Oil sludge pyrolysis treatment device and process

A treatment device and oil sludge technology, applied in the field of oil sludge pyrolysis treatment device, can solve the problems of technical requirements for easy porcelain coking of baked dry soil, harm to human health and sustainable development, and high selectivity for high-efficiency microorganisms, so as to ensure stability. and continuous operability, preventing ceramic agglomeration, and reducing operating costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

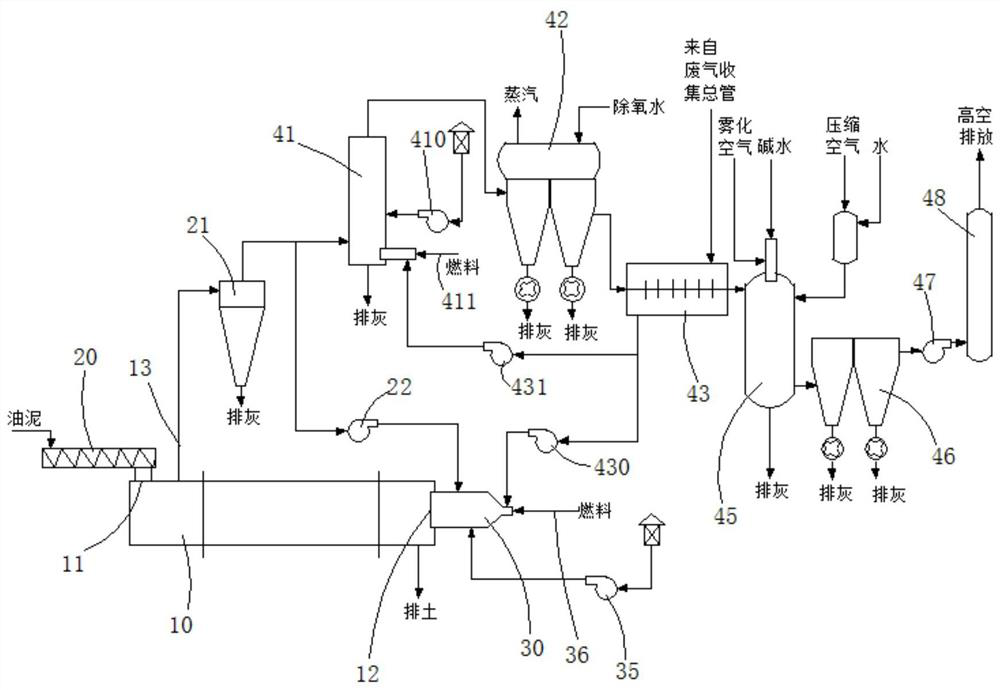

[0042] Below, in conjunction with accompanying drawing and specific embodiment, the present invention is described further:

[0043] see figure 1, is a schematic process flow diagram of a sludge pyrolysis treatment device of the present invention. The sludge pyrolysis treatment device includes a sludge pyrolysis system, a pyrolysis gas circulation system, a flue gas waste heat recovery system, and a flue gas treatment system connected in sequence. The pyrolysis system is used for pyrolysis through direct contact between hot flue gas and oil sludge; the pyrolysis gas circulation system is used to remove the ash entrained by the pyrolysis gas, and return part of the pyrolysis gas to the oil sludge pyrolysis system for recycling. utilization; the flue gas waste heat recovery system is used to burn the pyrolysis gas again, remove the flammable and harmful substances contained in the flue gas, and recycle the heat of the generated high-temperature flue gas; the flue gas treatment s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com