Rice slow-release fertilizer and preparation and application methods thereof

A technology of slow-release fertilizer and rice, which is applied in the field of rice slow-release fertilizer and its preparation and application, and can solve the problems of no layering effect and waste of fertilizer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

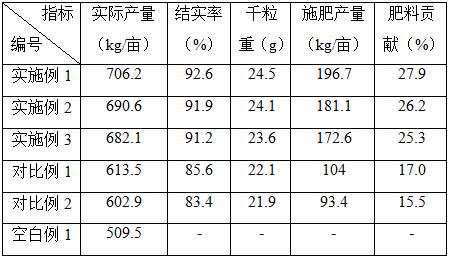

Examples

Embodiment 1~3

[0062] Table 1 shows the raw material components and parts by weight in Examples 1-3 of a slow-release fertilizer for rice.

[0063] Table 1 The ingredients and parts by weight of each raw material in Examples 1-3 of a slow-release fertilizer for rice

[0064]

[0065] Note: "-" in the table means not added.

[0066] In Example 1 of a slow-release fertilizer for rice, the slow-release fertilizer for rice is spherical particles, which are sequentially from inside to outside: nutrient core, inner coating, fertilizer layer and outer coating; the average particle diameter of the nutrient core is 3.5 mm; the average thickness of the inner coating is 0.2mm; the average thickness of the fertilizer layer is 0.4mm; the average thickness of the outer coating is 0.2mm.

[0067] In Example 2 of a slow-release fertilizer for rice, the slow-release fertilizer for rice is spherical particles, which are sequentially from inside to outside: nutrient core, inner coating, fertilizer layer an...

Embodiment 1

[0070] (1) According to the components and weight parts of Example 1 in Table 1, after mixing nitrogen, phosphorus and potassium compound fertilizer, trace element fertilizer, silicon fertilizer, calcium fertilizer, magnesium fertilizer and sulfur fertilizer, the inclination angle is 40°, and the rotation speed is 10r / min, temperature is 50°C, steam pressure is 0.3MPa, carry out steam drum granulation for 5min, sieve until the average particle size is 3.5mm, and obtain nutrient core;

[0071] (2) According to the components and weight parts of Example 1 in Table 1, dissolve sodium alginate, carboxymethyl chitosan and nitrification inhibitor in 320 parts by weight of water, spray at 70 ° C with a flow rate of 40 kg / min, At a rotating speed of 12r / min, heat and rotate the surface of the nutrient core obtained in step (1) until the spraying is completed and the moisture content is ≤ 4%, and the nutrient core coated with the inner coating is obtained;

[0072] (3) According to the...

Embodiment 2

[0075] (1) According to the components and weight parts of Example 2 in Table 1, after mixing nitrogen and potassium compound fertilizer, trace element fertilizer, silicon fertilizer, calcium fertilizer, magnesium fertilizer and sulfur fertilizer, the inclination angle is 35° and the rotation speed is 8r / min, at a temperature of 40°C and a steam pressure of 0.2 MPa, perform steam drum granulation for 4 minutes, and sieve until the average particle size is 3.0 mm to obtain nutrient cores;

[0076] (2) Dissolve sodium alginate, carboxymethyl chitosan and nitrification inhibitor in 150 parts by weight of water according to the components and parts by weight of Example 2 in Table 1, spray at 60°C with a flow rate of 30kg / min , at a rotating speed of 8r / min, heat and rotate the surface of the nutrient core obtained in step (1) until the spraying is completed and the moisture content is ≤ 3%, and the nutrient core coated with the inner coating is obtained;

[0077] (3) According to...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com