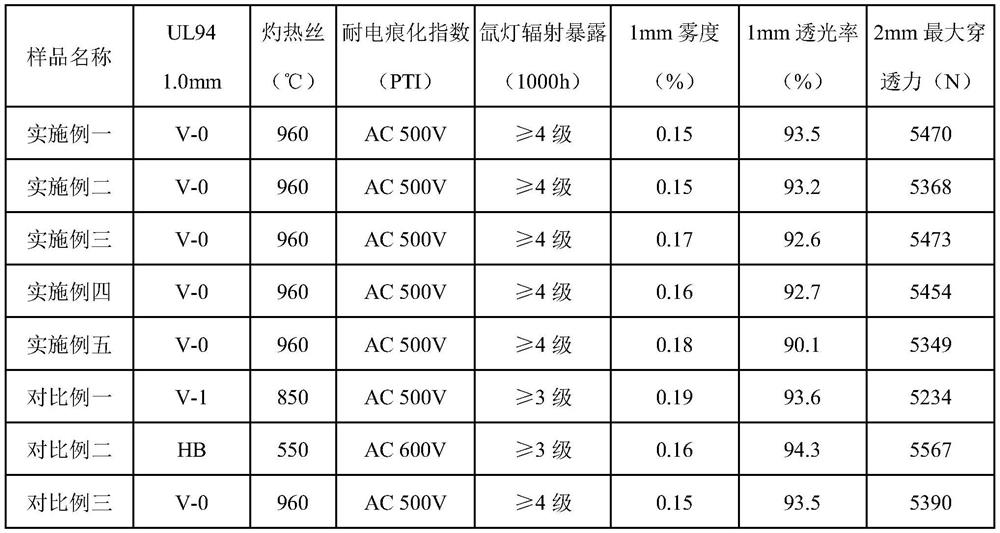

Examples

preparation example Construction

[0034] A method for preparing a weather-resistant halogen-free flame-retardant light-diffusing PC / PBT material for a charging pile panel of the present invention comprises the following steps:

[0035] 1) Take high-viscosity polycarbonate, polybutylene terephthalate and methylphenylsiloxane, mix and stir to obtain a mixture, and set aside;

[0036] 2) Take a toughening agent, an antioxidant, an ultraviolet absorber, a light stabilizer, an aldehyde inhibitor, and a light diffusing agent, and add them to the mixture obtained in step 1), and stir to obtain a mixture;

[0037] 3) Put the mixture obtained in step 2) into a twin-screw extruder for extrusion. The extruder temperature zone temperature is: 235-245°C for the first stage, 255-265°C for the second stage, 260-270°C for the third stage, and 260-270°C for the fourth stage. 245-255°C, five stages 245-255°C, six stages 255-265°C, seven stages 255-260°C, eight stages 245-260°C, nine stages 245-260°C, ten stages 245-260°C, eleve...

Embodiment 1

[0040] A method for preparing a weather-resistant halogen-free flame-retardant light-diffusing PC / PBT material for a charging pile panel of the present invention comprises the following steps:

[0041] 1) Weigh raw materials according to the following parts by weight: 78 parts of high-viscosity polycarbonate, 10 parts of low-viscosity PBT, 10 parts of bisphenol A bis(diphenyl phosphate), 0.7 part of methylphenylsiloxane, transparent Toughening agent low molecular weight polyolefin 0.8 parts, antioxidant β-(3,5-di-tert-butyl-4-hydroxyphenyl) octadecyl propionate 0.2 parts, tris[2,4-di-tert-butyl 0.2 part of phenyl]phosphite antioxidant, 0.15 part of UV absorber 2,2'methylene-(6-(2H-benzotriazole)-4-tert-octyl)phenol, neutral hindered amine light 0.15 parts of stabilizer, 0.5 parts of fatty acid ester mixture aldehyde inhibitor, 0.8 parts of light diffusing agent EXM-5;

[0042] 2) Take high-viscosity polycarbonate, low-viscosity PBT and methylphenylsiloxane, put high-viscosity...

Embodiment 2

[0046] A method for preparing a weather-resistant halogen-free flame-retardant light-diffusing PC / PBT material for a charging pile panel of the present invention comprises the following steps:

[0047] 1) Weigh the raw materials according to the following parts by weight: 82 parts of high-viscosity polycarbonate, 8 parts of low-viscosity PBT, 8 parts of bisphenol A bis(diphenyl phosphate), 0.6 part of methylphenylsiloxane, transparent Toughener 0.8 parts of low molecular weight polyolefin, β-(3,5-di-tert-butyl-4-hydroxyphenyl) n-octadecyl propionate antioxidant 0.2 parts, tris[2,4-di-tert-butyl 0.2 parts of phenyl]phosphite antioxidant, 0.15 parts of UV absorber 2,2'methylene-(6-(2H-benzotriazole)-4-tert-octyl)phenol, neutral hindered amine 0.15 part of light stabilizer, 0.5 part of fatty acid ester mixture aldehyde inhibitor, 0.8 part of light diffusing agent EXM-5;

[0048] 2) Take high-viscosity polycarbonate, low-viscosity PBT and methylphenylsiloxane, put high-viscosity ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity coefficient | aaaaa | aaaaa |

| Viscosity coefficient | aaaaa | aaaaa |

| Viscosity coefficient | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com