Refining process and equipment for batch production of bentazone

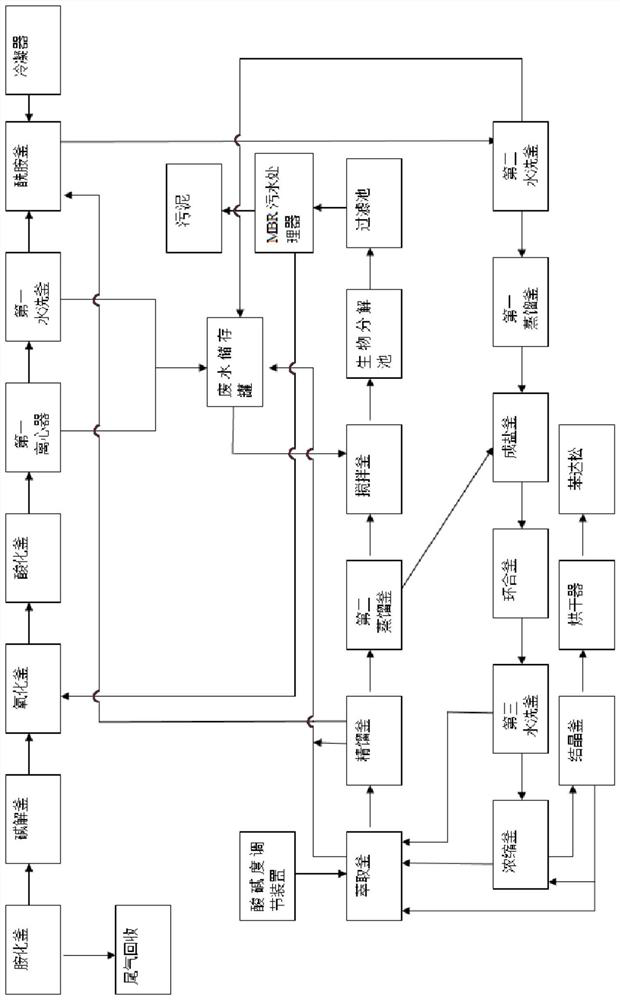

A bendazone and mass production technology, which is applied to the refining process and equipment field of mass production of bentazone, can solve the problems of difficult purification, analysis and quantification, difficult synthesis, and strong corrosion of intermediates, so as to improve the utilization rate of raw materials , Improve product purity, improve the effect of fineness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0030] Embodiment: a kind of refining process for mass production of bentazone specifically comprises the steps:

[0031] (1) Amination: Put phthalic anhydride in the amination kettle, raise the temperature to 250°C, and pass the liquid ammonia into the amination kettle after being vaporized by the vaporizer. Phthalimide, the tail gas produced by the reaction is condensed to recover ammonia water;

[0032] (2) Alkaline hydrolysis and oxidation: drop into liquid caustic soda in the alkaline hydrolysis kettle, then drop into phthalimide, stir and react at room temperature, after the reaction finishes, the alkaline hydrolysis solution is transferred to the oxidation kettle;

[0033] Put water into the oxidation kettle, lower the temperature to below 5°C, add sodium hypochlorite, and finish when the pH=11, then transfer to the acidification kettle;

[0034] (3) Acidification, centrifugation, washing and drying: the acidification kettle is heated up to 30°C, sulfuric acid is added...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com