A kind of composite core material and its preparation method and application

A composite core and membrane technology, applied in applications, other household appliances, machinery and equipment, etc., can solve the problems of unsuitable large-area building insulation materials, slowing down the flow of water flow, and high rebound rate of vacuum insulation panels. The production process is short, the effect of preventing collapse and uniform density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0047] The preparation method of fiber / powder composite core material comprises the steps:

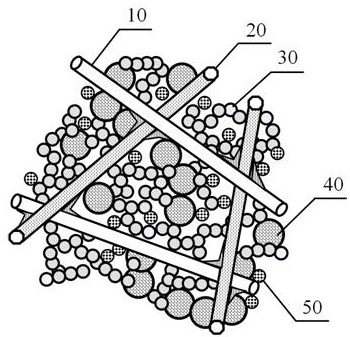

[0048] (1) Mixing of fiber and powder: chopped glass fiber 10 (average diameter 11 μm, average length 6 mm), low melting point nylon fiber 20 (full melting type, initial melting temperature 85 ℃, average length 9 mm) , Fumed silica 30 (hydrophilic type, specific surface area is 200m 2 / g), siliceous filler 40 expanded perlite (bulk density 60kg / m 3 ) and sunscreen 50 carbon black (CTAB adsorption specific surface area is 111.2m 2 / g, the coloring strength is 120.8%) according to the ratio of mass ratio 10:5:45:25:15 into the barrel-shaped container, use the stirring blade to mechanically pre-stir it for 10min, the stirring speed is 800r / min, to obtain fiber / powder mixture;

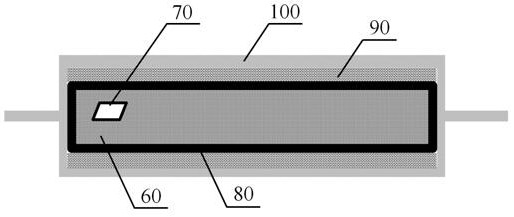

[0049] (2) Hot press molding of the mixture: put the fiber / powder mixture into a flat metal mold, and press it once with a press. The pressing time is 5min, and the pressurizing pressure is 2.0MPa to obtain a ...

Embodiment 2

[0064] The preparation method of fiber / powder composite core material comprises the steps:

[0065] (1) Mixing of fiber and powder: viscose chopped strands 10 (average diameter 9 μm, average length 6 mm), low-melting polyester fiber 20 (skin-core type, initial melting temperature 110 ℃, average length 5 mm) ), fumed silica 30 (hydrophilic type, specific surface area is 200m 2 / g), siliceous filler 40 expanded perlite (bulk density 60kg / m 3 ), expanded vermiculite (bulk density 180kg / m 3 ) and opacifying agent 50SiC powder (90% purity, 7.5μm average particle size) are poured into a drum-shaped container at a mass ratio of 5:5:40:30:10:10, and mechanically pre-treated by stirring blades. Stir for 5min, the stirring speed is 1800r / min, to obtain the fiber / powder mixture;

[0066] (2) Hot press molding of the mixture: put the fiber / powder mixture into a flat metal mold, and use a press to pressurize it twice in stages. The pressurized pressure is 2.0MPa, the holding time is 5m...

Embodiment 3

[0081] The preparation method of fiber / powder composite core material comprises the steps:

[0082] (1) Mixing of fiber and powder: chopped ceramic fiber 10 (average diameter 6 μm, average length 6 mm), low melting point polyester fiber 20 (full melting type, initial melting temperature 150 ℃, average length 5 mm) ), fumed silica 30 (hydrophilic type, specific surface area is 200m 2 / g), siliceous filler 40 expanded vitrified microbeads (bulk density 180kg / m 3) and opacifying agent 50SiC powder (purity 90%, average particle size 15μm) were poured into a drum-shaped container at a mass ratio of 8:8:34:30:20, and mechanically pre-stirred for 5 minutes with a stirring blade. The stirring speed is 600r / min to obtain the fiber / powder mixture;

[0083] (2) Hot press molding of the mixture: put the fiber / powder mixture into an arc-shaped metal mold, and press it three times with a press. The pressure of pressing is 2.0MPa, the holding time is 5min, the pressure of the second press...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com