Radiation-proof breathable antibacterial fabric

An antibacterial fabric and anti-radiation technology, applied in the field of textile fabrics, can solve the problems of many raw materials, high price, and limited use range, etc., and achieve the effects of good skin affinity, not easy to delaminate, high production efficiency and yield rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

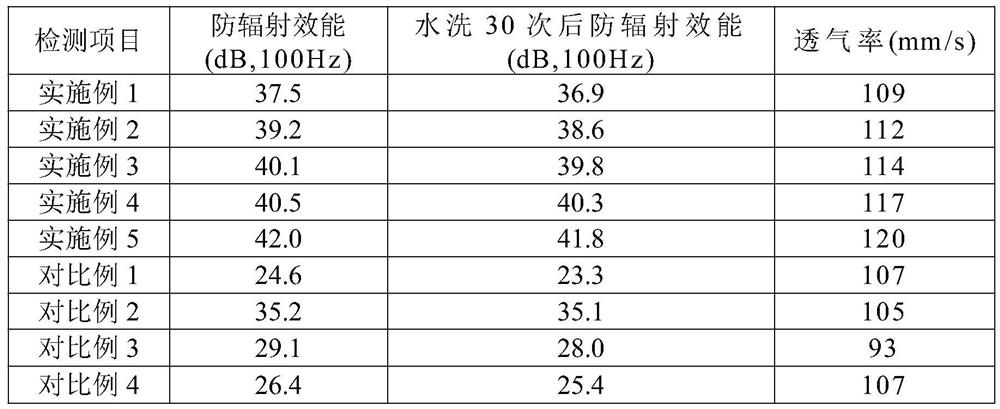

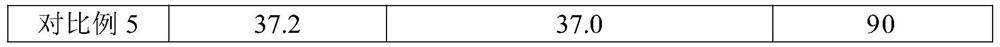

Examples

Embodiment 1

[0041] A radiation-proof, breathable and antibacterial fabric, characterized in that it comprises a base fabric layer and a weather-resistant and breathable functional layer arranged on the base fabric layer; the base fabric layer is woven from warp yarns and weft yarns; the warp yarns are nano silver-modified Graphene fiber; the weft yarn is a functional synthetic fiber; the functional synthetic fiber is made from the following raw materials in parts by weight: 10 parts of carboxyl-terminated hyperbranched polyester, 50 parts of polyester chips, cationic modified hydroxylation 1 part of fullerene, 2 parts of graphene-coated nano-aluminum powder, and 1 part of coupling agent; the coupling agent is silane coupling agent KH550.

[0042] The preparation method of the cationic modified hydroxylated fullerene comprises the following steps:

[0043] Step D1. Add bis(2-hydroxyethyl)amino(trimethylol)methane and chloroalkyltriethoxysilane into the organic solvent, stir and react at 40...

Embodiment 2

[0056] A radiation-proof, breathable and antibacterial fabric, characterized in that it comprises a base fabric layer and a weather-resistant and breathable functional layer arranged on the base fabric layer; the base fabric layer is woven from warp yarns and weft yarns; the warp yarns are nano silver-modified Graphene fiber; the weft yarn is a functional synthetic fiber; the functional synthetic fiber is made from the following raw materials in parts by weight: 13 parts of carboxyl-terminated hyperbranched polyester, 55 parts of polyester chips, cationic modified hydroxylation 1.5 parts of fullerene, 2.5 parts of graphene-coated nano-aluminum powder, and 1.5 parts of coupling agent; the coupling agent is silane coupling agent KH560.

[0057] The preparation method of the cationic modified hydroxylated fullerene comprises the following steps:

[0058] Step D1. Add bis(2-hydroxyethyl)amino(trimethylol)methane and chloroalkyltriethoxysilane into the organic solvent, stir and rea...

Embodiment 3

[0072] A radiation-proof, breathable and antibacterial fabric, characterized in that it comprises a base fabric layer and a weather-resistant and breathable functional layer arranged on the base fabric layer; the base fabric layer is woven from warp yarns and weft yarns; the warp yarns are nano silver-modified Graphene fiber; the weft yarn is a functional synthetic fiber; the functional synthetic fiber is made from the following raw materials in parts by weight: 15 parts of carboxyl-terminated hyperbranched polyester, 60 parts of polyester chips, cationic modified hydroxylation 2 parts of fullerene, 3.5 parts of graphene-coated nano-aluminum powder, and 2 parts of coupling agent; the coupling agent is silane coupling agent KH570.

[0073] The preparation method of the cationic modified hydroxylated fullerene comprises the following steps:

[0074] Step D1, adding bis(2-hydroxyethyl)amino(trimethylol)methane and chloroalkyltriethoxysilane into an organic solvent, stirring and r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com