Preparation method and application of nickel selenide/molybdenum selenide composite nano electrocatalyst

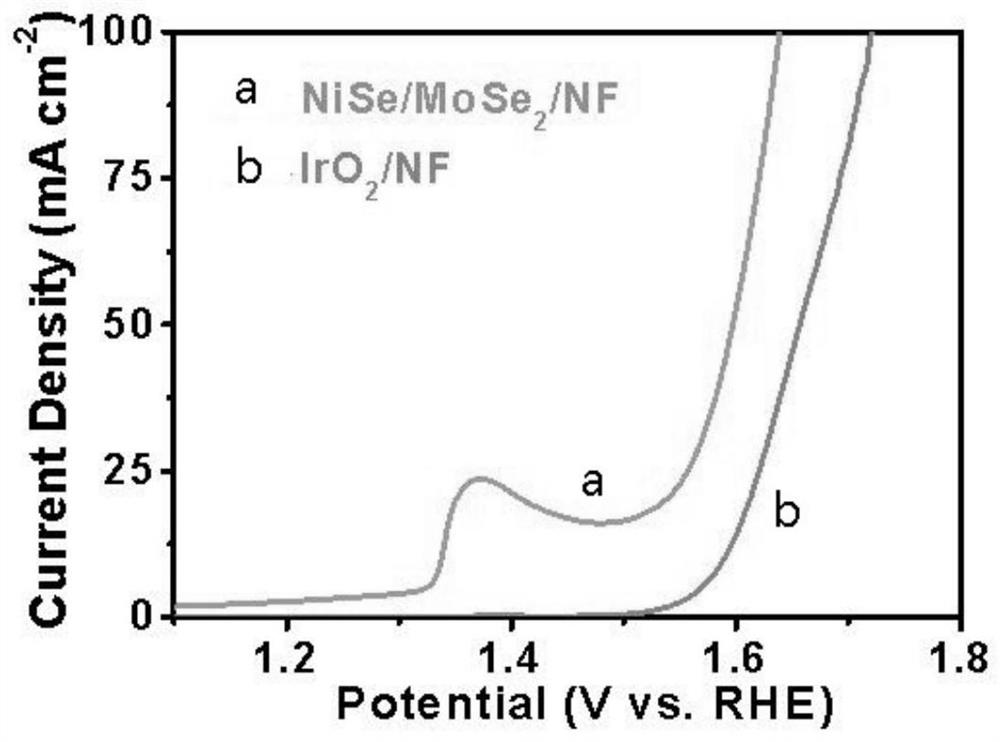

An electrocatalyst, molybdenum selenide technology, applied in physical/chemical process catalysts, chemical instruments and methods, chemical/physical processes, etc., can solve the problems of poor conductivity, poor performance, difficult preparation of electrocatalytic materials, etc., to reduce energy. , The distribution of components is uniform, which is beneficial to the effect of ion transmission

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

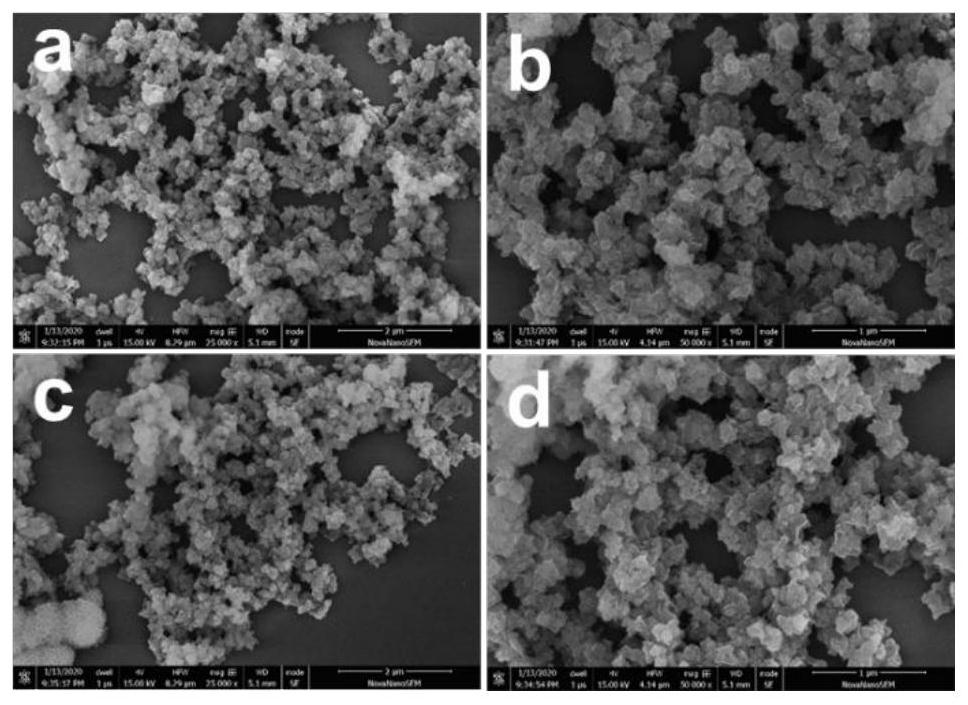

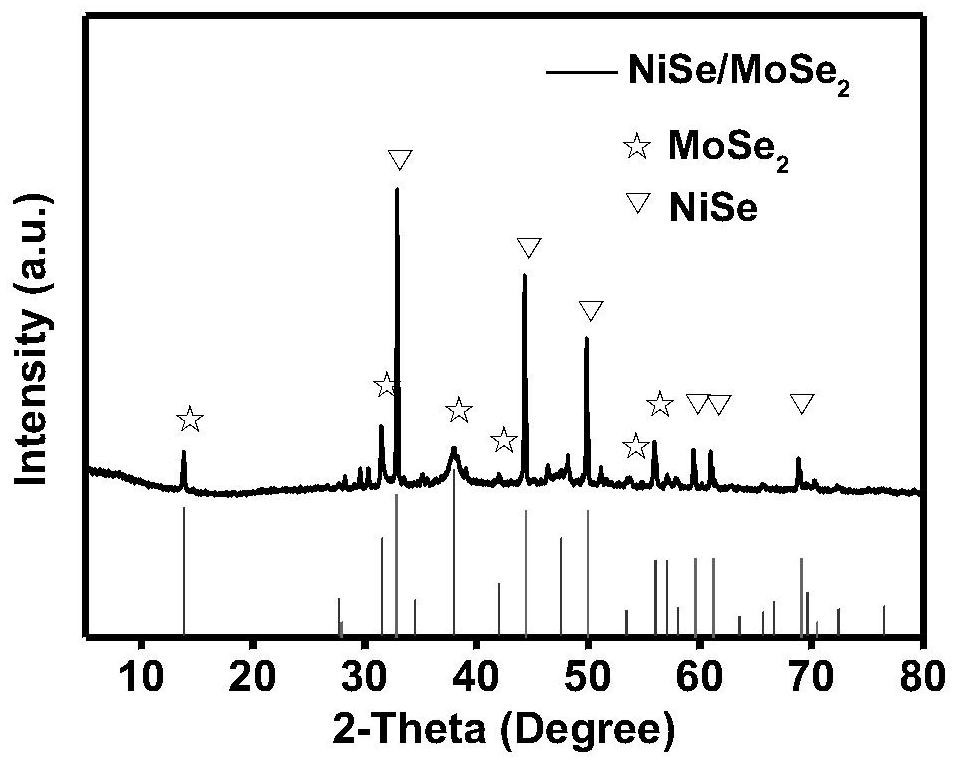

Embodiment 1

[0031] (1) Take a clean beaker, add 50ml deionized water, weigh 0.42g Na 2 MoO 4 2H 2 O, and 0.3g Ni(NO 3 ) 2 ·6H 2 O was poured into deionized water, weighed 0.475g 2-methylimidazole and 0.99g Na 2 SO 4 Pour into the mixed solution of metal salts and ultrasonically dissolve. Pour it into a 100ml reaction kettle, place it in an oven and heat it to 120°C, react for 8 hours, and cool down to room temperature naturally after the reaction stops. Take out the solution after the reaction, centrifuge, and centrifuge and wash the lower part of the precipitate with deionized water for 3 times, and vacuum-dry at 60°C for 12 hours to obtain the precursor;

[0032] (2) Put the precursor obtained in step (1) in N 2 Under the atmosphere, the temperature was raised to 700°C at a rate of 10°C / min, kept for 2 hours, and then cooled to 500°C at a rate of 10°C / min, and the gas was switched to H 2 / Ar 2 Mixed gas (H 2 and Ar 2 The volume ratio is 1:9), and then push the crucible conta...

Embodiment 2

[0045] 1) Take a clean beaker, add 50ml deionized water, weigh 0.42g Na 2 MoO 4 2H 2 O, and 0.15g Ni(NO 3 ) 2 ·6H 2 Pour O into deionized water, weigh 0.3g 2-methylimidazole and 0.99g Na 2 SO 4 Pour into the mixed solution of metal salts and ultrasonically dissolve. Pour it into a 100ml reaction kettle, place it in an oven and heat it to 180°C, react for 6 hours, and cool down to room temperature naturally after the reaction stops. Take out the solution after the reaction, centrifuge, and centrifuge and wash the lower part of the precipitate with deionized water for 3 times, and vacuum-dry at 60°C for 12 hours to obtain the precursor;

[0046] (2) Put the precursor obtained in step (1) in N 2 Under the atmosphere, the temperature was raised to 600°C at a rate of 5°C / min, kept for 4 hours, and then cooled to 300°C at a rate of 1°C / min, and the gas was switched to H 2 / Ar 2 Mixed gas (H 2 and Ar 2 The volume ratio is 1:9), and then push the crucible containing 100mg ...

Embodiment 3

[0049] 1) Take a clean beaker, add 50ml deionized water, weigh 0.38g Na 2 MoO 4 2H 2 O, and 0.2g Ni(NO 3 ) 2 ·6H 2 O was poured into deionized water, weighed 0.3g 2-methylimidazole and 0.8g Na 2 SO 4 Pour into the metal salt mixed solution, ultrasonically dissolve, pour into a 100ml reaction kettle, place in an oven and heat to 80°C, react for 12h, and naturally cool down to room temperature after the reaction stops. Take out the solution after the reaction, centrifuge, and centrifuge and wash the lower part of the precipitate with deionized water for 3 times, and vacuum-dry at 60°C for 12 hours to obtain the precursor;

[0050] (2) Put the precursor obtained in step (1) in N 2 Under the atmosphere, the temperature was raised to 600°C at a rate of 5°C / min, kept for 4 hours, and then cooled to 300°C at a rate of 1°C / min, and the gas was switched to H 2 / Ar 2 Mixed gas (H 2 and Ar 2 The volume ratio is 1:9), and then push the crucible containing 150mg selenium powder ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com