High-oxygen drinking water production process and system based on gas nanocrystallization technology

A high-oxygen drinking water and production process technology, applied in the direction of degassed water/sewage treatment, water/sewage treatment, chemical instruments and methods, etc., can solve the problems of unsuitability for large-scale industrial production, unevenness, and high cost, and achieve Achieve large-scale continuous production, uniform oxygen nanobubbles, and small oxygen nanobubbles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

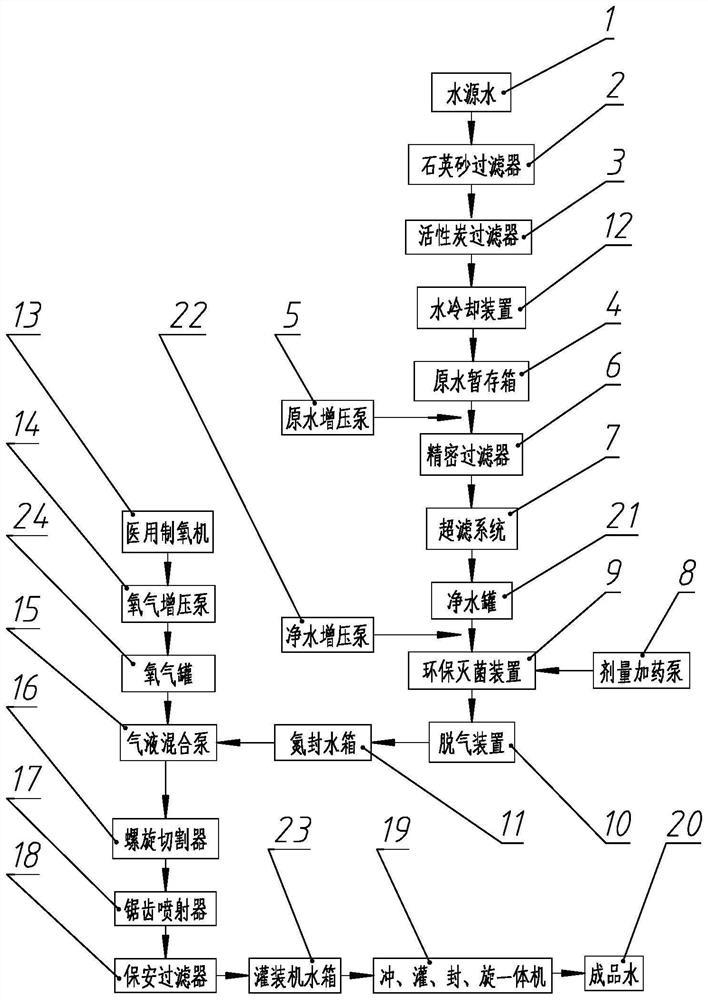

[0033] The high-oxygen drinking water production process based on the gas nanotechnology provided by this embodiment includes the following steps:

[0034] (1) The source water is filtered through the quartz sand filter and the activated carbon filter in sequence, and then enters the water cooling device for cooling and cooling. The cooled water is stored in the raw water temporary storage tank. After the stored water is raised by the raw water booster pump, the water pressure is The water in the water purification tank is sterilized by the environmental protection sterilization device and then enters the degassing device for degassing, and the degassed water is stored in the nitrogen-sealed water tank;

[0035] (2) The medical grade oxygen produced by the medical oxygen generator is sent into the oxygen tank through the oxygen booster pump;

[0036] (3) Mix the water in the nitrogen-sealed water tank and the oxygen in the oxygen tank in the gas-liquid mixing pump and then ent...

Embodiment 2

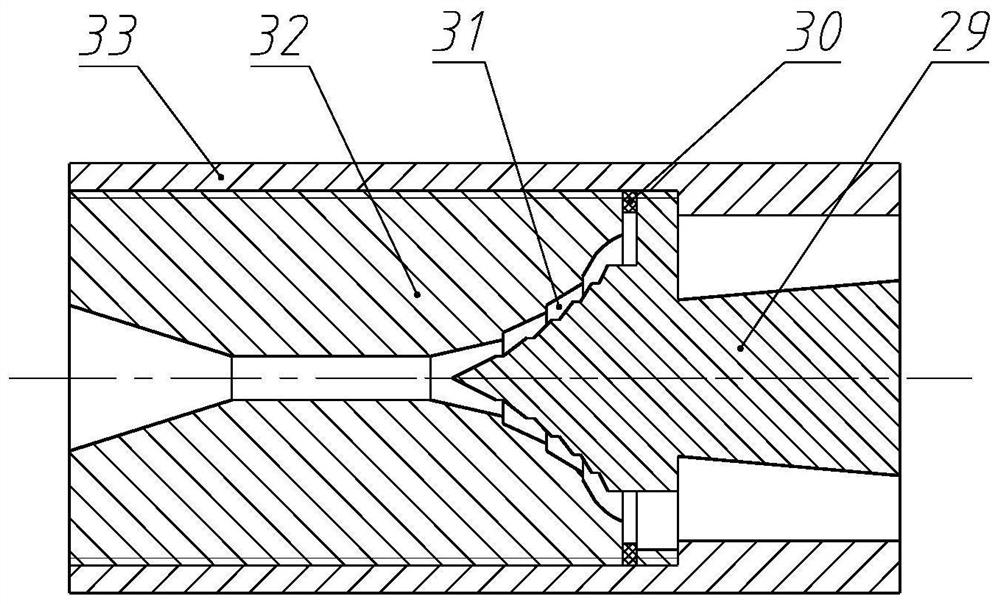

[0045] Such as Figure 1~2 , the present embodiment provides a high-oxygen drinking water production system based on gas nanotechnology, which includes sequentially connected quartz sand filter 2, activated carbon filter 3, water cooling device 12, raw water temporary storage tank 4, precision filtration device 5, ultrafilter 7, water purification tank 21 and environmental protection sterilization device 9, the raw water temporary storage tank 4 is also connected to the raw water booster pump 5, and the raw water booster pump 5 is connected to the precision filter 6, and the environmental protection The sterilizing device 9 is connected to the degassing device 10, the nitrogen-sealed water tank 11 and the gas-liquid mixing pump 15 in turn, and the environmental protection sterilizing device 9 is also connected to the dosage dosing pump 8, and the gas-liquid mixing pump 15 is connected to the spiral cutter 16, Sawtooth injector 17 and security filter 18, the gas-liquid mixing p...

Embodiment 3

[0049] A high-oxygen drinking water production process based on gas nanotechnology, using the helical cutting thinning of the static spiral cutter, the small gap sawtooth cutting thinning of the sawtooth cutting injector, nano-bubble generation technology and modern liquid nitrogen sealing technology; The source is a medical oxygen generator, the model of the oxygen generator is SND-3Y, and the oxygen output is 3 m 3 / h, the oxygen flow rate is 12L / min, the oxygen pressure at the outlet of the oxygen tank is 0.5MPa; the inner diameter of the cutting chamber of the spiral cutter is φ40mm; the water flow rate is 3m 3 / h, the water flow cutting line speed is 1.3m / s; the rated flow rate of the gas-liquid mixing pump is 3.5 m3 / h, and the head is 40 meters; Polluted, pure natural groundwater.

[0050] Filtration system: coarse filtration of quartz sand filter, model ZX-SY800, processing flow rate of 5 cubic meters per hour; activated carbon filter model KA-1, processing flow rate o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com