Preparation method and application method of phenolic resin with hollow shell structure

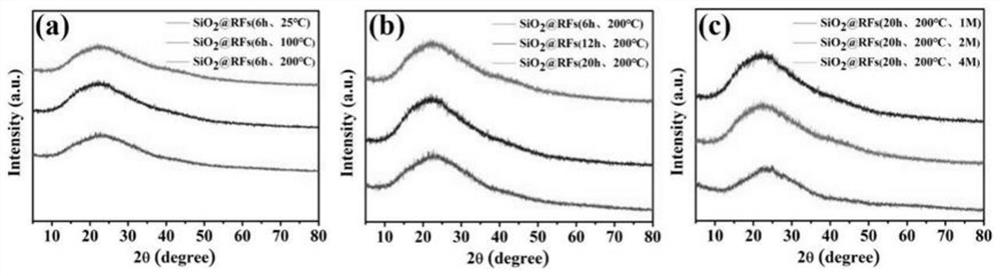

A phenolic resin and hollow shell technology, applied in the field of nanomaterials, can solve the problems of insufficient oxygen mass transfer and high recombination rate of photogenerated electron holes, and achieve the effects of simple and convenient experimental steps, economical and readily available raw materials, and complete hollow shell structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-3

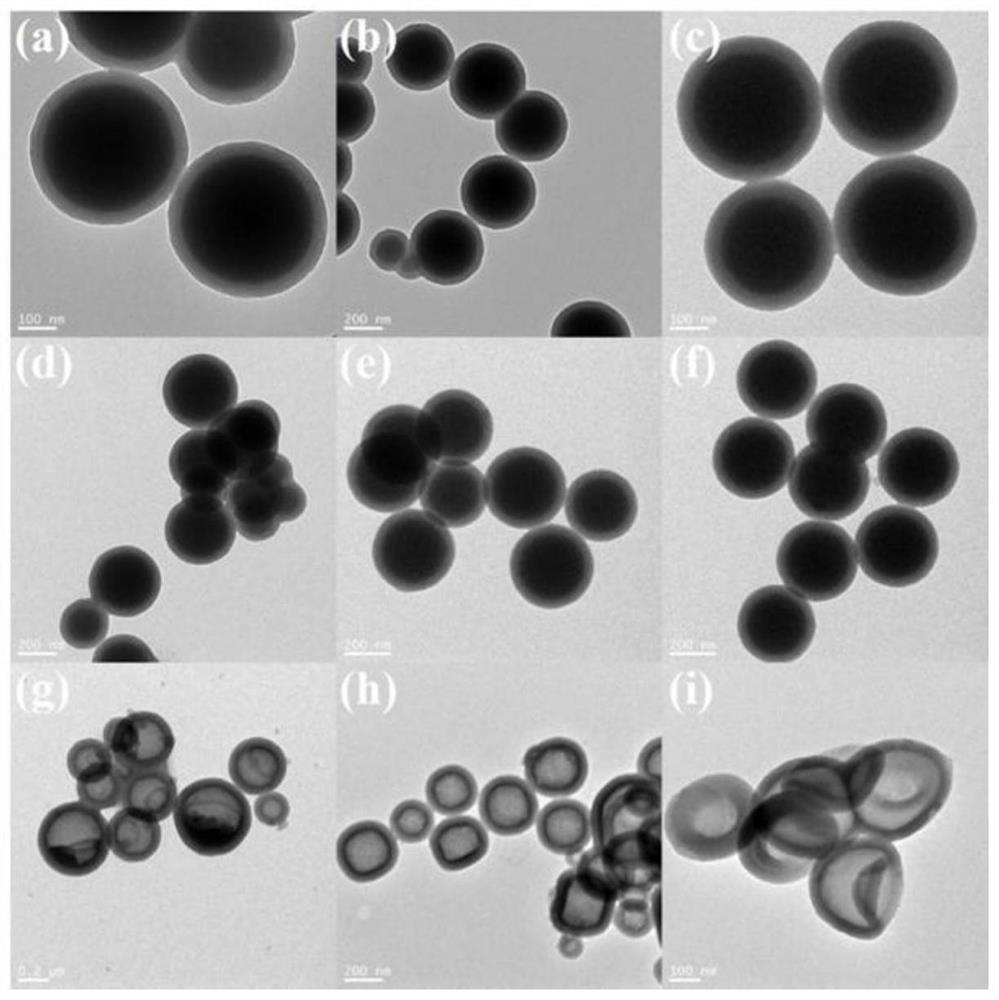

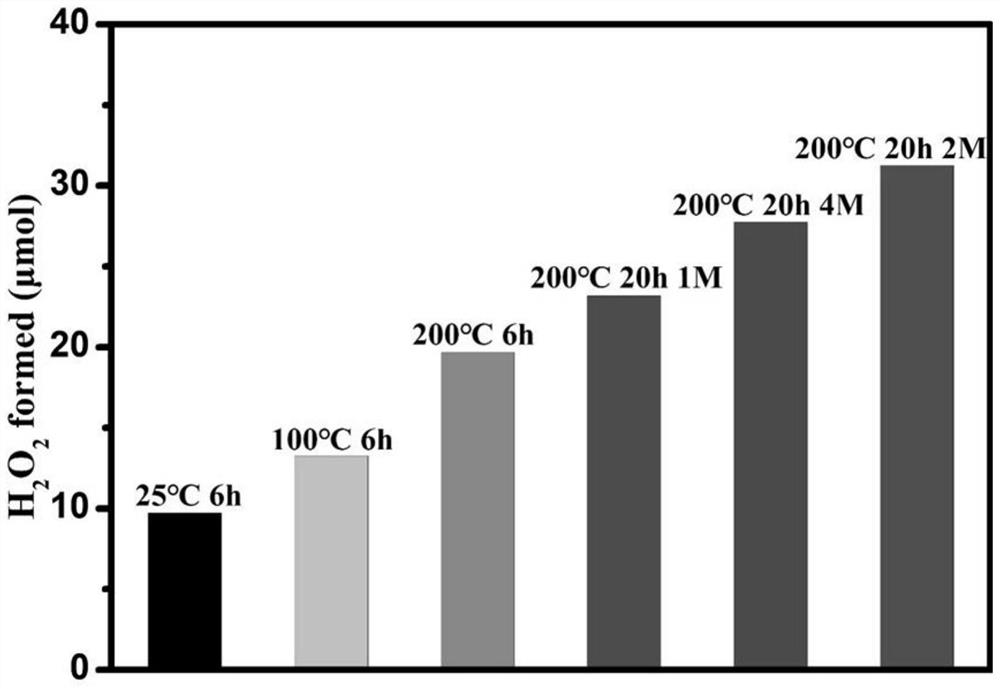

[0059] To prepare hollow shell structure phenolic resin, the concentration of ammonium bifluoride aqueous solution is respectively (1M, 2M, 4M).

[0060] To prepare phenolic resin grown on the surface of silica nanoparticles, the temperature of the hydrothermal reaction is 200°C, and the hydrothermal time is 20h:

[0061] Add 70ml of absolute ethanol and 10ml of deionized water into a round bottom flask, and stir at room temperature for 5min. Then add 6ml of tetraethyl silicate, stir for 40min, then add 3ml of ammonia water, and continue stirring for 1h. The reacted solution was centrifuged, washed with ethanol and water three times until the supernatant was neutral, and silica nanoparticles were obtained. Add 0.8 g of the prepared silicon dioxide nanoparticles into 30 ml of deionized water and 70 ml of absolute ethanol, and sonicate at room temperature for 40 min to disperse the nanoparticles evenly. Add 3.2g of cetyltrimethylammonium bromide CTAB to the dispersion liquid, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com